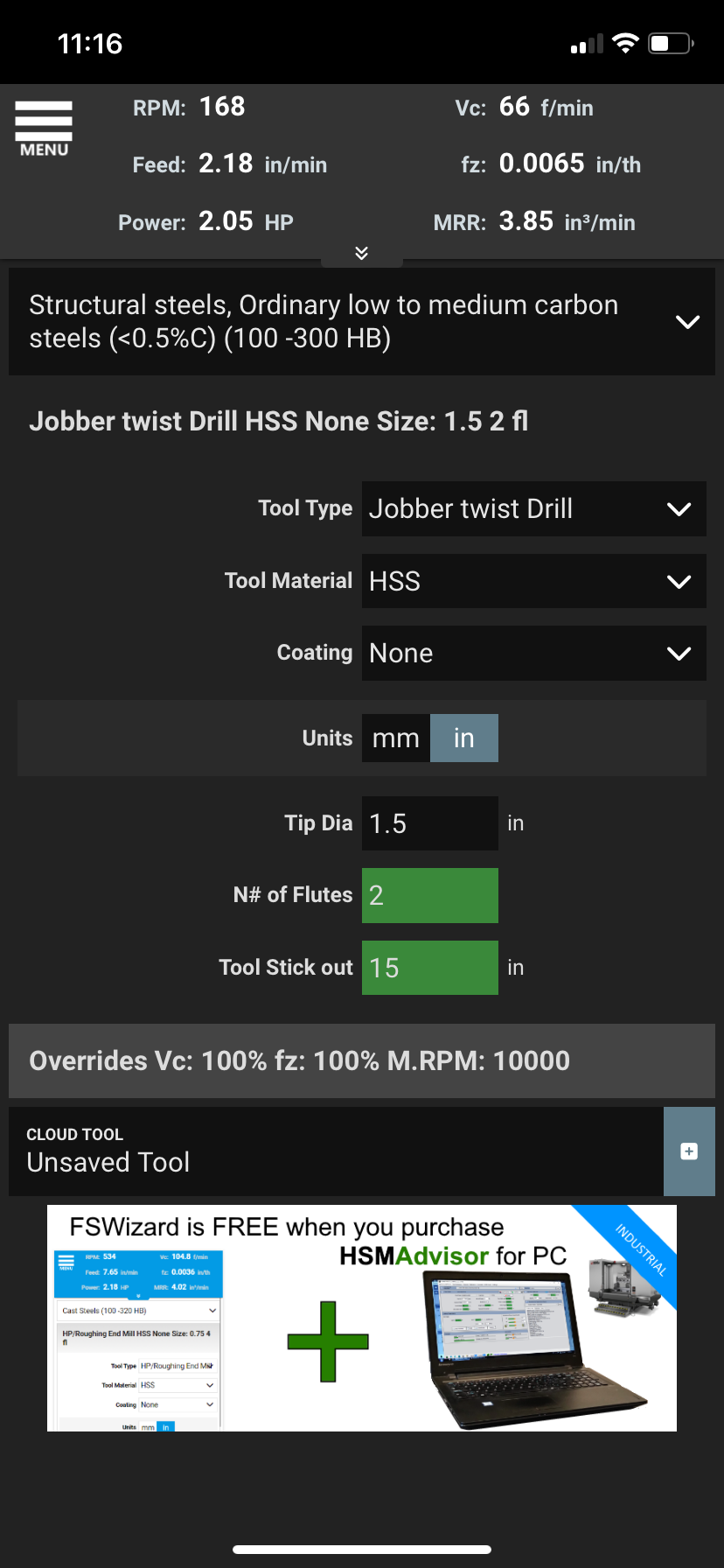

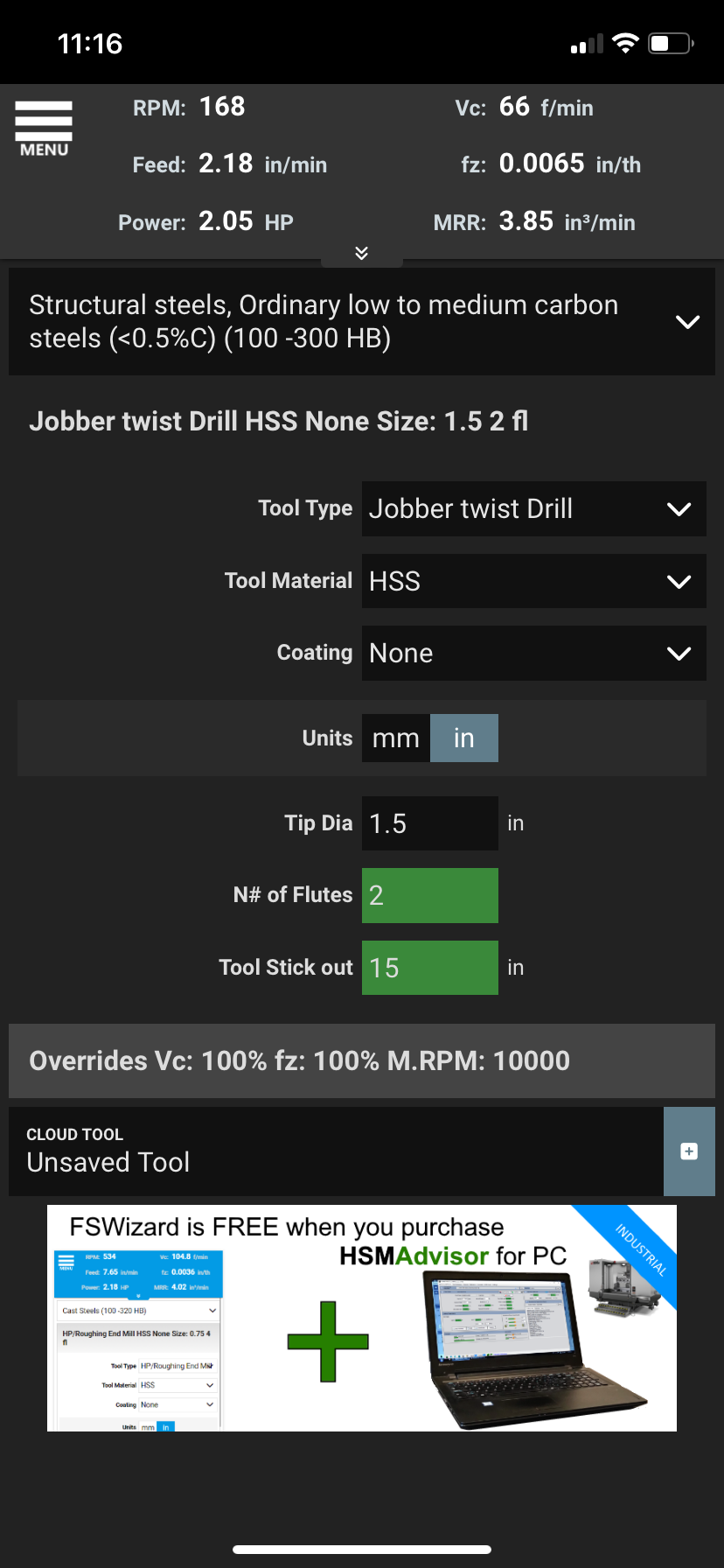

I'll learn the limits once I give it a try. First I've got to get parts and bearings.Personally, I think the 144 RPM speed you've said will be your lowest speed is too fast for drills this size. I have drilled 1.5" holes with my BP mill and run at 60 RPM which seems to be about right. This is also the approximate speed I use when drilling a hole that large in my lathe.

Just my two cents.

Ted

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Odd mill/drill heirloom

- Thread starter Batmanacw

- Start date

- Joined

- Apr 30, 2015

- Messages

- 11,318

It's old for sure- I wonder if it's some kind of a kit, maybe ordered from England?

Seems like I saw something like that on Lathes.co.uk

Seems like I saw something like that on Lathes.co.uk

- Joined

- Jun 7, 2013

- Messages

- 10,089

A 2" drill cutting mild steel about 200 RPM would be the max.

I figured out why the table was so hard to raise and fixed it. Now it goes up a touch harder than going down. I may install a counterweight to lighten the very heavy table.

I'm ordering the new step pulley tomorrow. Once I have it in hand I'll plan out the intermediate pulley shaft. New bearings are already on the way.

I'll be reusing two original pulleys that I'll modify so they are properly keyed. After the modifications done to them it will take some creative engineering.

I tried to disassemble the chuck like a Jacobs and it didn't budge. I have no idea if it's serviceable. The taper is MT3.

Tomorrow is clean up day for all the stuff that came with it. That will be interesting. Lol.

I'm ordering the new step pulley tomorrow. Once I have it in hand I'll plan out the intermediate pulley shaft. New bearings are already on the way.

I'll be reusing two original pulleys that I'll modify so they are properly keyed. After the modifications done to them it will take some creative engineering.

I tried to disassemble the chuck like a Jacobs and it didn't budge. I have no idea if it's serviceable. The taper is MT3.

Tomorrow is clean up day for all the stuff that came with it. That will be interesting. Lol.

- Joined

- Oct 17, 2018

- Messages

- 922

I intend to use this machine as a fairly heavy drill press. How slow is slow enough to run big drill bits in steel. Let's say up to 1.5" or 2"?

If I do what I'm considering right now I'll get down to 144 rpm but only up to 935 top speed. The pulley reduction will be pretty insane. I'm thinking that will be right in line with larger drills, running annular cutters, and possibly the occasional boring head.

According to my cutting speed chart, the speed for using a 2" diameter cutter in low carbon steel is 152 RPM, so it looks like you are good to go. I'd imagine you'd cut several pilot holes bigger and bigger and use a boring head or a big-ass 2" drill bit (I've never seen one that big) for the final pass.

If I do what I'm considering right now I'll get down to 144 rpm but only up to 935 top speed. The pulley reduction will be pretty insane. I'm thinking that will be right in line with larger drills, running annular cutters, and possibly the occasional boring head.

According to my cutting speed chart, the speed for using a 2" diameter cutter in low carbon steel is 152 RPM, so it looks like you are good to go. I'd imagine you'd cut several pilot holes bigger and bigger and use a boring head or a big-ass 2" drill bit (I've never seen one that big) for the final pass.

- Joined

- Sep 3, 2023

- Messages

- 220

You may be drill 1-1/2” holes in steel at your 155 RPMs. You probably will not be able to push the drill hard, but it should be doable.

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

If the material is under 2" thick I'd use an annular cutter for 2" diameter. Still need the slow rpm.I intend to use this machine as a fairly heavy drill press. How slow is slow enough to run big drill bits in steel. Let's say up to 1.5" or 2"?

If I do what I'm considering right now I'll get down to 144 rpm but only up to 935 top speed. The pulley reduction will be pretty insane. I'm thinking that will be right in line with larger drills, running annular cutters, and possibly the occasional boring head.

According to my cutting speed chart, the speed for using a 2" diameter cutter in low carbon steel is 152 RPM, so it looks like you are good to go. I'd imagine you'd cut several pilot holes bigger and bigger and use a boring head or a big-ass 2" drill bit (I've never seen one that big) for the final pass.

For bigger holes I find pilot drilling close to the web width makes going straight to the full diameter pretty easy. Last time I drilled 1.5" I step drilled a couple sizes.

- Joined

- May 7, 2023

- Messages

- 1,347

This.Personally, I think the 144 RPM speed you've said will be your lowest speed is too fast for drills this size. I have drilled 1.5" holes with my BP mill and run at 60 RPM which seems to be about right. This is also the approximate speed I use when drilling a hole that large in my lathe.

Just my two cents.

Ted

What you can get away with and what you can do on a regular basis are two different things.

Our 18" clausing drill press at work struggles with drills over 1.25" if they aren't sharpened properly.

To OPs question, I would rather have the ability to go slower than faster for a ballpark recommendation.

It has a number 3 morse taper. It resembles a standard drill press spindle, just built into a heavier housing. It does not have a slot for a wedge. It has a hole for a drawbar but no evidence it ever had a drawbar. A rod through the top knocks out the tapers.SO what's the spindle ? Does it have a taper or is the chuck threaded on ? Another question , how do ya like that China drill sharpener on the bench behind the drill press ?

animal

The drill sharpener is really nice. It doesn't make perfect looking bits but it does make drill points that work extremely well. It was expensive but I'd buy it again. It goes up to 20mm.