- Joined

- Jul 14, 2017

- Messages

- 2,446

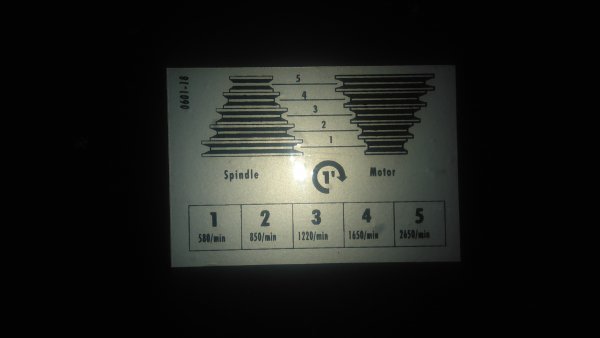

Today i bought this drill press at the local tool/ flea market, it was very cheap partly because of all the rust but more because the seller thought is not working, i spotted that the security tab on the belt cover was bent and knowing that i decided to take a gamble wich paid off because when got it home i straighten the tab and is working perfectly. This is a generic china made machine, i don't expect much from it, i plan to do as little improvements or modifications on it just to use it for smaller jobs. The plan now is to take it apart undo the neglect from the previous owner and found and make a holder to use it in my shop.