- Joined

- Sep 21, 2017

- Messages

- 96

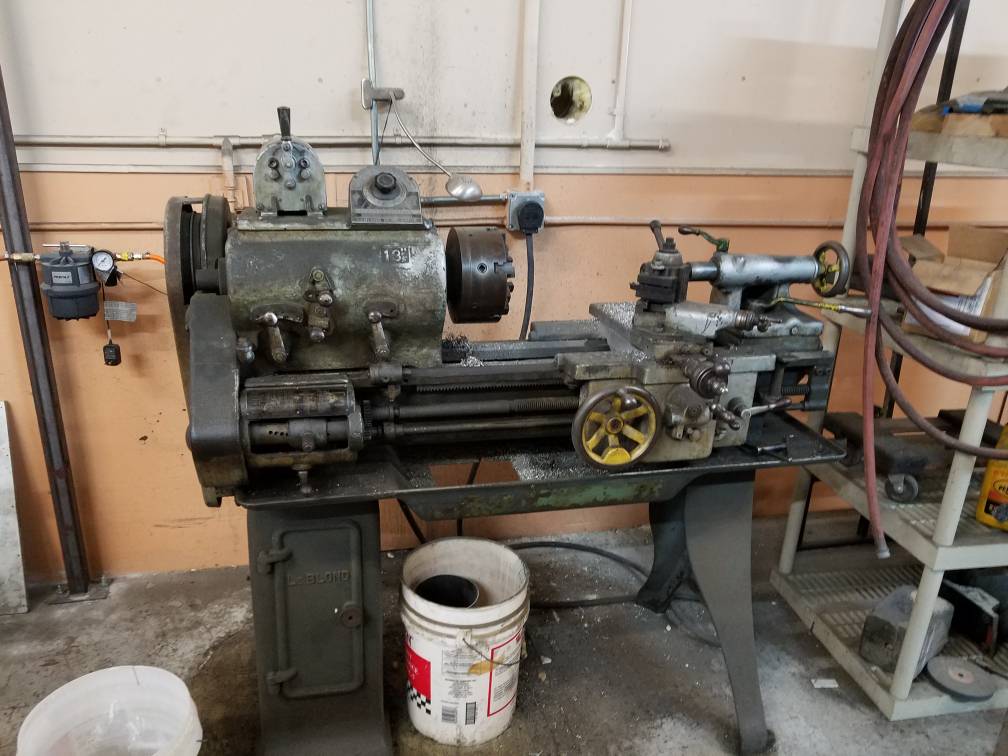

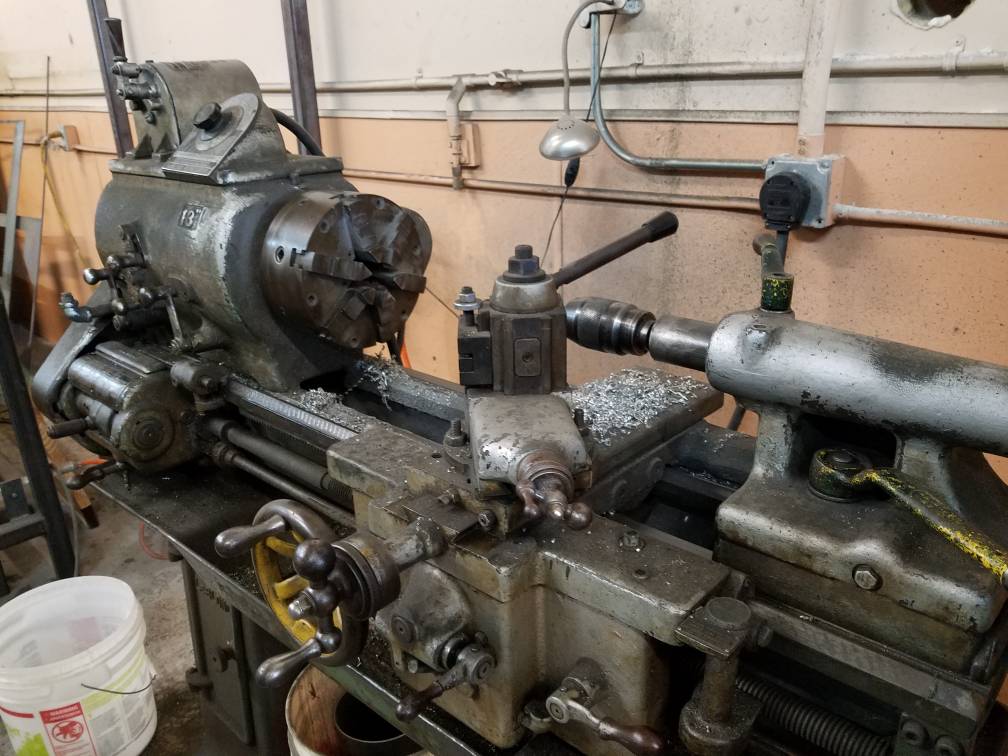

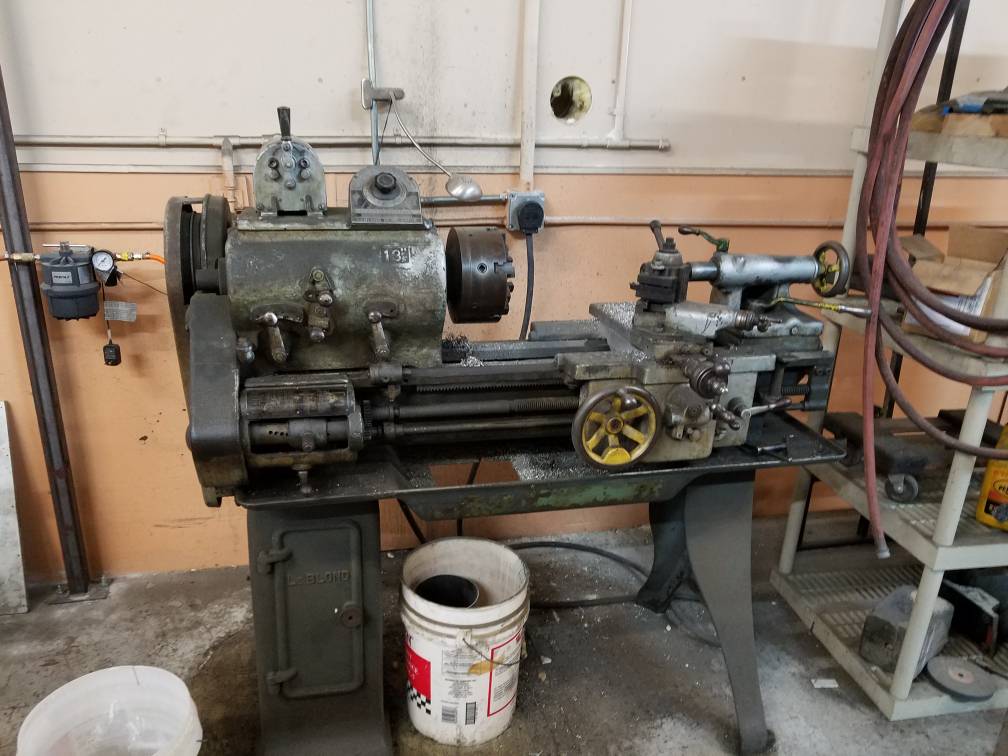

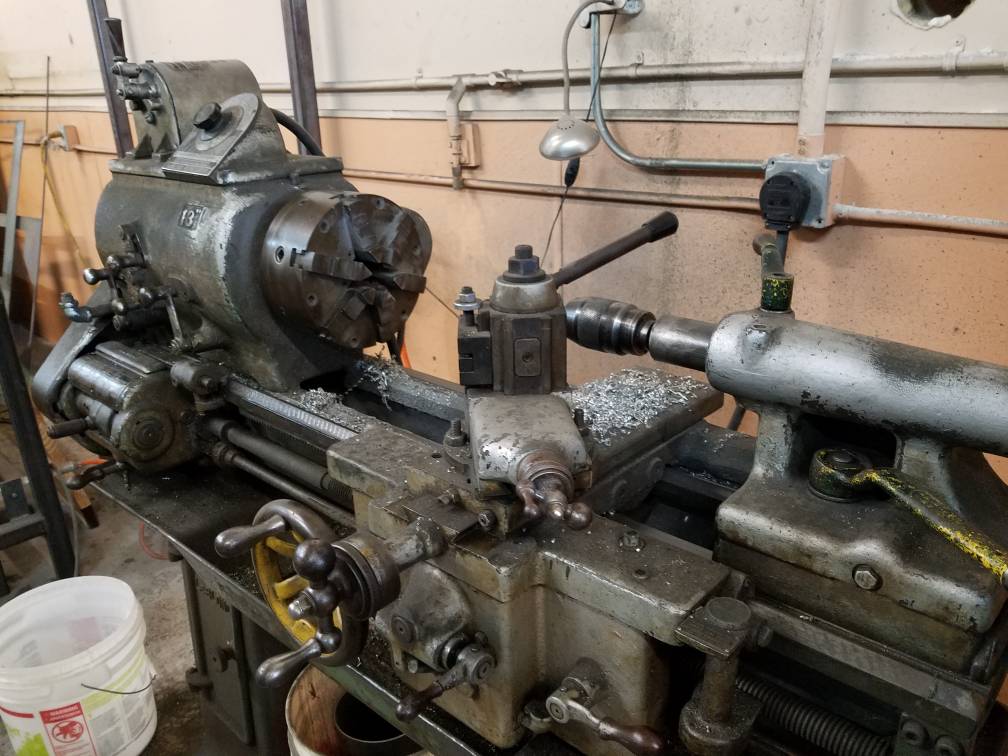

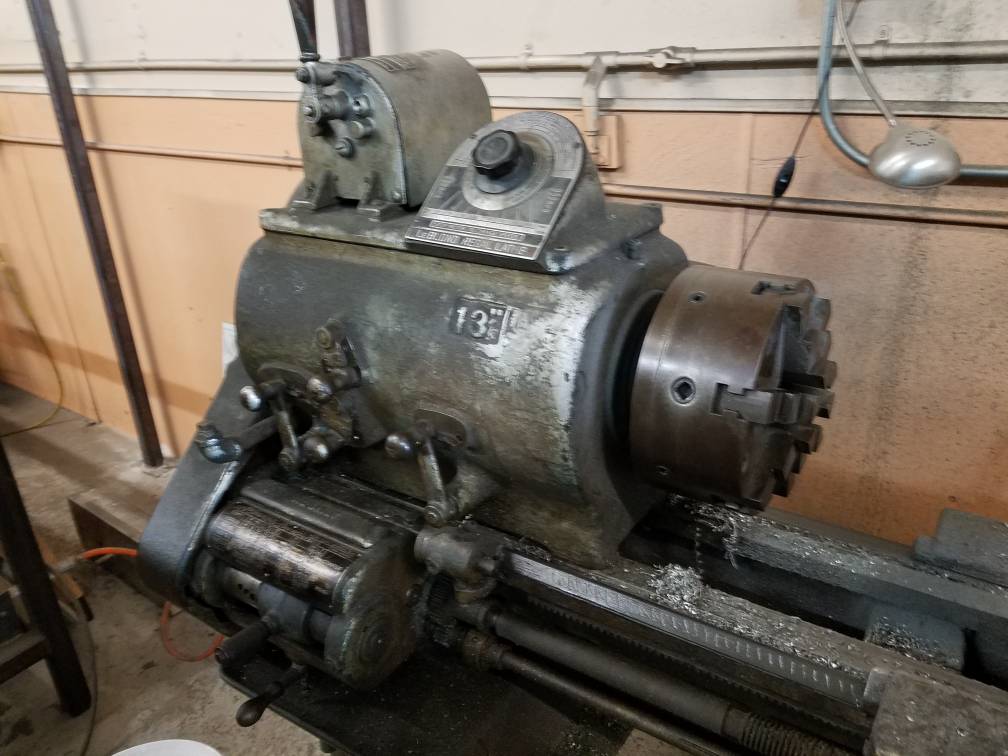

I am the proud new owner of a Regal 13" and would like to know more about it. I have been doing the usual searches on Google, EBay, Vintage Machinery, etc and found some interesting and useful facts. I totally appreciate the speed limitations and that's not a problem, as I have a 9" South Bend which I use for smaller parts.

The lathe is equipped with 3 phase 3/4 hp motor, which I intend to drive with a VFD. It runs so well I don't see the value in changing it to single phase. It came, basically with no tooling, but has a decent qctp, and an 8" 6 jaw chuck (needs clean and lube). Wear, backlash etc are reasonable so I am hopeful for accurate work. Of course I have no idea yet what that work will turn out to be yet. Honestly, I bought it based on the price ($200), and it being bigger and heavier than my South Bend.

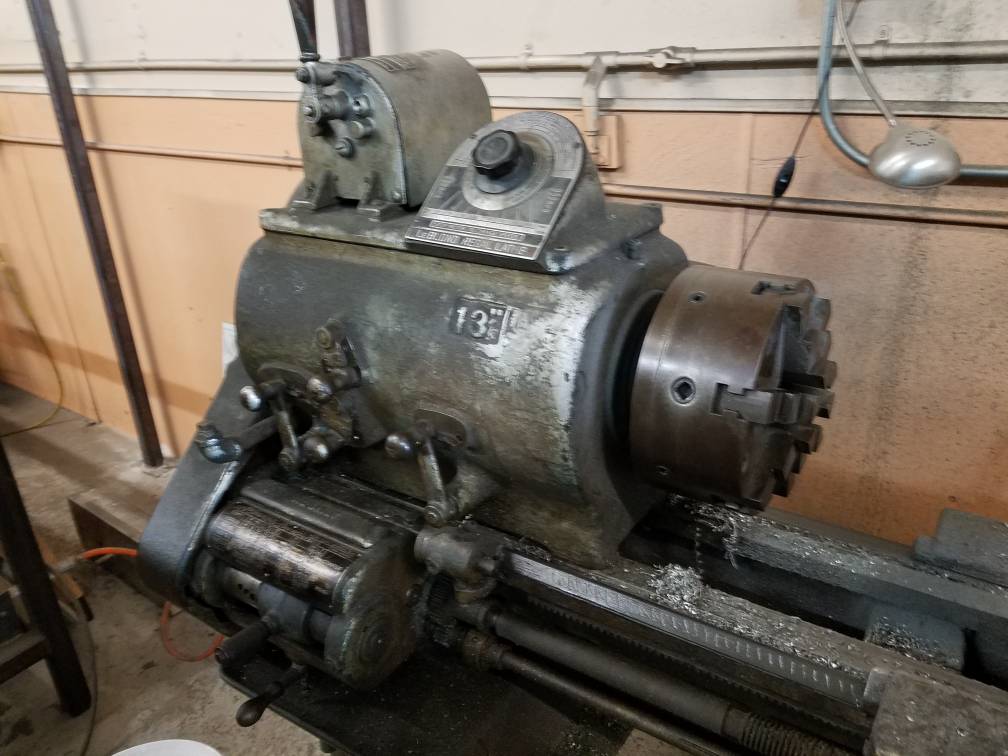

So, a couple of pictures taken where I bought it, and a picture of the numbers on the bed. Part of this is the serial number but can someone decode the whole thing for me?

I will not be able to run it in my shop until I get a VFD installed, but cleaning and checking out will start soon.

Any help and guidance is welcome.

Sent from my SM-G930T using Tapatalk

The lathe is equipped with 3 phase 3/4 hp motor, which I intend to drive with a VFD. It runs so well I don't see the value in changing it to single phase. It came, basically with no tooling, but has a decent qctp, and an 8" 6 jaw chuck (needs clean and lube). Wear, backlash etc are reasonable so I am hopeful for accurate work. Of course I have no idea yet what that work will turn out to be yet. Honestly, I bought it based on the price ($200), and it being bigger and heavier than my South Bend.

So, a couple of pictures taken where I bought it, and a picture of the numbers on the bed. Part of this is the serial number but can someone decode the whole thing for me?

I will not be able to run it in my shop until I get a VFD installed, but cleaning and checking out will start soon.

Any help and guidance is welcome.

Sent from my SM-G930T using Tapatalk