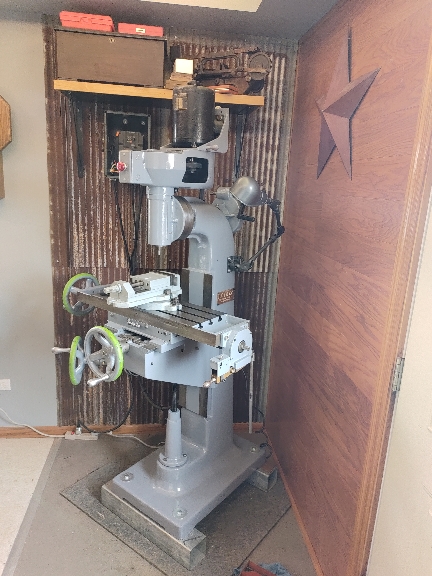

Picked this up recently. Seems in good condition from what I can tell so far. I was told it came out of the Dodge factory in Detroit. Apparently was sold in the early 1980s, painted black and sat in a garage before I acquired it. Everything was painted black even the top of the table. That may have helped as there isn't much rust. There is 3 heavy coats of paint on it. Looks like it was safety yellow once and originally green? Motor and controls look to be done in the 1960s.

I have been wanting a small vertical mill for awhile and this is perfect in size, etc. for my needs.

Not exactly sure on the model. Not a 40 as it doesn't have quill feed, etc. I have seen one other similar online. Otherwise it is close to a model 40.

Going to pull the table and check the ways tomorrow. Then it will wait until I have more time in the winter to freshen it all up. Thinking I will get VFDs for both motors? I like the ability to control speeds. I know the old motors are not inverter duty but I've done it before and those motors are still running.

Sent from my Nokia 8 V 5G UW using Tapatalk

I have been wanting a small vertical mill for awhile and this is perfect in size, etc. for my needs.

Not exactly sure on the model. Not a 40 as it doesn't have quill feed, etc. I have seen one other similar online. Otherwise it is close to a model 40.

Going to pull the table and check the ways tomorrow. Then it will wait until I have more time in the winter to freshen it all up. Thinking I will get VFDs for both motors? I like the ability to control speeds. I know the old motors are not inverter duty but I've done it before and those motors are still running.

Sent from my Nokia 8 V 5G UW using Tapatalk