Hey all

This week I traded up from a 7x14 mini to a pretty much new PM1030V. Excited to set it up and get advice here.

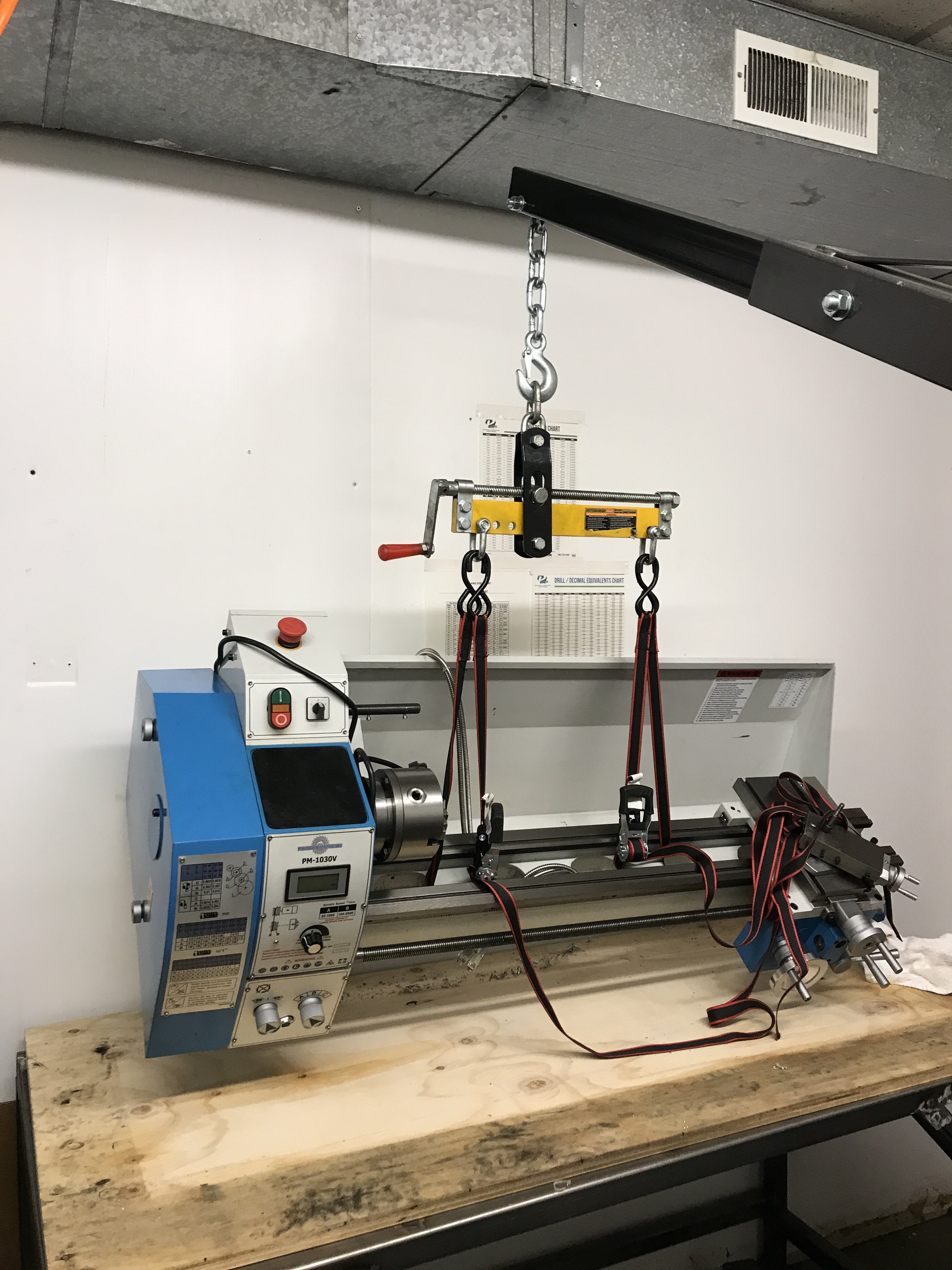

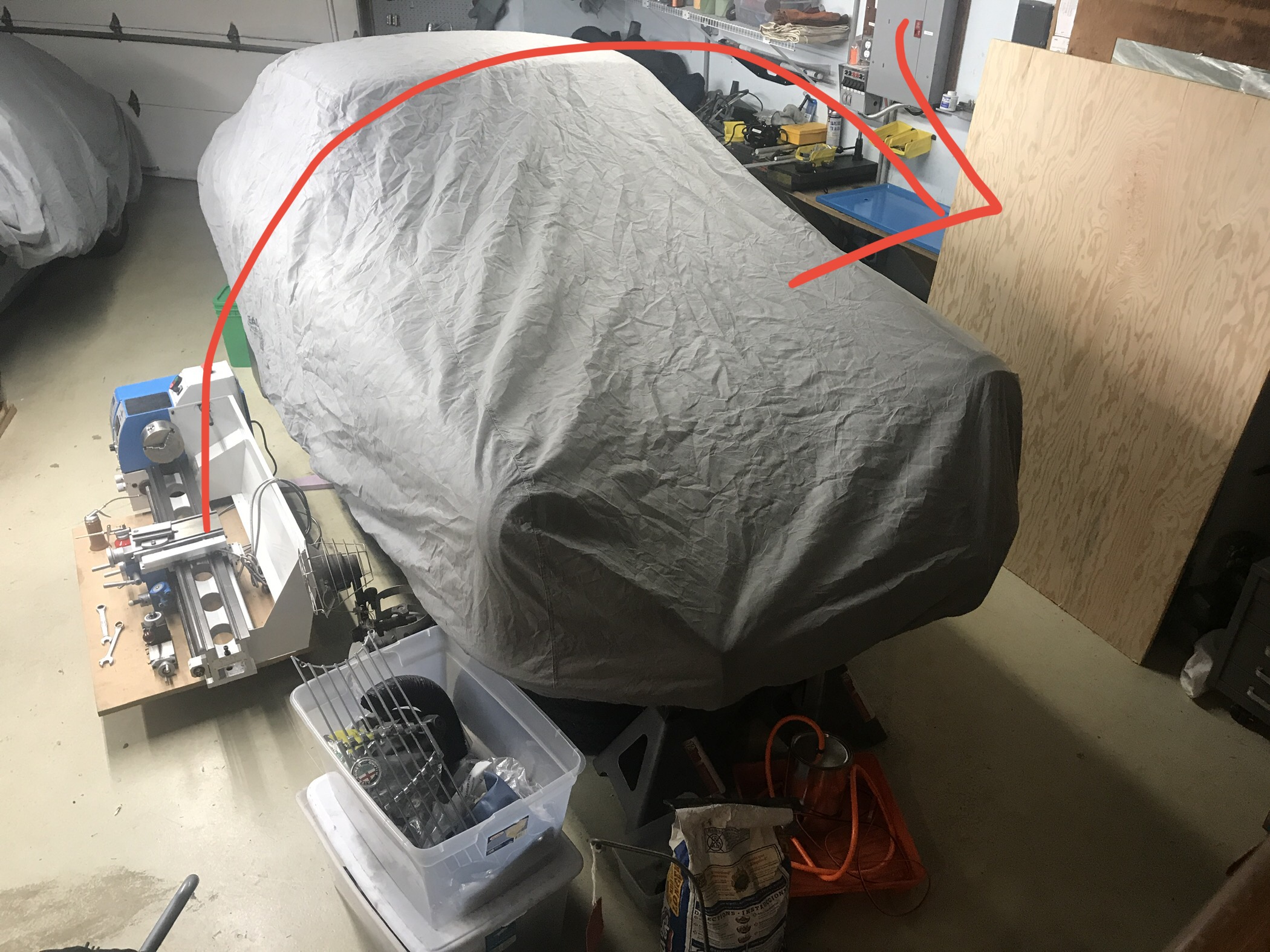

First it needs to arrive at its final resting place. I loaded/unloaded with with an engine crane (first pic) and its now on a dolly (second pic). The only problem is that there is a suspension-less project car entirely blocking crane access from the lathe to its bench (see pic). I have the tail stock, compound removed. Could remove saddle I suppose. Has anyone and a few friends lifted one with no hydraulic assistance? I suppose the backup plan is the ATV jack but that won't be a walk in the park either. Before you ask: its a decent slog to get the suspensionless car on wheels or a dolly so its not the preferred technique...

This week I traded up from a 7x14 mini to a pretty much new PM1030V. Excited to set it up and get advice here.

First it needs to arrive at its final resting place. I loaded/unloaded with with an engine crane (first pic) and its now on a dolly (second pic). The only problem is that there is a suspension-less project car entirely blocking crane access from the lathe to its bench (see pic). I have the tail stock, compound removed. Could remove saddle I suppose. Has anyone and a few friends lifted one with no hydraulic assistance? I suppose the backup plan is the ATV jack but that won't be a walk in the park either. Before you ask: its a decent slog to get the suspensionless car on wheels or a dolly so its not the preferred technique...