- Joined

- Mar 26, 2018

- Messages

- 8,407

Hey Gang,

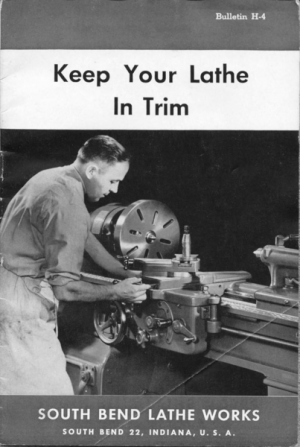

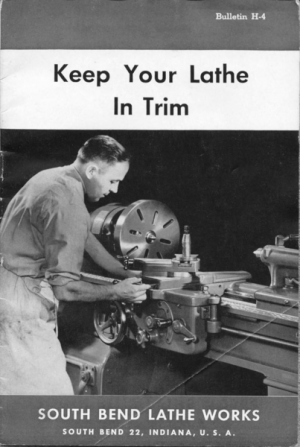

I am thinking I need to gather up a way of using the dogs that hold all types of work. I see the dogs come in different sizes. My 13" SB has the 1 7/8 spindle threads with 8 TPI. I am showing a pic of the part as it appears to have a center mounted in the spindle as well. How do I find such a piece? How is the center mounted? What do you call the plate? That is a BIG one.

Thank you for your help.

I am thinking I need to gather up a way of using the dogs that hold all types of work. I see the dogs come in different sizes. My 13" SB has the 1 7/8 spindle threads with 8 TPI. I am showing a pic of the part as it appears to have a center mounted in the spindle as well. How do I find such a piece? How is the center mounted? What do you call the plate? That is a BIG one.

Thank you for your help.