- Joined

- May 7, 2020

- Messages

- 263

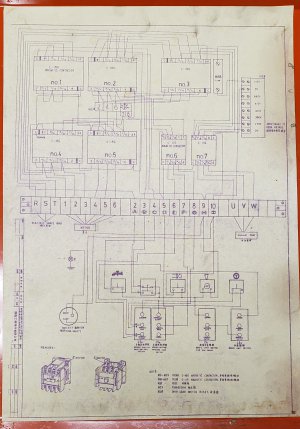

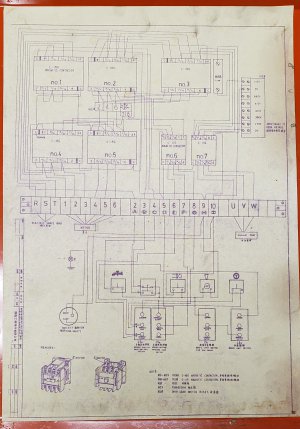

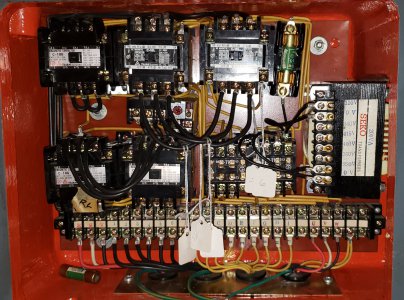

Electrical diagrams don't usually survive a commercial environment. This one is pristine and I'm including it here for the 7.5hp 2-speed 1740G.

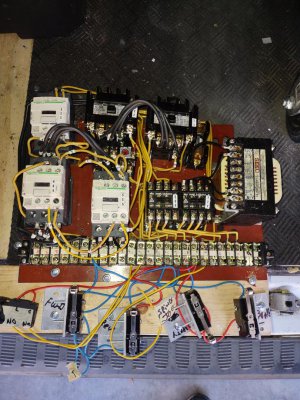

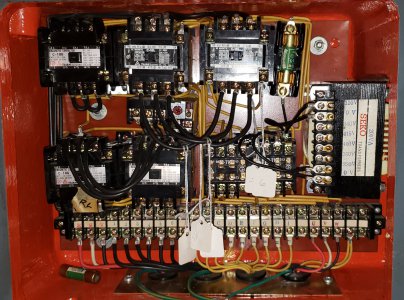

Here is a nicely preserved electrical panel per the above:

Note for those installing a Rotary Phase Converter and if your diagram looks like the above:

Wiring RPC to Lathe Input:

T1-Black -> L1-Red (R)

T2-Red -> L2- White (S)

T3-White/Blue -> L3-Black (T) Manufactured Leg

Here is a nicely preserved electrical panel per the above:

Note for those installing a Rotary Phase Converter and if your diagram looks like the above:

Wiring RPC to Lathe Input:

T1-Black -> L1-Red (R)

T2-Red -> L2- White (S)

T3-White/Blue -> L3-Black (T) Manufactured Leg

Last edited:

![IMG_20210915_121750394[1].jpg](/data/attachments/336/336253-06b01120b985c47074a8d08fa19a5bdc.jpg)

![IMG_20210915_115526767[1].jpg](/data/attachments/336/336254-effbca982e0ce066bd4df1db0c5cd6f4.jpg)