Hi all, hoping for a miracle...

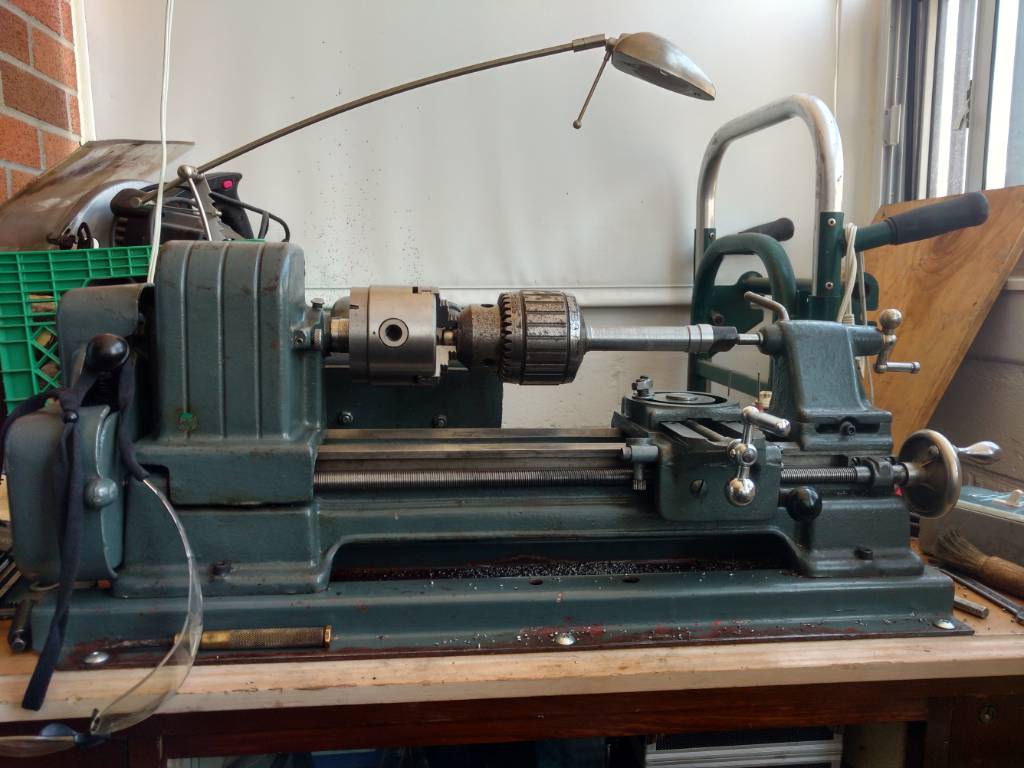

Yesterday I broke my lathe, I stripped the half nuts while taking a heavy cut on my craftsman 109. Yes entirely my fault! And I am suitably pi$$ed at myself!!!!

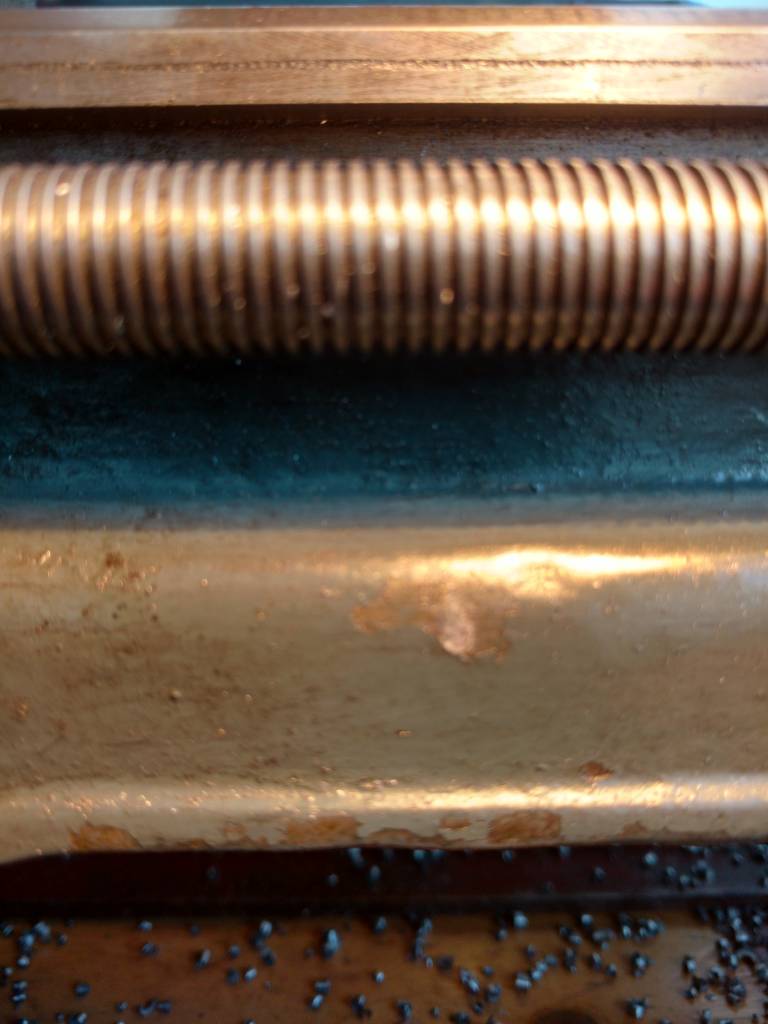

I want to make a new halfnut assembly but this lathe has a weird leadscew. It's 1/2"-16 acme thread. I've scoured the web for a nut this size, then for a tap, but no success. I managed to find a 1/2"-16 tap but it's not acme.

Question 1: if I make a new nut with this standard tap will it work or screw up my leadscrew?

Thanks in advance.

Many more questions to follow I'm sure. I'm relatively new at this.

Yesterday I broke my lathe, I stripped the half nuts while taking a heavy cut on my craftsman 109. Yes entirely my fault! And I am suitably pi$$ed at myself!!!!

I want to make a new halfnut assembly but this lathe has a weird leadscew. It's 1/2"-16 acme thread. I've scoured the web for a nut this size, then for a tap, but no success. I managed to find a 1/2"-16 tap but it's not acme.

Question 1: if I make a new nut with this standard tap will it work or screw up my leadscrew?

Thanks in advance.

Many more questions to follow I'm sure. I'm relatively new at this.