- Joined

- Jun 7, 2019

- Messages

- 151

Hey guys,

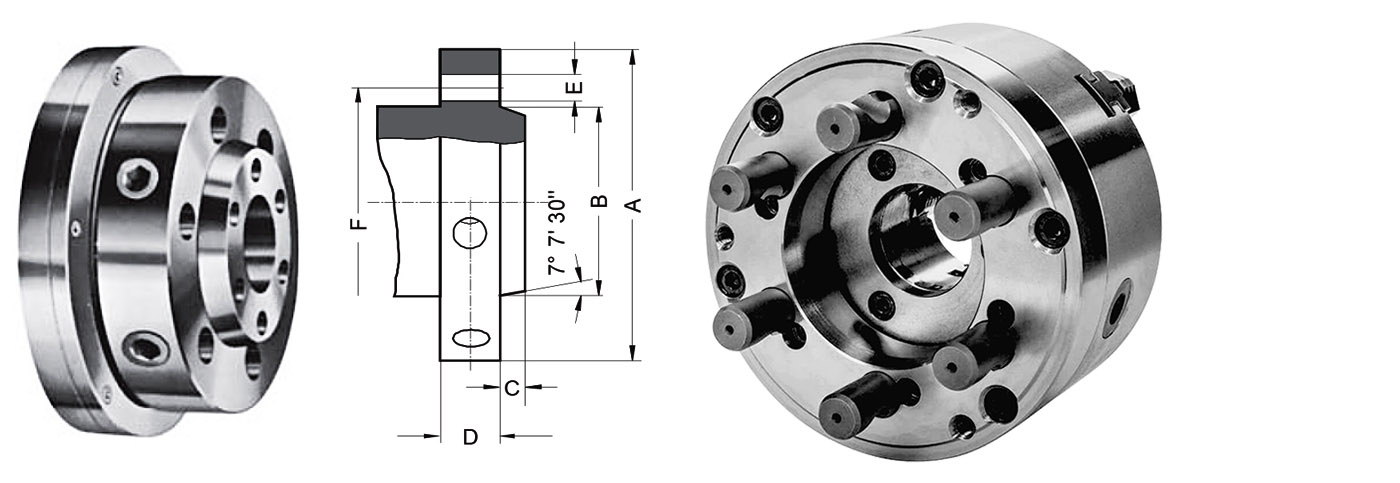

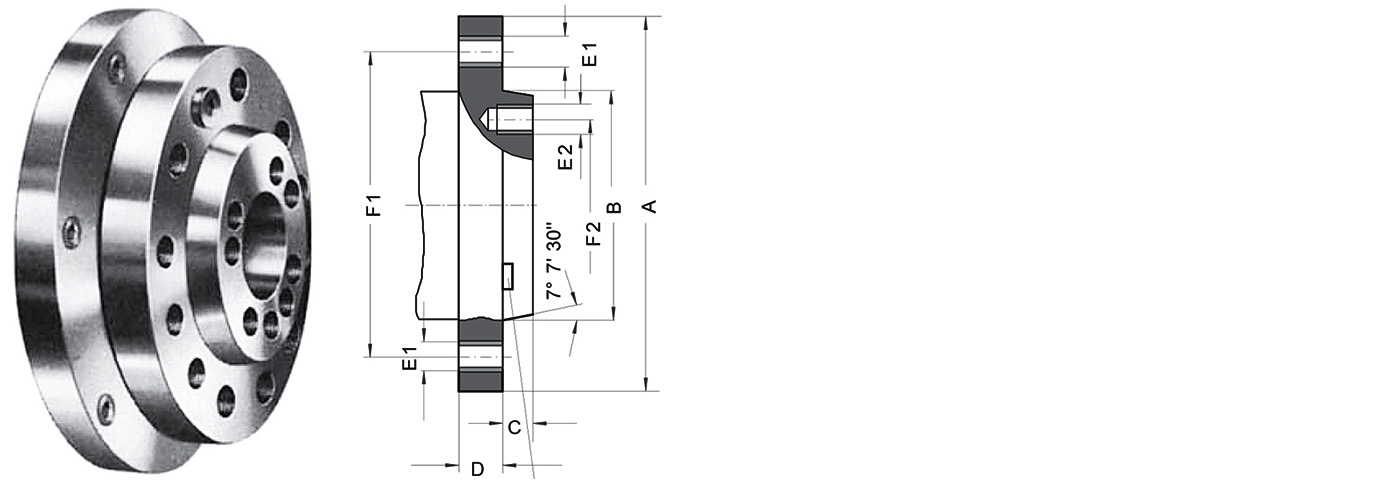

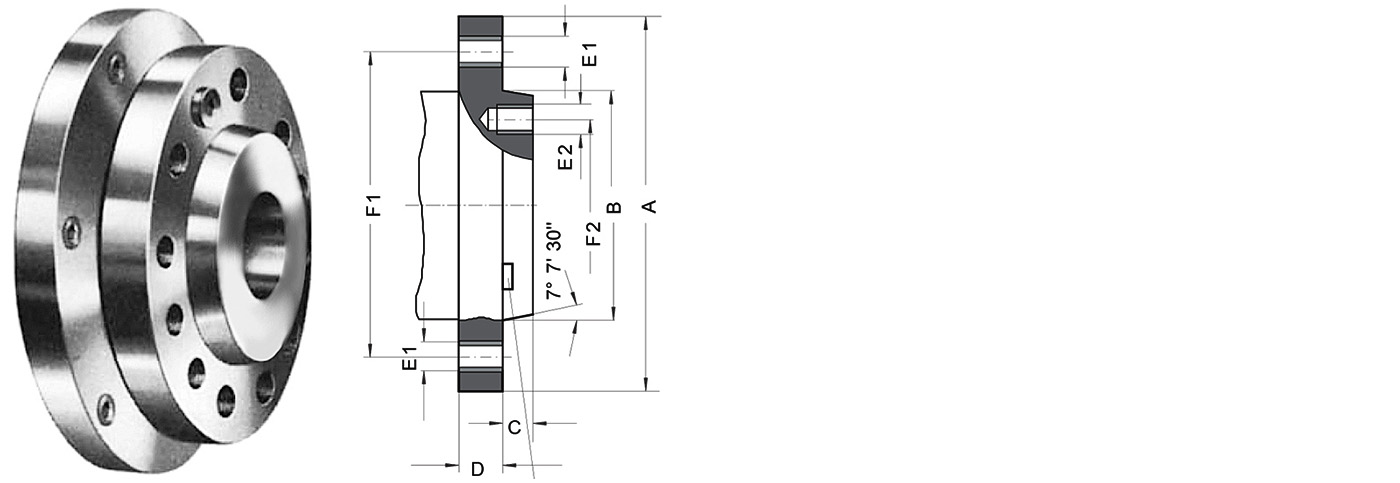

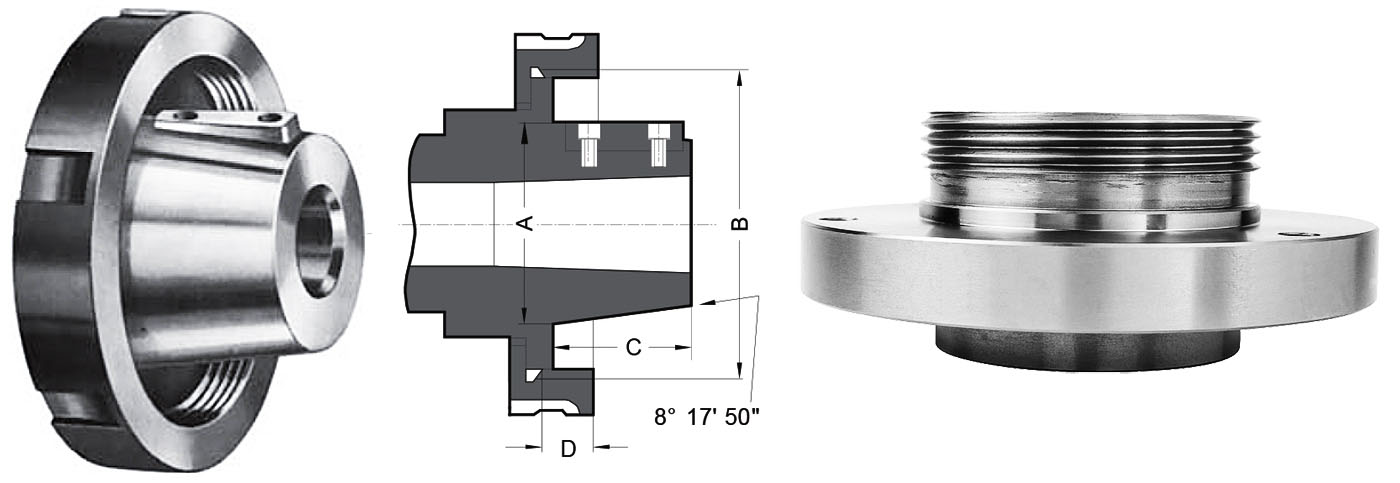

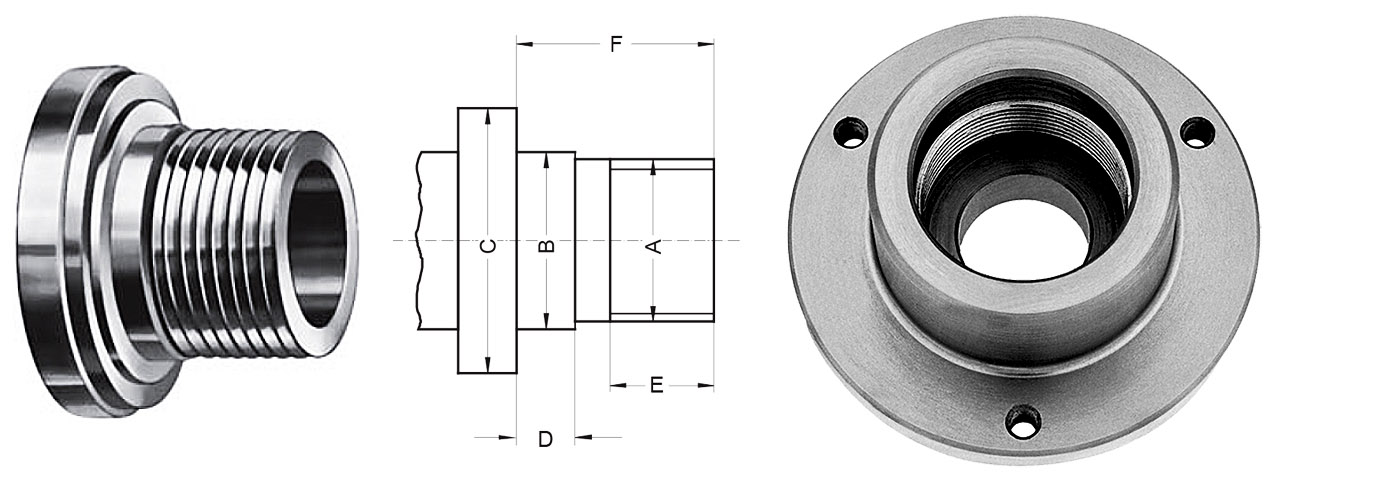

The lathe i agreed to purchase I believe is an A1-5 mount. I've never had one. In googling it looks like it's the same size and taper as the D1 cam lock chucks but it bolts to the spindle.

Also, the A1 has bolts inside the taper and outside. An A2 has them just on the outside, so i could use an A2-5 chuck?I think?

With this type of spindle do you have to get specific chucks made for the A1 so that they have holes for the bolts to go thru? Or can you still get like any plain chuck and just get the A1-5 back plate? For example, I have a bison 6 jaw chuck with an L00 back plate, can I just get the A1 back plate for it?

Thanks

Jeff in long beach

Sent from my LM-V405 using Tapatalk

The lathe i agreed to purchase I believe is an A1-5 mount. I've never had one. In googling it looks like it's the same size and taper as the D1 cam lock chucks but it bolts to the spindle.

Also, the A1 has bolts inside the taper and outside. An A2 has them just on the outside, so i could use an A2-5 chuck?I think?

With this type of spindle do you have to get specific chucks made for the A1 so that they have holes for the bolts to go thru? Or can you still get like any plain chuck and just get the A1-5 back plate? For example, I have a bison 6 jaw chuck with an L00 back plate, can I just get the A1 back plate for it?

Thanks

Jeff in long beach

Sent from my LM-V405 using Tapatalk