- Joined

- Nov 27, 2012

- Messages

- 7,855

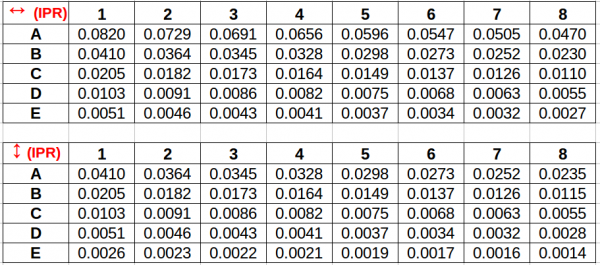

I haven't read the entire thread so forgive me if I'm totally missing the question but TPI is not the same as feed rate. TPI would be teeth per the distance of an inch so you can caluculate the travel but the feed rates listed on the chart is when using the power feed rod instead of the leadscrew, feedrate is Inch Per Revolution. So if you set your gearbox to say .005", the carriage should travel .005" for one complete revoution of the spindle. You can somewhat verify this with an indicator or DRO with the power feed engaged & turn the spindle by hand.I know this is an old post but I've wondered this myself.

Can someone explain to an idiot like me how the feed rate is calculated?

I have always just divided the TPI into 1 to find the decimal equivalent but the chart above shows completely different results.

For example I was machining last a part last night using D-6 on the Norton gearbox. The chart on my PM1340GT indicates that D-6 is the gear position for 48 TPI (Threads Per Inch). If you calculate that out isn't is 1/48= .020833 or roughly .021"? Yet in the chart above for D-6 it shows .0068".

Can someone please explain?

Thank you.