R

Robert LaLonde

Forum Guest

Register Today

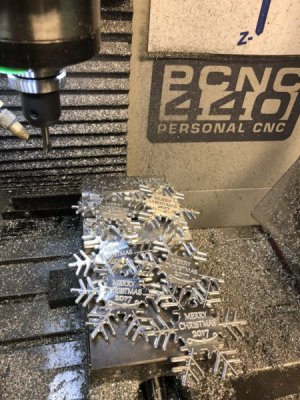

I've made a lot of similar lead molds for a buddy that makes bass jigs. The ones I make are small (1/2" to 3/4") and have slots to lay hooks and swivels that get molded into the lead. There are usually 3 or 4 jigs to each mold. I don't have any pictures of the finished products but will try to find a drawing or two from the cad drawings.

Lead casting molds is a large percentage of what I do. I have to say that is a nice basic spinnerbait or buzzbait head. I had to laugh when you said 1/2 to 3/4 was small. I do a lot of stuff in the 1/32 to 1/4 range. Most of my best work in lead casting molds is quite small. Larger stuff is usually brute force.