- Joined

- Nov 3, 2021

- Messages

- 13

Hello everyone,

This is a partial reprint of my Say Hello post up in the newbie section.

I've been looking at a 1948 Bridgeport Round Ram M Head mill a local guy is selling from a deceased relative. The mill looks to be in good shape with a reasonable amount of light surface rust from 3 years of inactivity. Backlash is running between .0010 - .0015" at the center of X & Y travel but unfortunately, I couldn't get a feel for the end of travel because the mill is hemmed in with other equipment. From the lack of tooling found I can only assume that the previous owner used it primarily as a drill press.

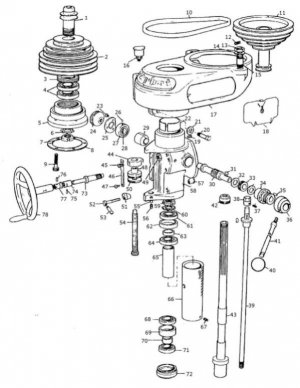

There are a couple of issues with the mill however. One being that the previous owner was an electrician's nightmare from the look of the wiring in the shop. As of yet, I have no way of powering the mill up and with the motor cover missing somewhere in the piles of unnamed junk, I've got no way of knowing what voltage and amp draw it is. It is one of the smaller pancake style motors which I assume is 1/2 hp and it turns freely running a flat belt step pulley. The other issue is that it is either missing the drawbar or, if Bridgeport made one, a solid spindle. The top of the spindle ends with the typical spline with about 3/4" worth of thread and nothing else. Photos I've been able to find suggest a nut over these threads with the drawbar passing thru. There is a Jacob's chuck in the mill and is in there solid. On last inspection, I didn't think to climb up to see if the spindle was hollow, assuming that they were all hollow and the drawbar was missing also leaving me to guess whether it's a MT2 or B&S7 taper. Any ideas?

Since I have very little headspace in my basement, less than 7', this little mill will fit perfect. I contacted both H&W Machinery and CE Wood Machinery and inquired about value and based on their recommendations, the owner and I have agreed to a price of $500 for the mill and large vise already attached. What is everyone's thoughts on that?

Thanks

This is a partial reprint of my Say Hello post up in the newbie section.

I've been looking at a 1948 Bridgeport Round Ram M Head mill a local guy is selling from a deceased relative. The mill looks to be in good shape with a reasonable amount of light surface rust from 3 years of inactivity. Backlash is running between .0010 - .0015" at the center of X & Y travel but unfortunately, I couldn't get a feel for the end of travel because the mill is hemmed in with other equipment. From the lack of tooling found I can only assume that the previous owner used it primarily as a drill press.

There are a couple of issues with the mill however. One being that the previous owner was an electrician's nightmare from the look of the wiring in the shop. As of yet, I have no way of powering the mill up and with the motor cover missing somewhere in the piles of unnamed junk, I've got no way of knowing what voltage and amp draw it is. It is one of the smaller pancake style motors which I assume is 1/2 hp and it turns freely running a flat belt step pulley. The other issue is that it is either missing the drawbar or, if Bridgeport made one, a solid spindle. The top of the spindle ends with the typical spline with about 3/4" worth of thread and nothing else. Photos I've been able to find suggest a nut over these threads with the drawbar passing thru. There is a Jacob's chuck in the mill and is in there solid. On last inspection, I didn't think to climb up to see if the spindle was hollow, assuming that they were all hollow and the drawbar was missing also leaving me to guess whether it's a MT2 or B&S7 taper. Any ideas?

Since I have very little headspace in my basement, less than 7', this little mill will fit perfect. I contacted both H&W Machinery and CE Wood Machinery and inquired about value and based on their recommendations, the owner and I have agreed to a price of $500 for the mill and large vise already attached. What is everyone's thoughts on that?

Thanks