- Joined

- Jan 5, 2014

- Messages

- 952

The more pics of the PM-1660TL I see, the more I think that the G0509G must be a very close cousin. The head stock gears look pretty close to the same. I have a slow leak in the headstock but maybe a quarter inch over a couple of years. I keep an eye on it.

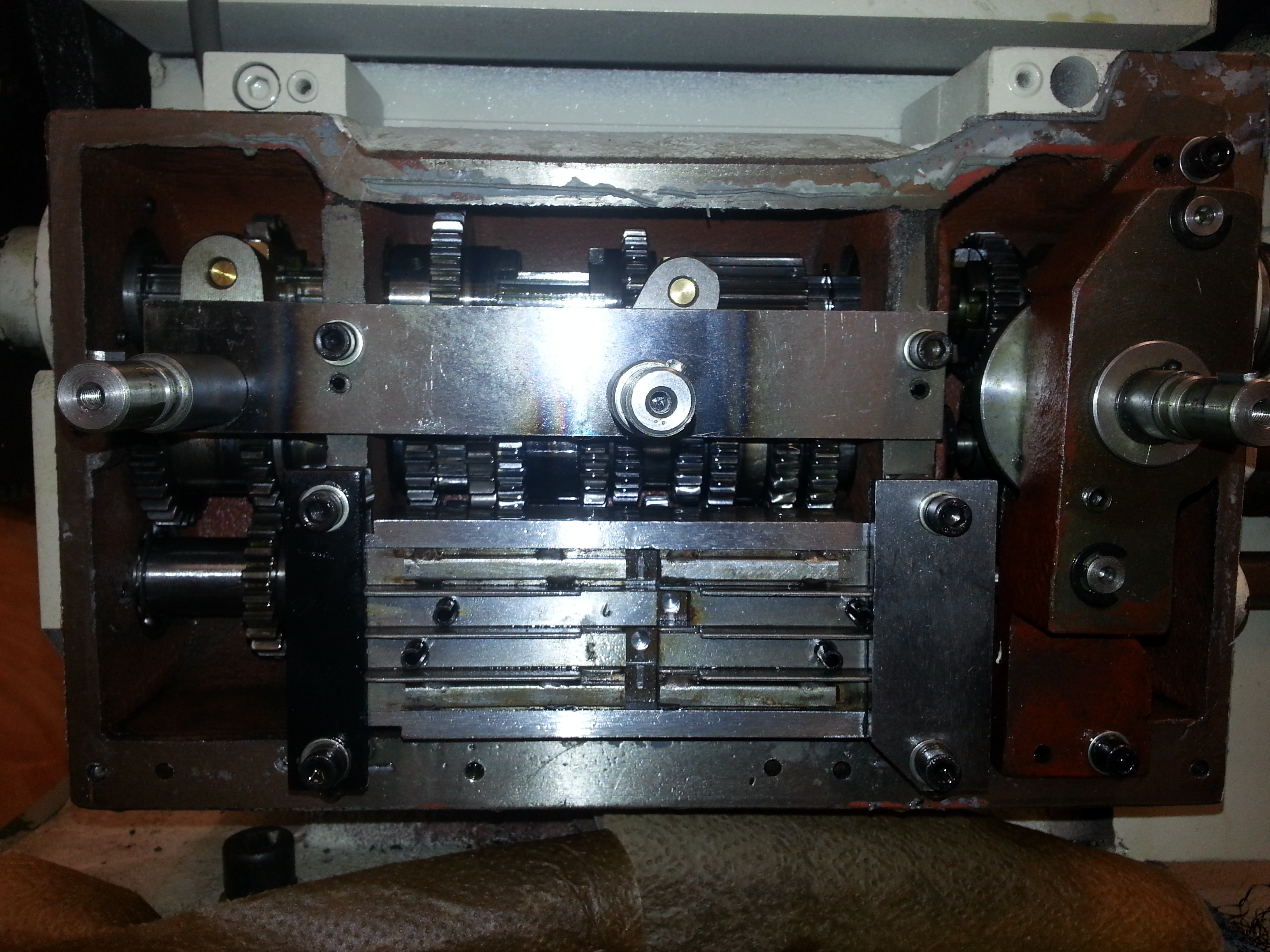

I had a sticking lead screw gearbox when I first got mine. Was just a burr on a bronze positioning fork and easy to fix. I took the transmission cover off. Here is a picture. Probably not too different than what is on yours. The gear boxes are very nice. I was impressed with the gear quality in both the headstock and the transmission.

I had a sticking lead screw gearbox when I first got mine. Was just a burr on a bronze positioning fork and easy to fix. I took the transmission cover off. Here is a picture. Probably not too different than what is on yours. The gear boxes are very nice. I was impressed with the gear quality in both the headstock and the transmission.