Hi guys, I am new to this machining and I have acquired this Emco compact 8 with mill attachment with missing pieces like the fine feed and change gears.

As arrived.

Now unpacked and on our modified reinforced desk in basement.

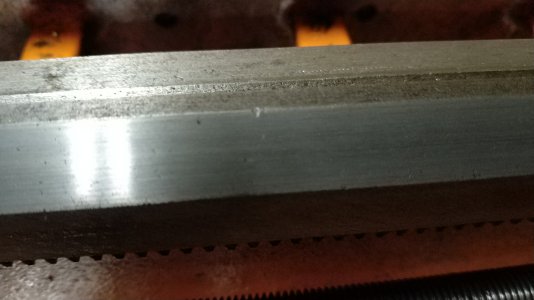

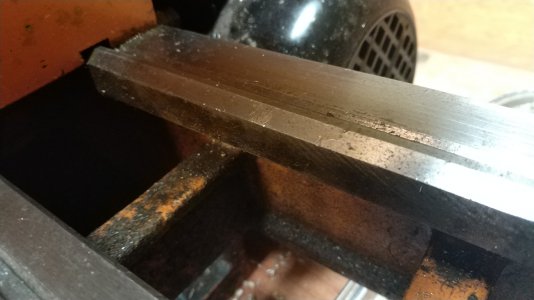

My first newbie machine to get know the lathe ( it was unanchored during this first machining thus poor quality )

Our desk

Now, I just don't want deal with shims. So I want to find where I can buy a multifix in Canada ?

And I don't know what's special about the DIN 8606 for this lathe and I heard from mikey talking about this standard being serious.

The next step is cut some plywood to slightly raise the lathe above the desk and anchor it, to avoid busting my left hand rapidly turning the carriage.

The missing change gears might not stop me at doing electronic lead screw for it.

As arrived.

Now unpacked and on our modified reinforced desk in basement.

My first newbie machine to get know the lathe ( it was unanchored during this first machining thus poor quality )

Our desk

Now, I just don't want deal with shims. So I want to find where I can buy a multifix in Canada ?

And I don't know what's special about the DIN 8606 for this lathe and I heard from mikey talking about this standard being serious.

The next step is cut some plywood to slightly raise the lathe above the desk and anchor it, to avoid busting my left hand rapidly turning the carriage.

The missing change gears might not stop me at doing electronic lead screw for it.