-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Playing with dollies

- Thread starter WillieP

- Start date

- Joined

- Apr 30, 2012

- Messages

- 1,138

Most of my smaller stuff is set up so I can just run a pallet jack under it. I'm going to rearrange this Spring, if it ever gets here.

- Joined

- Jan 28, 2011

- Messages

- 3,486

Walter, known as Starlight Tools, wrote up how he setup his Goshen 1440 lathe with casters that lock down to the floor. I do not know if that topic survived the hacking incident or not.

I have a set of vehicle dollies that work for moving my smaller lathe around. At work, I use a pallet jack to move stuff around. If the machine is already setup for the pallet jack, great, if not, then a lot of work using toe jacks is called for at times.

Another option, if you have a smooth floor is just a nice lever works very well.

Pierre

I have a set of vehicle dollies that work for moving my smaller lathe around. At work, I use a pallet jack to move stuff around. If the machine is already setup for the pallet jack, great, if not, then a lot of work using toe jacks is called for at times.

Another option, if you have a smooth floor is just a nice lever works very well.

Pierre

A lathe is one machine I wouldn't keep on dollies/casters. Once you square one up so it cuts correctly you realize how a few thousandths difference in height from one corner to the next really makes. In my case I need all the help I can get.

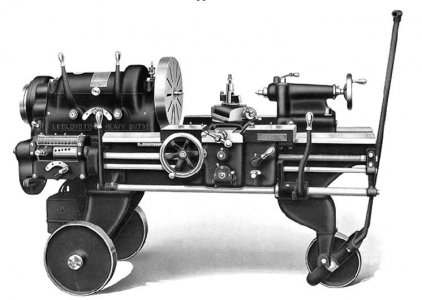

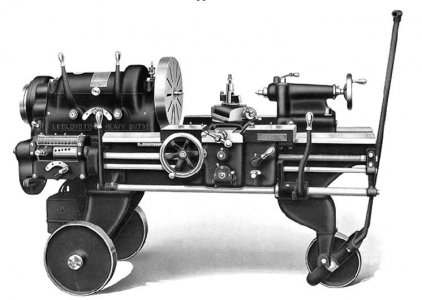

LeBlond made a rolling lathe. Note the tail end is on a single wheel. That avoids the bed twist issue.

A lathe is one machine I wouldn't keep on dollies/casters. Once you square one up so it cuts correctly you realize how a few thousandths difference in height from one corner to the next really makes. In my case I need all the help I can get.

- - - Updated - - -

I agree with the OP; I put as much of my shop on wheels as I can. I have moved stuff so often that it really makes sense.

- Joined

- Sep 22, 2010

- Messages

- 898

Walter, known as Starlight Tools, wrote up how he setup his Goshen 1440 lathe with casters that lock down to the floor. I do not know if that topic survived the hacking incident or not.

I have a set of vehicle dollies that work for moving my smaller lathe around. At work, I use a pallet jack to move stuff around. If the machine is already setup for the pallet jack, great, if not, then a lot of work using toe jacks is called for at times.

Another option, if you have a smooth floor is just a nice lever works very well.

Pierre

I use the Footmaster Castors under most of my machinery and other shop items.

http://www.footmastercasters.com/

My 14x40 Lathe, as Pierre mentioned was set up with them. http://www.hobby-machinist.com/showthread.php/844-Gosan-1440V-Metal-Lathe?highlight=footmaster It came stock with six cast iron pucks, about the size of hockey pucks, and 1/2-12 Wh levelling bolts. I used the GD-100S castors which have a M16 female thread for mounting, and took some M16 All Thread and drilled and tapped them 1/2-12 and threaded these into the castors. Then I could use the stock bolts to bolt the castors to the bottom of the lathe. Since it had six spots, I used the six castors.

I can roll the lathe around easily and once it is place, I can use the built in levelling feet to adjust the lathe so that it is 0 0 with my Starrett 98 level.

The lathe has been very stable on these castors, both when rolling and when "placed"

One added benefit was that with the lathe as it came, I had to bend over to operate it, as it was too short IMHO. Added the Footmaster castors, lifted the lathe just over 4-3/4" which put the centre height of the lathe at a much more convenient height for me.

I have also used these castors under many of my roll cab tool boxes, this way, I can level the drawers and they have a much better lock than conventional locking castors.

If the floor is really sloped, as where my 50 Ton H Frame press sits, I added a hockey puck under the levelling pad which extends the levelling range of the castor.

If I was to redo the lathe or if I was to do another lathe, I would probably go with the GD-120S castors as the internal levelling screw is much heavier than the one in the GD-100 and smaller.

Walter