- Joined

- Jan 7, 2016

- Messages

- 3,270

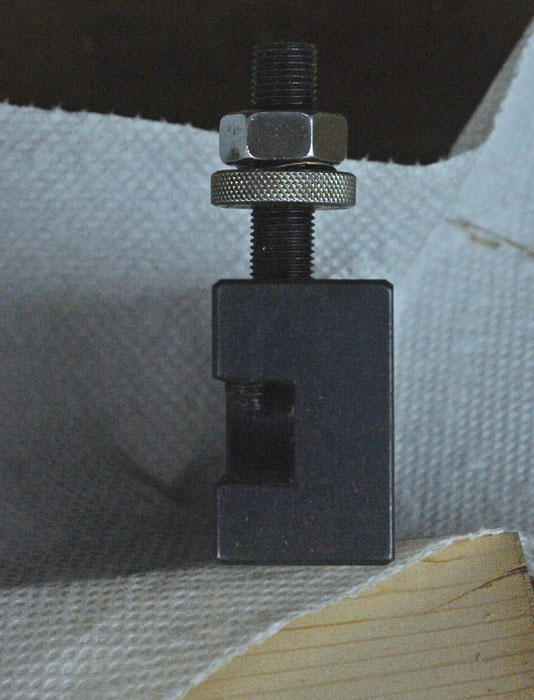

Hi guys. I have a PM1022 lathe with the "standard" chinese QCTP. I felt it had a lot of slop in the mechanism, including the round part that the handle attaches to. My brother has an older Jet lathe (40"?) with a Phase II QCTP on it. It is nice and tight with basically no slop. The Phase II that I got is absolutely no better than the craptastic Chinese one that came on the lathe from PM. The only thing that would be better about the Phase II is the center mounting bolt is much more substantial than the mounting system on the originial, but I don't need to pay $225 just for a bigger mounting bolt. It was purchased through Amazon from Travers tool. Didn't really want to spend $300+ on just a QTCP but it looks like that is what one must do to get a decent QCTP.