I will do that.@BKDavis You might want to drop into the Precision Matthews sub-forum here. There's quite a number of PM mill owners there, plus the Precision Matthews folks drop by from time to time.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Newbie Question About Buying a Bench Mill

- Thread starter BKDavis

- Start date

I’m new to the forum and this is my first post. I almost immediately stumbled on this thread which had the exact answer I was looking for. Thanks!I think there's the possibility that it could drift if something was not adequately snugged down.

Also bear in mind that because there are slots to allow for titling, there's less overall casting to secure the head to the column.

I don't know that it's a major consideration on this form factor but something to consider.

I recall seeing a head casting crack on one of the videos from Meanwhile In the Garage series.

Different class of mill of course but a titling head nonetheless.

My Emco FB2 bench mill has got a tiltable head but so far I have used it just once to cut a slanted rectangular slot on a work piece. In this case the mill was used as a broaching machine so it's not a typical application. For me the major problem of tilting the head is locating. With the tool not mounted parallel to the Z axis, it's very difficult to bring the tool to the desired position relative to the work piece because common locating devices such as edge finders, Z-axis tool setters are not usable. Using a tiltable vise is much easier but the mill head will have to be raised to a higher position which may affect rigidity for light machines.

Last edited:

Thanks for the reply. I’ve used a mill for several years and haven’t run across a situation that couldn’t be handled without the need to tilt the head. In all the countless videos I’ve watched I’ve never seen the head tilted. Your picture is the first. Other than the Sieg SX2.7 and derivatives I don’t know of any fixed column mills in the 250-300lb class. If anyone know of others, I’d appreciate the input. Thanks!My Emco FB2 bench mill has got a tiltable head but so far I have used it just once to cut a slanted rectangular slot on a work piece. In this case the mill was used as a broaching machine so it's not a typical application. For me the major problem of tilting the head is locating. With the tool not mounted parallel to the Z axis, it's very difficult to bring the tool to the desired position relative to the work piece because common locating devices such as edge finders, Z-axis tool setters are not usable. Using a tiltable vise is much easier but the mill head will have to be raised to a higher position which may affect rigidity for hobby-grade machines.

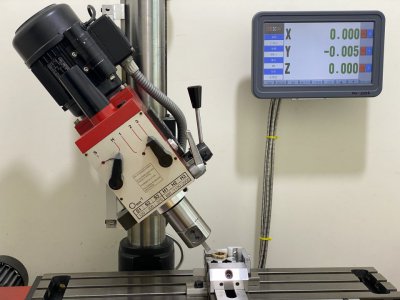

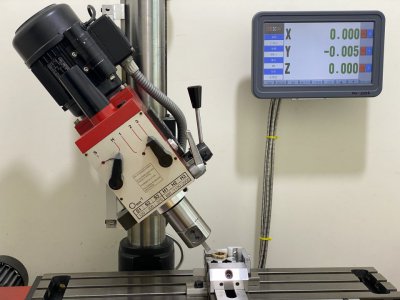

View attachment 390568

- Joined

- Jun 27, 2016

- Messages

- 378

I have tilted the head a couple of times to cut a trough using a regular end mill. All of my mills will tilt the head (Emco and the Deckels). On the Deckel FP-2NC there is a lock to put it back in tram.

Very few new mills available to buy just now even though I could use an upgrade. Guess it will give me some more time to look around. Thanks for all your help.I have tilted the head a couple of times to cut a trough using a regular end mill. All of my mills will tilt the head (Emco and the Deckels). On the Deckel FP-2NC there is a lock to put it back in tram.

- Joined

- Nov 17, 2017

- Messages

- 1,525

Thanks for the reply. I’ve used a mill for several years and haven’t run across a situation that couldn’t be handled without the need to tilt the head.

I think most of us who have angled the head and then gone through the process of tramming in the head again, find ways to avoid doing this in the future.