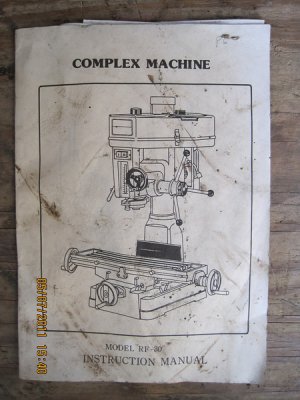

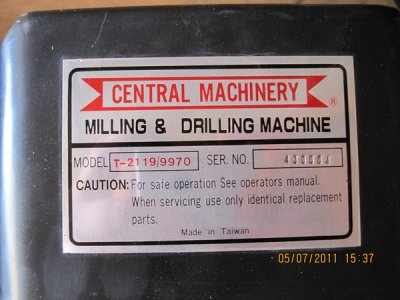

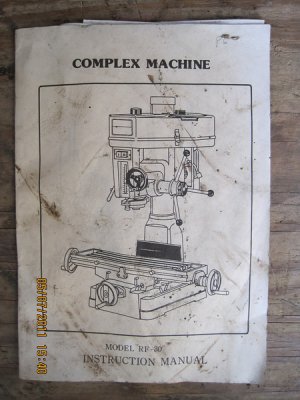

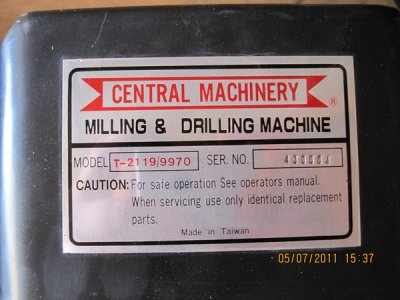

I bought this Taiwan made mill/drill today for $600. It is an older HF unit. The book calls it an RF-30, and in the docs, HF is still referred to as Harbor Freight Salvage Company. I am not sure when they changed that name, but I seem to recall it being a while ago, maybe ten years?

It came with the base and tray:

And it also came with a cheap rotary table, cheap mill vise and a set of cheap end mills.

All in all, I think it was worth the $600 I paid for it.

I picked up a large arbor press from the same guy. Cheap import, but a big one.

It came with the base and tray:

And it also came with a cheap rotary table, cheap mill vise and a set of cheap end mills.

All in all, I think it was worth the $600 I paid for it.

I picked up a large arbor press from the same guy. Cheap import, but a big one.