- Joined

- Dec 3, 2017

- Messages

- 1,911

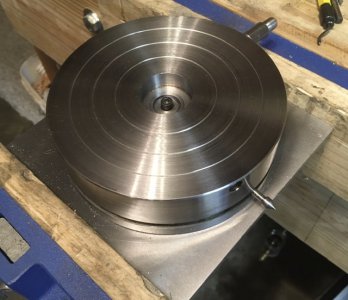

Next project that's been following me around for years is this rotary table, based off of Harold Halls design. The main body of it was made from a very large chunk of what I think is D2. It was miserable to machine. Burnt up a half dozen HSS edges before I went to carbide. At any rate, when I got just about to what you're looking at, I messed something up and stuck all this in a drawer.

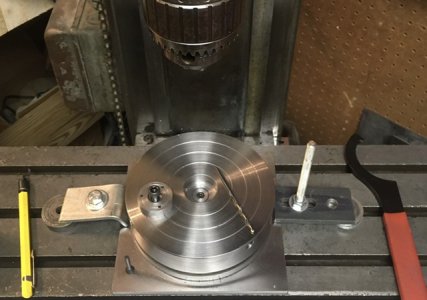

I decided today, that it's waited long enough. So after some studying of the drawings, and watching the YouTube video, and searching for the book I got the plans from, I realized that I also missed a three hole pattern in the center of the table itself. So it's set up in the mill ready for me to fix the first overlooked mistake I made all those years ago.

My plan is to drill and tap three or four holes in this to bolt an aluminum plate with a grid of threaded holes in it. I say three or four holes, because I expect this metal to be completely disagreeable. I should mention that Mr. Hall warned against using unknown metals while learning to machine. And so, this is my just desserts.

I decided today, that it's waited long enough. So after some studying of the drawings, and watching the YouTube video, and searching for the book I got the plans from, I realized that I also missed a three hole pattern in the center of the table itself. So it's set up in the mill ready for me to fix the first overlooked mistake I made all those years ago.

My plan is to drill and tap three or four holes in this to bolt an aluminum plate with a grid of threaded holes in it. I say three or four holes, because I expect this metal to be completely disagreeable. I should mention that Mr. Hall warned against using unknown metals while learning to machine. And so, this is my just desserts.