I picked this lathe up during the pandemic and have been cleaning it up for my garage use. Have been having fun with it but am a little confused right now. I've cleaned out the headstock and changed the oil. Verified that the head runs well. Extensive scrubbing/cleaning (including a putrid archaeology dig into the coolant tank). This lathe was unfortunately damaged at some point in its life as the handles were bend when I bought it. My theory is that it wasn't completely dropped, but something whacked the apron and forced the saddle up since the front saddle gibs were broken. I tore down the apron completely, replaced all seals and bearings. Repaired and straightened the shafts, handles and replaced the carriage handle bushing and that all seems good now. My confusion is around assessing the way and saddle wear. I'm hoping some other Taki owners could provide some advice.

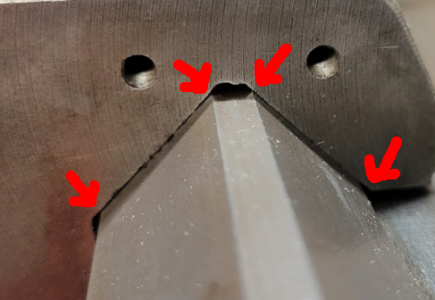

I made up some leveling screws and I have it leveled to around .002. I leveled it using the two flat ways. The saddle gib running surface under the bed appears to be unworn, so I took measurements of the saddle ways against that as a reference. I'm reading about .001" of wear in the bed on the flat way, and around .003" of wear on the front V way. Oddly the V angle gets narrower close to the headstock. A V block placed on the V way will rock about .002". Here's the odd part though: with the machine leveled across those flats, the cross ways on the saddle are off level about .02"! It is lower at the front V way. At first I assumed the saddle was just worn that amount, but there does not appear to be a wear ridge of any kind under the saddle.

Some of my assumptions here that maybe other owners can confirm or crush:

1. Are the tailstock ways in plane with the saddle ways? I assume that leveling across the two flats is a good leveling reference.

2. I assume that the saddle cross way is parallel to the flat ways on the bed? This isn't necessarily true but I don't know why it wouldn't be?

3. Is there any way that the saddle wouldn't have a wear ridge under it?

This situation has left me scratching my head. As with any old machine I have to consider "meddling" by previous owners which could easily have been misguided. I wonder if maybe the saddle was machined on the bottom to eliminate the wear ridge on the V, but then not brought back up again?

My inclination is to machine the bottom of the saddle, turcite it and bring it back level with the flat ways. If I'm going to that trouble I'm also thinking I may as well have the bed ground. So this is the rabbit hole I've been orbiting for the last few weeks on this project!

Google photos album of my journey thus far: https://photos.app.goo.gl/WFTk1gwRZgQgEQ8U7

I made up some leveling screws and I have it leveled to around .002. I leveled it using the two flat ways. The saddle gib running surface under the bed appears to be unworn, so I took measurements of the saddle ways against that as a reference. I'm reading about .001" of wear in the bed on the flat way, and around .003" of wear on the front V way. Oddly the V angle gets narrower close to the headstock. A V block placed on the V way will rock about .002". Here's the odd part though: with the machine leveled across those flats, the cross ways on the saddle are off level about .02"! It is lower at the front V way. At first I assumed the saddle was just worn that amount, but there does not appear to be a wear ridge of any kind under the saddle.

Some of my assumptions here that maybe other owners can confirm or crush:

1. Are the tailstock ways in plane with the saddle ways? I assume that leveling across the two flats is a good leveling reference.

2. I assume that the saddle cross way is parallel to the flat ways on the bed? This isn't necessarily true but I don't know why it wouldn't be?

3. Is there any way that the saddle wouldn't have a wear ridge under it?

This situation has left me scratching my head. As with any old machine I have to consider "meddling" by previous owners which could easily have been misguided. I wonder if maybe the saddle was machined on the bottom to eliminate the wear ridge on the V, but then not brought back up again?

My inclination is to machine the bottom of the saddle, turcite it and bring it back level with the flat ways. If I'm going to that trouble I'm also thinking I may as well have the bed ground. So this is the rabbit hole I've been orbiting for the last few weeks on this project!

Google photos album of my journey thus far: https://photos.app.goo.gl/WFTk1gwRZgQgEQ8U7

Last edited: