- Joined

- Oct 9, 2013

- Messages

- 26

Damico,

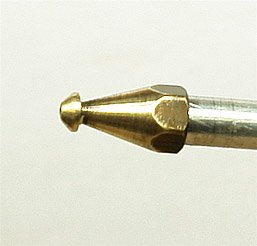

On the QCGB, if I were you I would replace the spring loaded ball type oilers with the straight cup type, which Atlas did a few years after yours was built. They look like the spindle oil cups only smaller. You can I think get them from Clausing. You can also get them from McMaster. You may not be able to do this on the two on the carriage. There is a specific oil can tip made to work with these and also with the cups. I have a photo somewhere.

Robert D.