- Joined

- Jul 8, 2015

- Messages

- 145

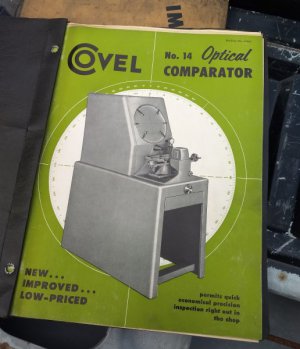

OK guys- Stumbled on to a FB Marketplace item- it led me to a sale at the old "Arrow Tool and Die Company" outside Philly... Guy there has already sold the building, and is having a bit of a "Fire sale" on remaining items- I bought some drills and micrometers... Went into the Quality control room and there sat a Covell 14 comparator- with a few extra lenses and plates. Machine powered up fine... Ive always wanted one- even though I cant USE one (Im still new in the grand scheme of making chips...)

Anyway- machine is home... I feel like I got a steal on it- and for it to sit, I figure I will have time to learn it...

My questions are:

1- I eventually want to make clock gearing and watch gears and smaller parts- Did I just go "WAY OVERBOARD" for this?

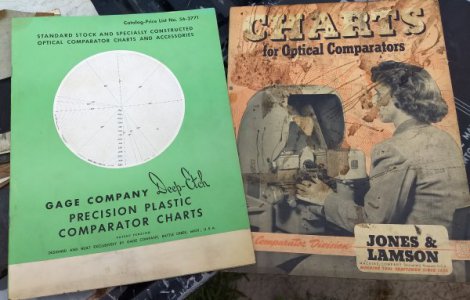

2- Any recommended old school texts or books on the care and feeding of these beasties?

Yes, I run the "Orphanage for Old Iron and Home-Shop Misfit Tools" If you have to ask...

Pics to follow

Anyway- machine is home... I feel like I got a steal on it- and for it to sit, I figure I will have time to learn it...

My questions are:

1- I eventually want to make clock gearing and watch gears and smaller parts- Did I just go "WAY OVERBOARD" for this?

2- Any recommended old school texts or books on the care and feeding of these beasties?

Yes, I run the "Orphanage for Old Iron and Home-Shop Misfit Tools" If you have to ask...

Pics to follow