I needed to cut some keyways on the inside of bushings, actually for felts on the new worm drive bushings on a SB 9" lathe. I did not have a suitable tool holder so building one seemed like the first step. I ended up making 2 different holders that use the type of lathe boring bar that holds a small HSS bit. This shaper did not have any feature to lock the clapper box so that ability was added to both toolholders. Some sources recommend locking the clapper when cutting slots. The clapper box is attached with a screw to the compound slide. The tool holders can be attached either to the clapper or thru the clapper directly into the threaded hole in the slide. The first one started as a 1 1/8" boring bar. The cutting tip is a fixed distance from the clapper, sort of a compromise between desired stroke length and distance to the vise. The tool was ground to the width of the desired slot. The tool is advanced about 0.005" when it is at the start of each stroke so it takes some attention. Advancing the tool before it has exited the back of the bushing will break off the bit. I only did that once.

The left photo shows the 2 new holders as well as the one that came with the shaper all set up for the normal clapper type movement. The bottom one uses 5/8" boring bar that can be adjusted for length by extending the end into the shaper. The center photo shows the 2 new holders set up with the clapper clamped closed. The right photo is another view of the 5/8" boring bar holder.

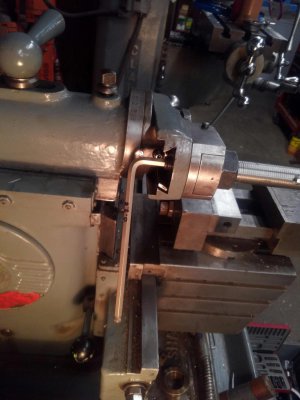

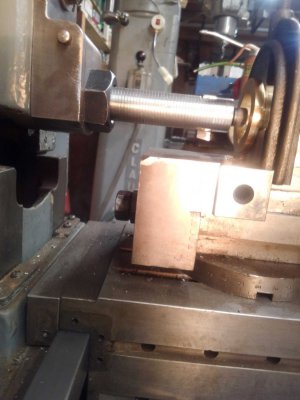

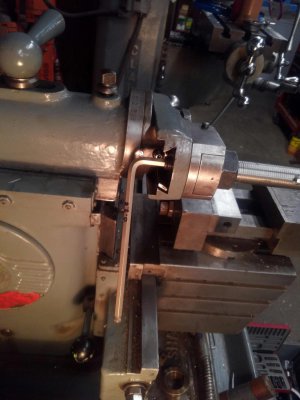

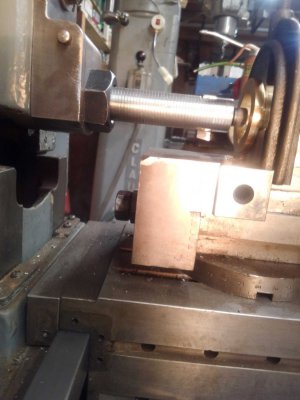

The next 3 photos show the shaper in action cutting the slot in the bushing.

Assembling the larger one in the clamped clapper configuration is a bit of a jigsaw puzzle. Remove cutting bit and nut, slide post in thru bottom side of clapper, reinstall nut and tool bit. Rotate and extend compound slide to get access to back side, install set screw tight into post, tighten the nut on the front while adjusting the cutting bit to vertical. I have a short video cutting the slot but not sure how to get it off my old phone and into the internet. It felt good to use the shaper, it has not seen a lot of use since getting the milling machine

The left photo shows the 2 new holders as well as the one that came with the shaper all set up for the normal clapper type movement. The bottom one uses 5/8" boring bar that can be adjusted for length by extending the end into the shaper. The center photo shows the 2 new holders set up with the clapper clamped closed. The right photo is another view of the 5/8" boring bar holder.

The next 3 photos show the shaper in action cutting the slot in the bushing.

Assembling the larger one in the clamped clapper configuration is a bit of a jigsaw puzzle. Remove cutting bit and nut, slide post in thru bottom side of clapper, reinstall nut and tool bit. Rotate and extend compound slide to get access to back side, install set screw tight into post, tighten the nut on the front while adjusting the cutting bit to vertical. I have a short video cutting the slot but not sure how to get it off my old phone and into the internet. It felt good to use the shaper, it has not seen a lot of use since getting the milling machine