Hey everyone... Long time lurker who finally purchased his first lathe and have what I am certain is a completely cherry question to ask. But for the life of me I can't figure this out, so here I am.

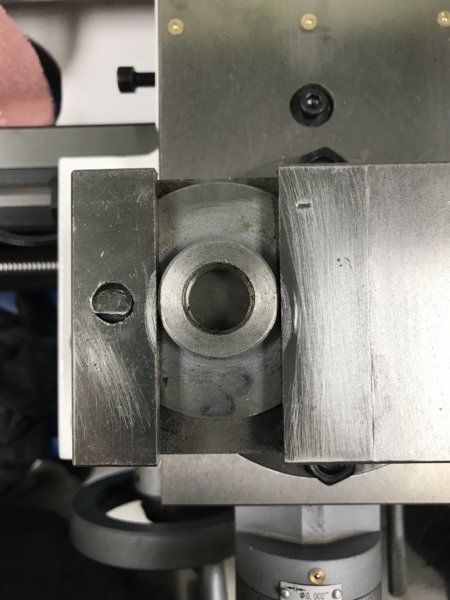

I am attempting to swap out the tool post that came preinstalled on the lathe with the QCTP that I purchased from Precision Matthews. I loosened the top nut, pulled the tool post off, unscrewed the bolt, and am left with a nut in the bottom of the top slide that wont come out. There is some type of spring loaded indent that I have fiddled with, turned, pressed, etc that is clearly holding the nut in and preventing it from sliding out. No matter what I try it simply won't come.

Am attaching a photo here for reference. I know I am going to feel sheepish when someone points out how simple it is to remove. But after an hour and a half making an attempt I am final here to ask for help.

I am attempting to swap out the tool post that came preinstalled on the lathe with the QCTP that I purchased from Precision Matthews. I loosened the top nut, pulled the tool post off, unscrewed the bolt, and am left with a nut in the bottom of the top slide that wont come out. There is some type of spring loaded indent that I have fiddled with, turned, pressed, etc that is clearly holding the nut in and preventing it from sliding out. No matter what I try it simply won't come.

Am attaching a photo here for reference. I know I am going to feel sheepish when someone points out how simple it is to remove. But after an hour and a half making an attempt I am final here to ask for help.