-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

PM-1127VF-LB Lathe vs PM-1228VF-LB Precision Lathe?

- Thread starter Tired&Retired

- Start date

- Joined

- Sep 7, 2020

- Messages

- 111

Heck, I am continually thinking through the pickup and install trying to anticipate every contingency. But honestly, it doesn't keep me awake at night. Just expect the worst, be prepared for it, then usually when the dust settles, it winds up being easier than you expected.

- Joined

- Sep 7, 2020

- Messages

- 111

Well, the PM-1228VF-LB showed up today. Met the UPS Freight truck at the local Walmart and the guy moved the crate into the bed of my wife's truck easily with no muss or fuss. He did have to swing it around for me so that the headstock would be in the position I would need to remove it and move it to the workbench.

Got the truck and lathe sitting in a bay in my garage right now, with the top and sides off of the crate, and the boxes of accessories removed. Superficial inspection doesn't show any damage or anything that looks out of place. One small screw missing on the backside of the head stock, and a couple of small dents on the splash shield. BTW, I was REAL glad to see that the chip pan was bolted to the underside of the crate lid, as I was concerned that I was going to have to lift the lathe with the shop hoist just to get the chip pan out so I could mark the holes to drill in my new work table.

Need to clean off all the gunk on the metal surfaces, of course, but I will do that after I move it in place on the work table. Not sure what would be best to remove the coating, but I'm going to give WD-40 a try first. I watched several videos with various suggestions, one even suggesting lighter fluid. Not sure I would be enthused about that at all.

I took LOADS of photos, but haven't had time to even look at them yet. Heck, I don't even know what day it is! Things have been pretty busy lately, and I am RETIRED! I have no idea how I got anything done when I was working.

Probably will be drilling the holes in the worktable tomorrow sometime. The rest will all be in due time.

Oh yeah, the lathe looks REALLY nice. Much better than that POS Chinesium lathe I bought off of Ebay and sent back to the seller.

Much better than that POS Chinesium lathe I bought off of Ebay and sent back to the seller.

Got the truck and lathe sitting in a bay in my garage right now, with the top and sides off of the crate, and the boxes of accessories removed. Superficial inspection doesn't show any damage or anything that looks out of place. One small screw missing on the backside of the head stock, and a couple of small dents on the splash shield. BTW, I was REAL glad to see that the chip pan was bolted to the underside of the crate lid, as I was concerned that I was going to have to lift the lathe with the shop hoist just to get the chip pan out so I could mark the holes to drill in my new work table.

Need to clean off all the gunk on the metal surfaces, of course, but I will do that after I move it in place on the work table. Not sure what would be best to remove the coating, but I'm going to give WD-40 a try first. I watched several videos with various suggestions, one even suggesting lighter fluid. Not sure I would be enthused about that at all.

I took LOADS of photos, but haven't had time to even look at them yet. Heck, I don't even know what day it is! Things have been pretty busy lately, and I am RETIRED! I have no idea how I got anything done when I was working.

Probably will be drilling the holes in the worktable tomorrow sometime. The rest will all be in due time.

Oh yeah, the lathe looks REALLY nice.

- Joined

- Oct 4, 2016

- Messages

- 7,020

Happy times for sure, just the drudgery of setting up. Then you work on the muscle/mental memory for where things are, and how the machine sounds when it's not happy. I went past my normal machining hours tonight just to get a little bit ahead on my project. I was on a final cleanup pass, everything going great, then I reached with my hand to move some swarf that was piling up, and hit the cross slid handle digging the tool in a couple of thousands, what a pain. It's fixed, and I'm done.....Have fun soon

- Joined

- Jan 2, 2019

- Messages

- 6,526

Well, the PM-1228VF-LB showed up today. Met the UPS Freight truck at the local Walmart and the guy moved the crate into the bed of my wife's truck easily with no muss or fuss. He did have to swing it around for me so that the headstock would be in the position I would need to remove it and move it to the workbench.

Got the truck and lathe sitting in a bay in my garage right now, with the top and sides off of the crate, and the boxes of accessories removed. Superficial inspection doesn't show any damage or anything that looks out of place. One small screw missing on the backside of the head stock, and a couple of small dents on the splash shield. BTW, I was REAL glad to see that the chip pan was bolted to the underside of the crate lid, as I was concerned that I was going to have to lift the lathe with the shop hoist just to get the chip pan out so I could mark the holes to drill in my new work table.

Need to clean off all the gunk on the metal surfaces, of course, but I will do that after I move it in place on the work table. Not sure what would be best to remove the coating, but I'm going to give WD-40 a try first. I watched several videos with various suggestions, one even suggesting lighter fluid. Not sure I would be enthused about that at all.

I took LOADS of photos, but haven't had time to even look at them yet. Heck, I don't even know what day it is! Things have been pretty busy lately, and I am RETIRED! I have no idea how I got anything done when I was working.

Probably will be drilling the holes in the worktable tomorrow sometime. The rest will all be in due time.

Oh yeah, the lathe looks REALLY nice.Much better than that POS Chinesium lathe I bought off of Ebay and sent back to the seller.

So happy to hear you ended up with something that will serve you well. Your wife was right, just get the good one and stop worrying.

Looking forward to pictures.

John

- Joined

- Sep 7, 2020

- Messages

- 111

Well, did a preliminary visual inspection of the lathe and found a few minor issues. Nothing a show stopper, though.

Looks like a big scratch on the apron that I thought might be a crack. A closer look makes it appear to be a scratch, but it seems apparent there has been some fixup work done there with the set screw being painted over.

Then there are a few decals missing on the headstock that should be there, based on what I have seen not only on PM's website but also on all the videos and photos I have seen.

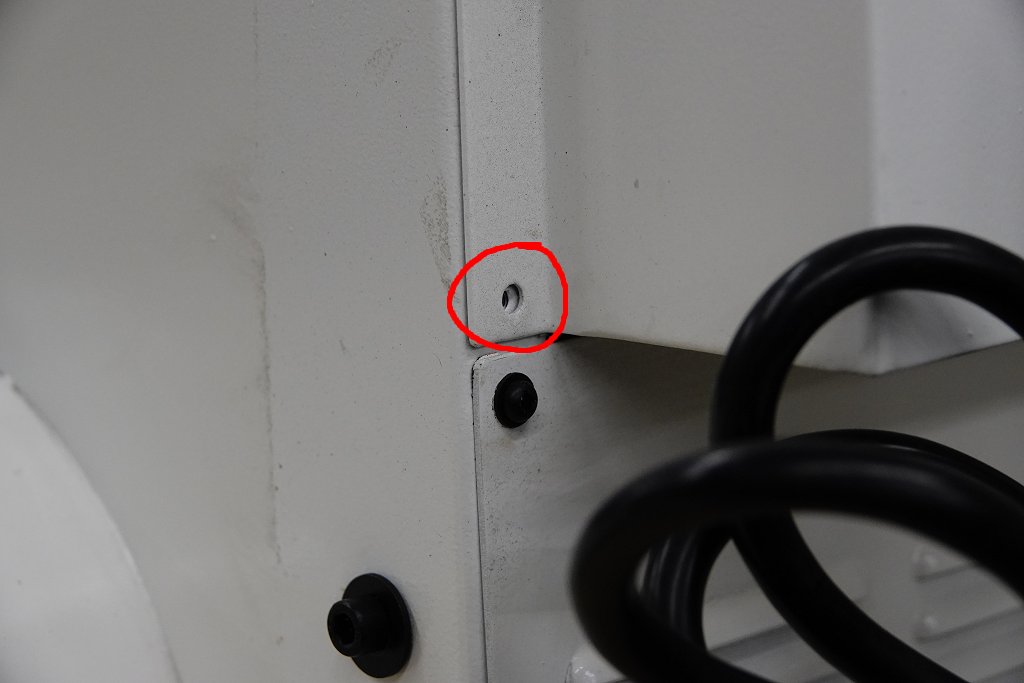

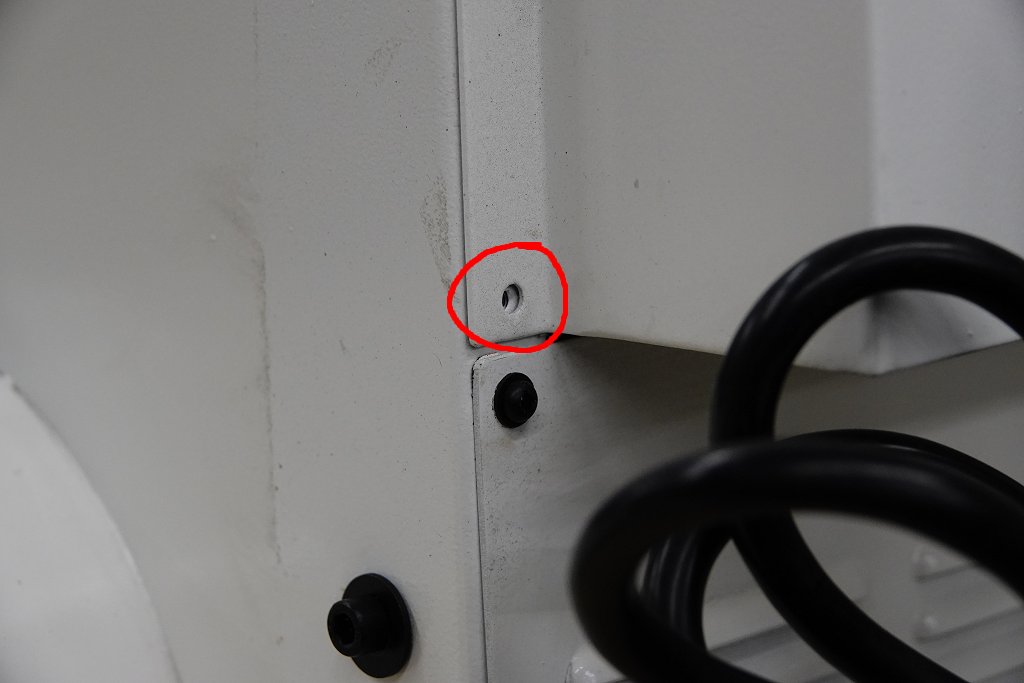

Two screws are missing in back of the headstock holding a panel in place there.

Then I noted that the motor is only rated at 1100 watts which equates to 1.475 horsepower, whereas there is supposed to be a 2 horsepower motor in this machine.

Couple of other minor things: The 4 jaw chuck has the box gouged a bit because it was apparently shoved behind the carriage, and there is a metal shield of some sort back there that cut into the box. I haven't opened the box yet to see if the chuck itself has gotten gouged. Then the lever for the half nut knob had fallen off and was laying in the bottom of the crate.

Like I said, no show stoppers there, but the lack of the decals does concern me as someone just wasn't paying much attention when they opened up the crate to put the accessories inside there. And I am not all that keen on getting a weaker motor than was shown in the manual and elsewhere.

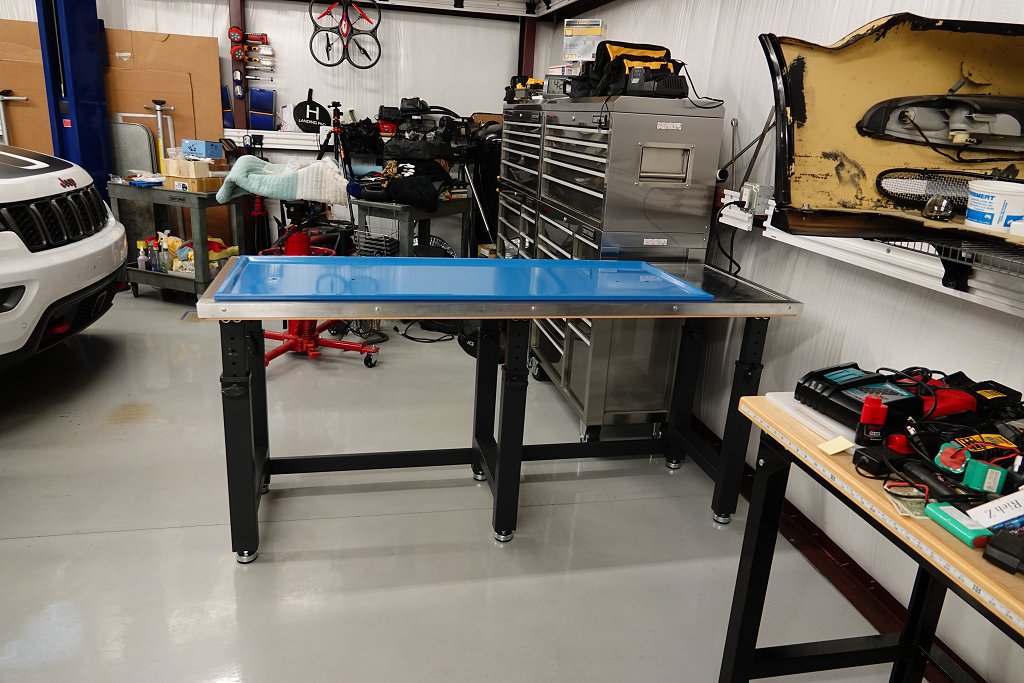

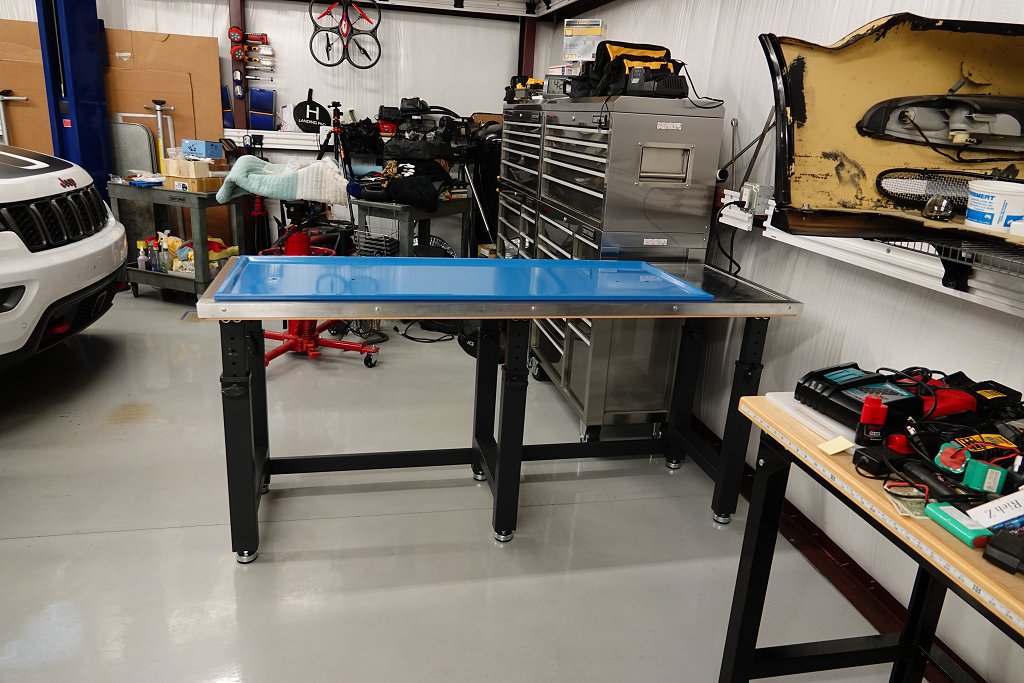

Still haven't applied power to it nor checked any alignments. Drilled the mounting holes into the work table yesterday, and am now reconsidering where I want to put the worktable in the garage. Which will mean taking at least a day to move things around. Then I need to level the worktable, then move the lathe from the bed of the pickup truck onto the worktable. Once the lathe is on the worktable, I will be cleaning all the gunk off of the lathe before doing anything else. So I'm not expecting to apply power to the thing until maybe the weekend.

Oh, I sent messages to PM about the issues noted above, but as of yet have not received any replies.

Looks like a big scratch on the apron that I thought might be a crack. A closer look makes it appear to be a scratch, but it seems apparent there has been some fixup work done there with the set screw being painted over.

Then there are a few decals missing on the headstock that should be there, based on what I have seen not only on PM's website but also on all the videos and photos I have seen.

Two screws are missing in back of the headstock holding a panel in place there.

Then I noted that the motor is only rated at 1100 watts which equates to 1.475 horsepower, whereas there is supposed to be a 2 horsepower motor in this machine.

Couple of other minor things: The 4 jaw chuck has the box gouged a bit because it was apparently shoved behind the carriage, and there is a metal shield of some sort back there that cut into the box. I haven't opened the box yet to see if the chuck itself has gotten gouged. Then the lever for the half nut knob had fallen off and was laying in the bottom of the crate.

Like I said, no show stoppers there, but the lack of the decals does concern me as someone just wasn't paying much attention when they opened up the crate to put the accessories inside there. And I am not all that keen on getting a weaker motor than was shown in the manual and elsewhere.

Still haven't applied power to it nor checked any alignments. Drilled the mounting holes into the work table yesterday, and am now reconsidering where I want to put the worktable in the garage. Which will mean taking at least a day to move things around. Then I need to level the worktable, then move the lathe from the bed of the pickup truck onto the worktable. Once the lathe is on the worktable, I will be cleaning all the gunk off of the lathe before doing anything else. So I'm not expecting to apply power to the thing until maybe the weekend.

Oh, I sent messages to PM about the issues noted above, but as of yet have not received any replies.

- Joined

- Sep 7, 2020

- Messages

- 111

Matt got back to me about the issues. He said they have discontinued putting on those decals I am missing. But he is going to find me one, since I would like to have the model number displayed on the machine. He wants me to check out everything thoroughly to see if there is anything else I need before sending the decal and the missing screws. He also feels that the scratch is nothing more than that, only in the paint surface.

Might be able to move the lathe over to the work table tomorrow. Got the worktable in position, drilled the mounting holes and leveled the table.

Might be able to move the lathe over to the work table tomorrow. Got the worktable in position, drilled the mounting holes and leveled the table.

- Joined

- Sep 7, 2020

- Messages

- 111

Oh, about the 1.5hp motor instead of the 2hp. Apparently this had something to do with the implementation of tariffs from China. That were apparently lifted later. So I'm not sure if this is a permanent change in the specs or if they will resume with the 2hp sometime in the future, and I just got mine at the wrong time. Matt says I won't notice any difference, but I'm thinking that the first time (if ever?) I bog down the motor by pushing it too hard, I will find myself wishing that I had the 2hp motor in there.

- Joined

- Oct 4, 2016

- Messages

- 7,020

If I push the tail stock drilling in aluminum hard I can hear mine "labor" a little bit, and if I do not clear chips, and they load up it will stall. This is if I'm going past 6" with 11/16 up to 1.125. I do not have the best points on my bits too

With the right HSS, or indexable tools reasonable DOC is not an issue, too aggressive just stresses the tools more.

With the right HSS, or indexable tools reasonable DOC is not an issue, too aggressive just stresses the tools more.