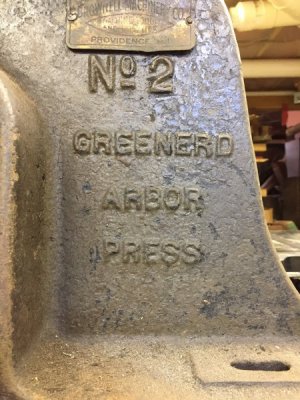

And this is the one that I left behind.

After doing more research as a result of the feedback in this thread, I almost convinced myself to try to find a #3 Greenerd, but ultimately decided against it because of cost, transport difficulty (for me) and shop space.

When I arrived to look at / pick up the #2 I found, the guy says "Oh the arbor press, you want the big one or the little one?" to which I say, "The big one??!!"

So he takes me to the big one and as soon as I see it, I realize it's a #3 on a stand! The second thing I see is that the casting is missing a big chunk and physical examination proves that while functional, the press-shaft is now quite wobbly.

The chunk of missing casting and bent handle leads me to believe that this one was abused. Ultimately, I decided not to change horses. I don't know a lot about repairing castings but this one just looks like it would be more effort and I'd end up with an arbor press with a compromised head.

Sigh.

I could go back and get it. It would probbaly work well enough for my use.

View attachment 292145

View attachment 292146