- Joined

- Jan 31, 2016

- Messages

- 11,448

Rummaging thru the stuff cleaning up and found some older pics . Pre 1999 , so OK to post . I'm going to keep these at hand as they might just come in handy next week for a few interviews .  Anyway , these were some very noteworthy projects over the early years of the career . Lets see some of your cooler projects !

Anyway , these were some very noteworthy projects over the early years of the career . Lets see some of your cooler projects !

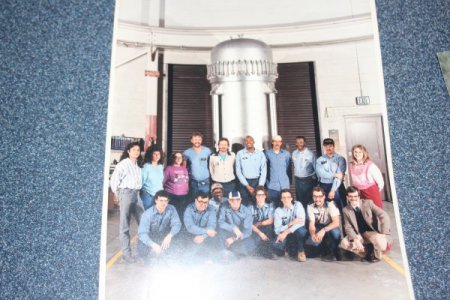

Solid Inconel filter housing . 9 month project . Machining was performed on that big Makino spoken of in the past . The shell and heads were no problems , the D ring plates and spider plates which are internal were brutal . 4" insert drills hammering thru 1.5" Inconel plate and then circle milling to size was quite a task . One expensive unit .

One of our big bore projects . 120mm if I remember correctly . The shells were a piece of cake . The fuse work was not . More darn threads and electronics packed into such a small cone !

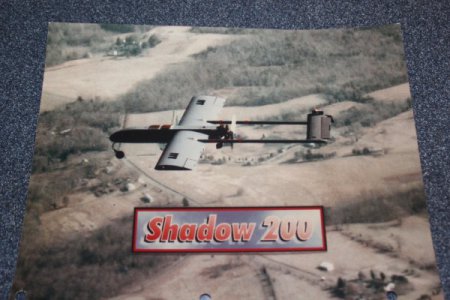

UAVs . Started with Win Barr towing a " flying saucer shaped thing " up I 83 on a trailer . Progressed into Pioneer and Shadow programs for all branches of the military . Built from scratch , ground up . Fixtures , motors , molds , tooling etc . The gimble which is hard to see in the pic started out as a 250lb chunk of 15-5 stainless HT to 32RC . Holding the FLIR camera with so called " frictionless bearings " . Ended up at 8 lbs when complete . Had to make this part in a manual lathe because the cncs couldn't take the cuts or the angles needed to satisfy engineering specs . Grooving 5" deep ( 10 on diameter ) , contouring radiuss , turning tapers 5" deep in 2 inch grooves used to be fun ! All finish angles on ODs and faces and Ids were finished on Makino cnc slant bed . One of my favorite jobs I think . All bores within .0002 , all the GDT things , indicating thru the bores holding TIRs , etc . All bearings ,electronics , wiring were installed and into the the composite shop for the carbon fiber shell . I'm sure these drones are still in production with well over 2 million hours of flight time . Go figure , I can buy a drone from Amazon for $29.99 shipped nowadays !

The coolest thing about doing the work behind closed doors is being able to sub some out to the smaller job shops . The prints always go out as " brackets " , and that shop will never actually know the finished product as they are machined to NNS . Near net shape . So , just some cool stuff to know .

I'm the good looking blue collar guy in the pics …………………………..unfortunately years ago .

Lets see some more pics !

Solid Inconel filter housing . 9 month project . Machining was performed on that big Makino spoken of in the past . The shell and heads were no problems , the D ring plates and spider plates which are internal were brutal . 4" insert drills hammering thru 1.5" Inconel plate and then circle milling to size was quite a task . One expensive unit .

One of our big bore projects . 120mm if I remember correctly . The shells were a piece of cake . The fuse work was not . More darn threads and electronics packed into such a small cone !

UAVs . Started with Win Barr towing a " flying saucer shaped thing " up I 83 on a trailer . Progressed into Pioneer and Shadow programs for all branches of the military . Built from scratch , ground up . Fixtures , motors , molds , tooling etc . The gimble which is hard to see in the pic started out as a 250lb chunk of 15-5 stainless HT to 32RC . Holding the FLIR camera with so called " frictionless bearings " . Ended up at 8 lbs when complete . Had to make this part in a manual lathe because the cncs couldn't take the cuts or the angles needed to satisfy engineering specs . Grooving 5" deep ( 10 on diameter ) , contouring radiuss , turning tapers 5" deep in 2 inch grooves used to be fun ! All finish angles on ODs and faces and Ids were finished on Makino cnc slant bed . One of my favorite jobs I think . All bores within .0002 , all the GDT things , indicating thru the bores holding TIRs , etc . All bearings ,electronics , wiring were installed and into the the composite shop for the carbon fiber shell . I'm sure these drones are still in production with well over 2 million hours of flight time . Go figure , I can buy a drone from Amazon for $29.99 shipped nowadays !

The coolest thing about doing the work behind closed doors is being able to sub some out to the smaller job shops . The prints always go out as " brackets " , and that shop will never actually know the finished product as they are machined to NNS . Near net shape . So , just some cool stuff to know .

I'm the good looking blue collar guy in the pics …………………………..unfortunately years ago .

Lets see some more pics !

Last edited: