F

f350ca

Forum Guest

Register Today

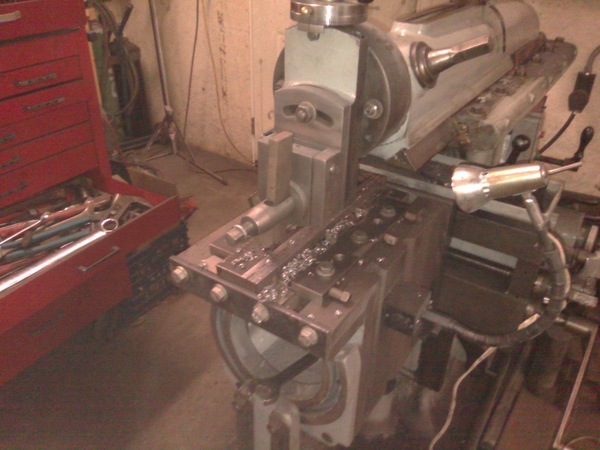

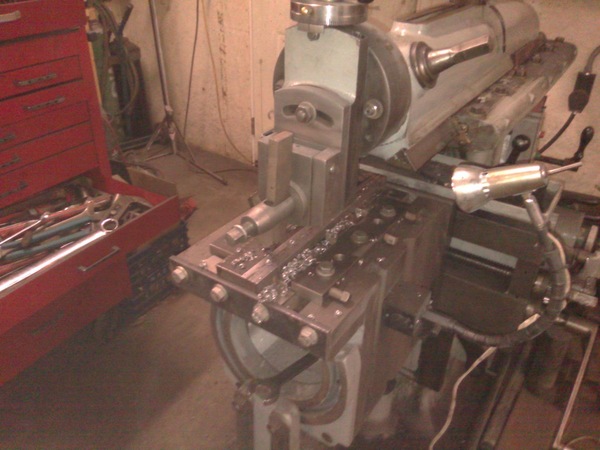

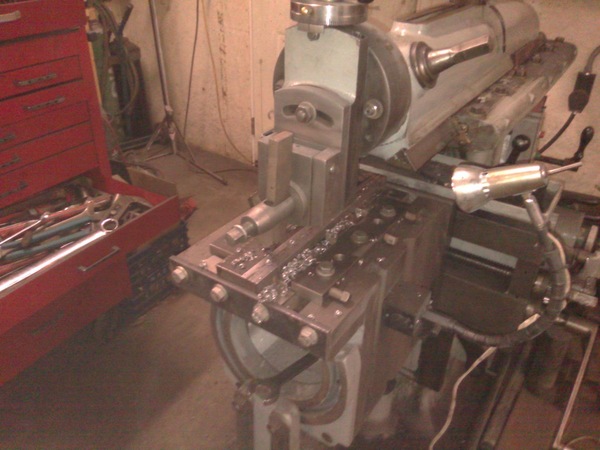

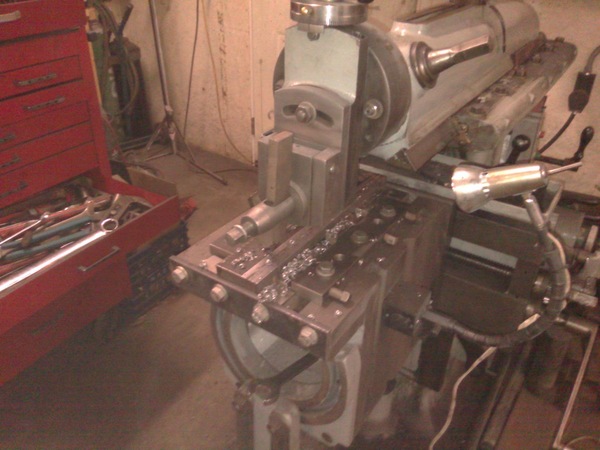

I need a better system for sharpening the thickness and jointer blades. And a project.

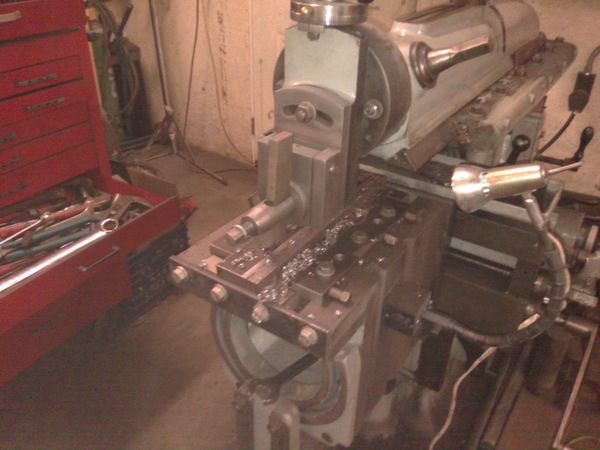

Started with the fixture that will hold the blade. In order to make that we needed to make a clamp system for the shaper.

Almost at the limit of the shaper cutting 16 inches.

Greg

Started with the fixture that will hold the blade. In order to make that we needed to make a clamp system for the shaper.

Almost at the limit of the shaper cutting 16 inches.

Greg