- Joined

- Feb 13, 2018

- Messages

- 179

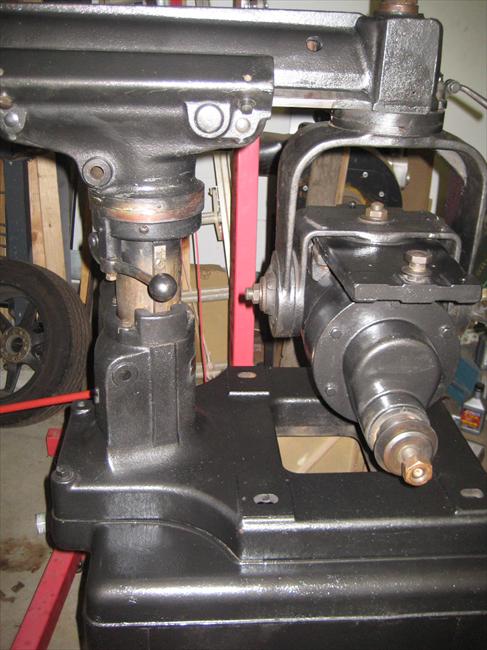

Been all pretty much covered here, but if one has the room for it, nothing is more versatile than a quality RAS. Nothing is more frustrating than the later cheaper Sears/Montgomery Ward models. As mentioned, the earlier Craftsman models are capable of better work than most hacks using them. I've used one for going on fifty years now and if used with care and common sense, it's an excellent machine.

Kids, don't try this at home. I was building a 4x4-framed garden house for my wife and would be needing to cut many timbers. The 10" blade wouldn't make the cuts, so I removed the guard and bought a 12" blade. With the workpiece firmly clamped to the table fence and resting on an extension roller, THINK, FOCUS, saw on, pull it through, back, saw off.

After getting over the original fear of pulling that unguarded 12" blade toward my nose, I came to realize it was actually a safer operation than trying to cross-cur or miter a long 4x4 on a table saw.

jack vines

Kids, don't try this at home. I was building a 4x4-framed garden house for my wife and would be needing to cut many timbers. The 10" blade wouldn't make the cuts, so I removed the guard and bought a 12" blade. With the workpiece firmly clamped to the table fence and resting on an extension roller, THINK, FOCUS, saw on, pull it through, back, saw off.

After getting over the original fear of pulling that unguarded 12" blade toward my nose, I came to realize it was actually a safer operation than trying to cross-cur or miter a long 4x4 on a table saw.

jack vines