- Joined

- Oct 17, 2023

- Messages

- 10

Hello All,

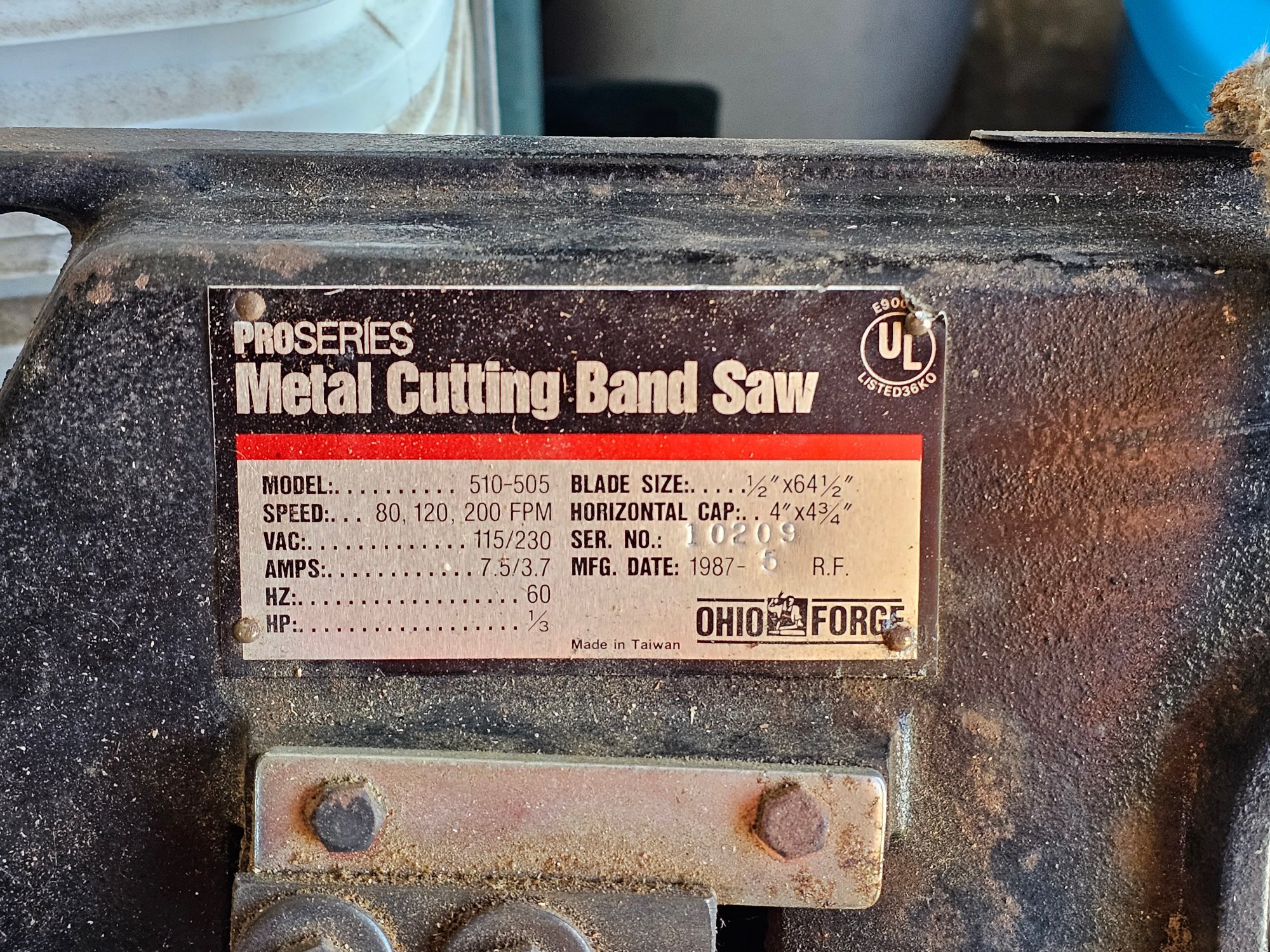

I recently got my hands on a Ohio Forge Horizontal Band Saw Model 510-505 for the perfect price of Free. It does need a little maintenance a lot of it is pretty self explanatory, but I have some questions that I'm hoping you might be able to help me with.

1st off it didn't come with an owners manual. Doe anybody know where I might be able to find one? I did try the link to the free Bandsaw manuals but there was no luck.

2nd It looks like the Bearings are serviceable but one of mine looks to be a little damaged and may need to be replaced. Are their replacements available? is there a site that you could recommend to find them.

3rd I've seen several variants with different Branding and minor differences here & there like different sized motors. or the legs having s slightly different design but all off the variants seem to have a pin that locks the saw in the down position for transporting. Does the ohio forge have something like this? I've looked in all the places that the variants have theirs but I don't see a Pin hole anywhere.

I recently got my hands on a Ohio Forge Horizontal Band Saw Model 510-505 for the perfect price of Free. It does need a little maintenance a lot of it is pretty self explanatory, but I have some questions that I'm hoping you might be able to help me with.

1st off it didn't come with an owners manual. Doe anybody know where I might be able to find one? I did try the link to the free Bandsaw manuals but there was no luck.

2nd It looks like the Bearings are serviceable but one of mine looks to be a little damaged and may need to be replaced. Are their replacements available? is there a site that you could recommend to find them.

3rd I've seen several variants with different Branding and minor differences here & there like different sized motors. or the legs having s slightly different design but all off the variants seem to have a pin that locks the saw in the down position for transporting. Does the ohio forge have something like this? I've looked in all the places that the variants have theirs but I don't see a Pin hole anywhere.