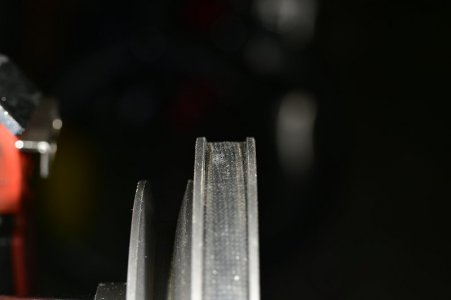

Well, I went and ordered several different sized belts for the 1228 from an outfit called OffRoadBelts.com. Great people and very reasonable prices, BTW. So when they came in, I tried them all, and the best fitting one was the 10mm x 875mm one. Guess I could have saved some time and trouble just by going by Bryan40g's suggestion, but I just wanted to double check for my own satisfaction. But that did give me a good starting point to work around. Plus I had something perhaps different in mind to try. I actually went and bought some small tools for installing and removing V-belts, but I decided I didn't want to pre-stress the belt by having to force it up and over the lips of the pulleys to place the belt in the grooves. My idea was to pull off the pulley from the motor shaft, position the belt into the pulley grooves, and then slip the pulley back onto the motor shaft. With the 10x875 belt, this was pretty much an EXACT fit and worked like a charm. Only had to do some minor tugging to get the pulley onto the motor shaft, lining it up properly, tap it lightly with a soft mallet, and it was done. Actually it feels like I won't even need to use the tensioner at all to start off with as it is tight enough, as is. I also selected a cogged belt, as I felt it would be a better match for this application than a solid belt. Apparently cogged belts are better on smaller pulley diameters.

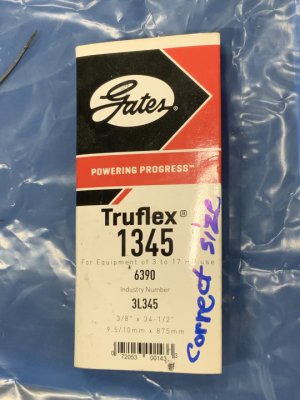

I also received the free replacement belt from PrecisionMatthews (thanks Mike!). Oddly enough it states right on the belt that it is an 838mm long belt, and it measures as being 9.5mm or so in width. I bought a belt measuring tool, and according to it, this belt actually measures 10mm x 875mm, regardless of what is imprinted upon it. Little wonder this was so confusing. I did pass this info onto Mike at PM, btw.

So all is well that ends well. Have the new belt on the machine and a couple of spares to boot.

Pics are attached of the OffRoadBelts cogged belt mounted on the PM-1228 and then measurements of the replacement belt I got from PM.