- Joined

- Jul 9, 2019

- Messages

- 70

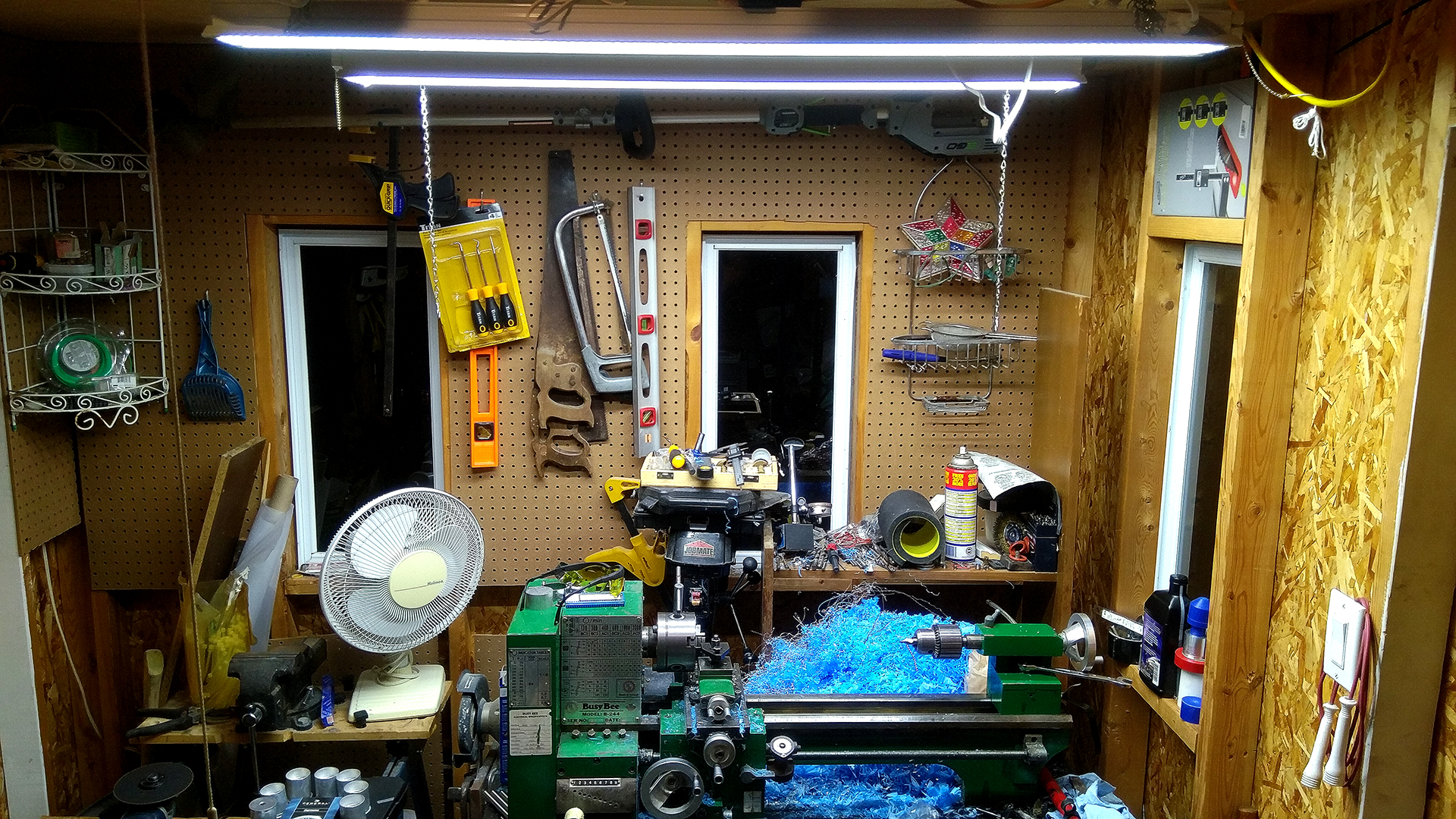

I was doing a massive production run today and was running her for about 10 hours straight then it started to do weird things. It dropped from full speed down to 1/3 speed, drew way more current (dimmed the lights in my shed) for a few seconds to a minute and then went back to full speed, did that over and over, didn't seem to make any different noises, no smells. Even at full speed the amount of torque/power was way way down from what it normally is. After I finished a few more parts with it running like this (about 10 minutes) it permanently dropped to 1/3 speed or less with almost no torque.

When I went to pull the cover off the back of the motor I noticed the air intake screen was plugged up with delrin shavings, so I might have overheated it. I let it sit for a few hours then fired it up again but only 1/3 speed or less, lots of current draw, no torque. I couldn't get the motor cover off because one of the screws to the cover is on the very bottom and I'll have to unbolt the lathe from the bench to get at it. A project for tomorrow maybe.

If I rotate the chuck by hand I can hear some scratching noises in the motor, it was always silent before, but the chuck/motor rotates easily by hand.

Any suggestions on what to look at/for?

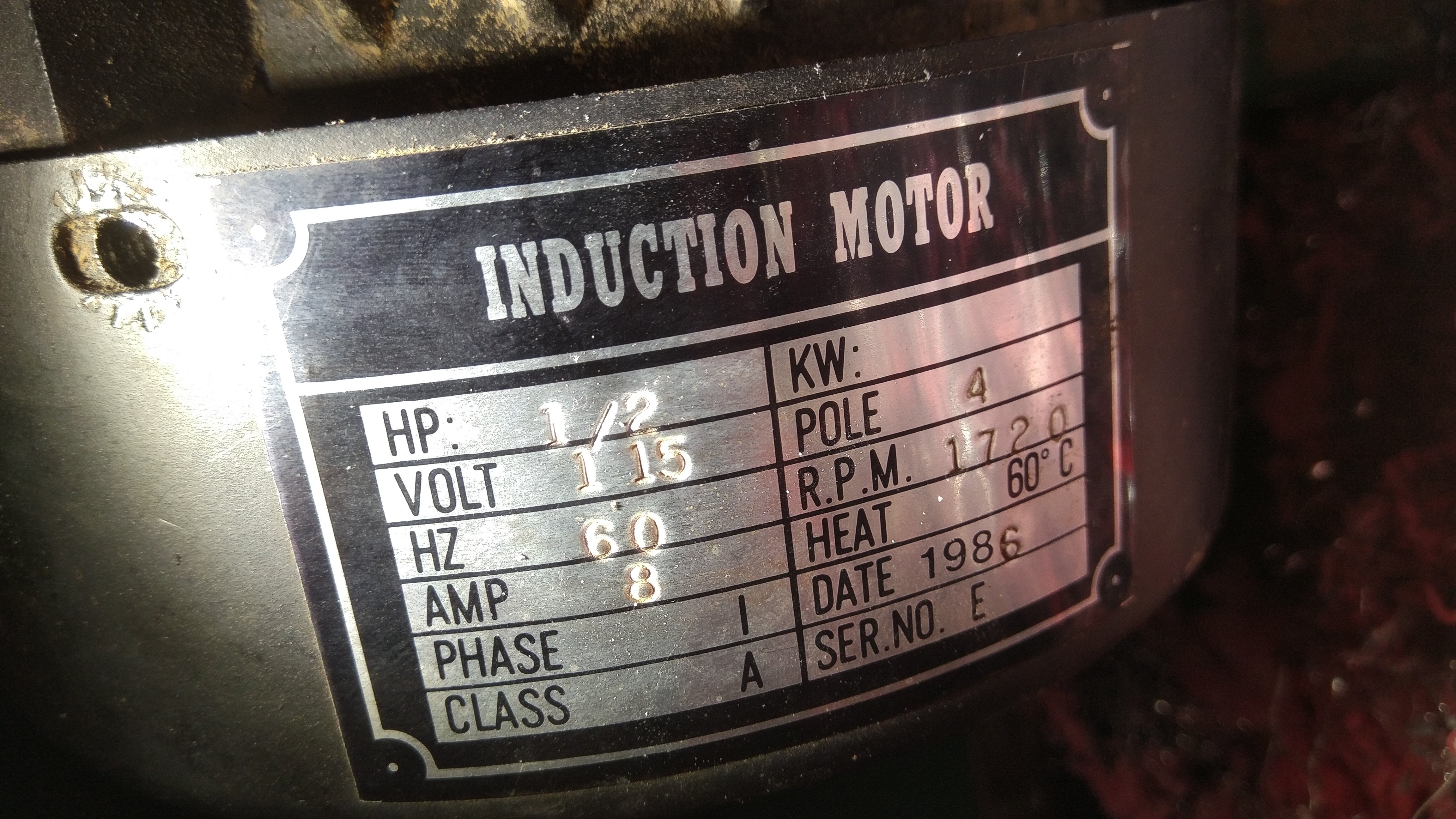

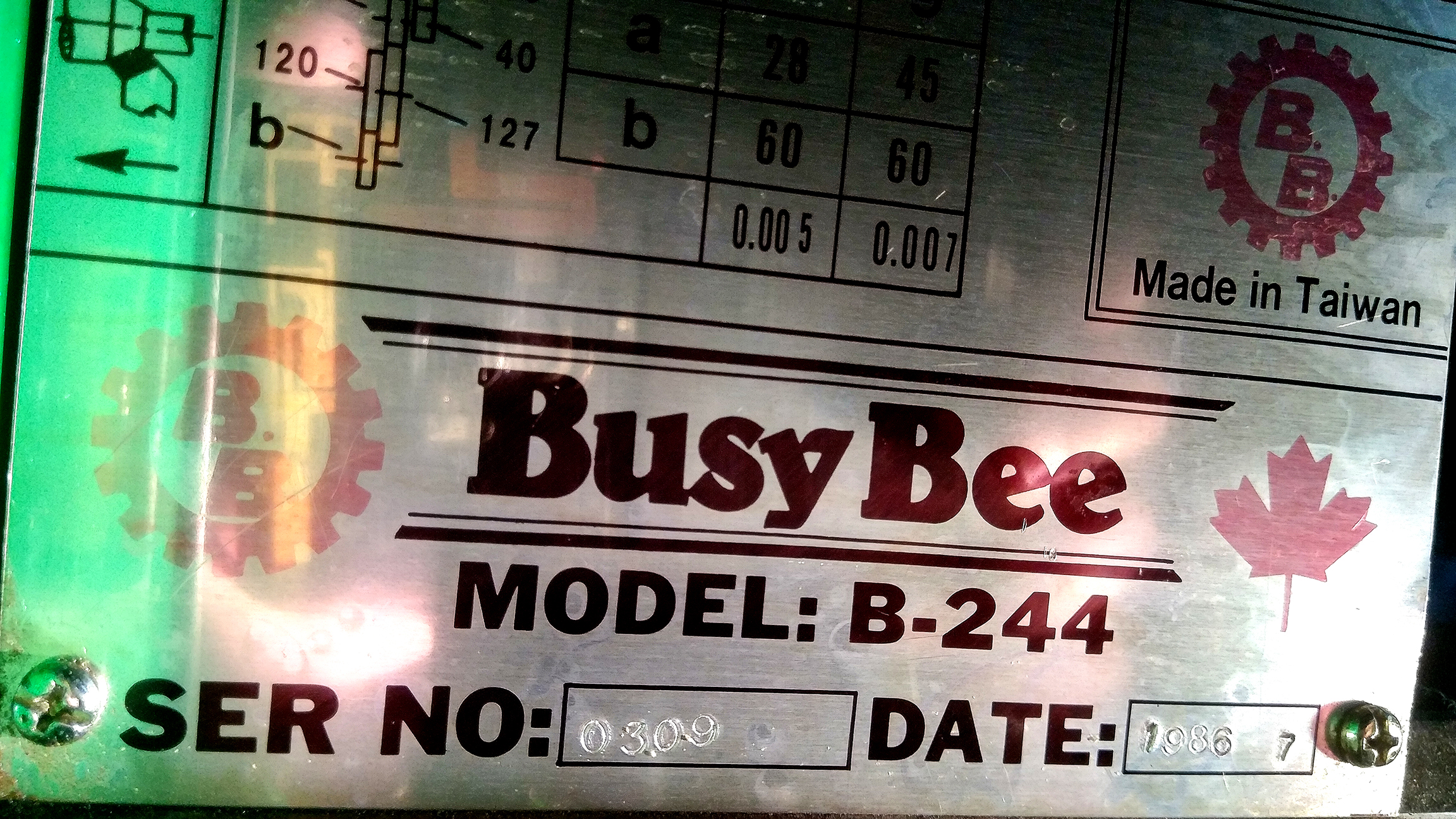

If the motor is cooked I'd like to put a motor on it that I can control the speed of (i.e. run it slow but still have full torque). Currently I only have 120v/60hz/20amp available in my shed but I could run 240v to it if necessary. No idea where to start with that stuff though (controller/motor), suggestions appreciated and if you need more info/measurements from the lathe just let me know.

Luckily I was able to finish the production run I was doing so it's not a panic that it get fixed quick.

Thank you for any help you can provide.

-Jamie M.

When I went to pull the cover off the back of the motor I noticed the air intake screen was plugged up with delrin shavings, so I might have overheated it. I let it sit for a few hours then fired it up again but only 1/3 speed or less, lots of current draw, no torque. I couldn't get the motor cover off because one of the screws to the cover is on the very bottom and I'll have to unbolt the lathe from the bench to get at it. A project for tomorrow maybe.

If I rotate the chuck by hand I can hear some scratching noises in the motor, it was always silent before, but the chuck/motor rotates easily by hand.

Any suggestions on what to look at/for?

If the motor is cooked I'd like to put a motor on it that I can control the speed of (i.e. run it slow but still have full torque). Currently I only have 120v/60hz/20amp available in my shed but I could run 240v to it if necessary. No idea where to start with that stuff though (controller/motor), suggestions appreciated and if you need more info/measurements from the lathe just let me know.

Luckily I was able to finish the production run I was doing so it's not a panic that it get fixed quick.

Thank you for any help you can provide.

-Jamie M.