- Joined

- Apr 16, 2022

- Messages

- 2

G'day Guys

I am thinking about upgrading my lathe to a PM-1440GT. Here in Australia the PM brand is sold under a different name, but it's the same machine..

I am a Gunsmith and so a large part of what i do is cut threads. Mainly imperial/UN threads but occasionally metric as well.

As part of my research into the machine I have been looking at the lead screw gear ratios of of the PM-1440 and comparing to other machines to see what threads can be cut with minimal gear changes in the back cover. To that end i decided to create a spreadsheet that would calculate the ratio of every possible lever position.

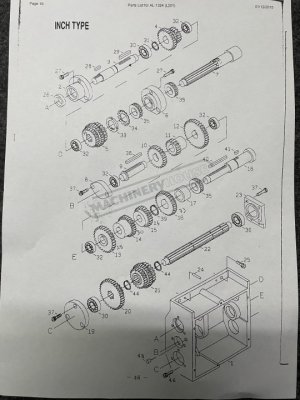

I have found the gearbox details online that shows the layout of the gearbox with the correct number of teeth on each gear set etc and was able to create the spreadsheet that calculates the final ratios for each lever position..

After I was done, I also found some one else’s spreadsheet (On this forum ) that confirms my own so I’m confident I have it correct..

) that confirms my own so I’m confident I have it correct..

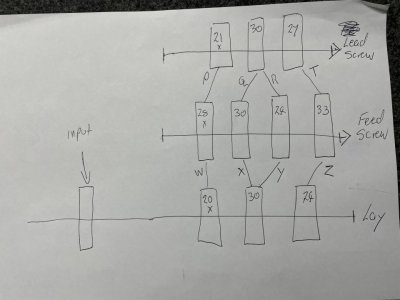

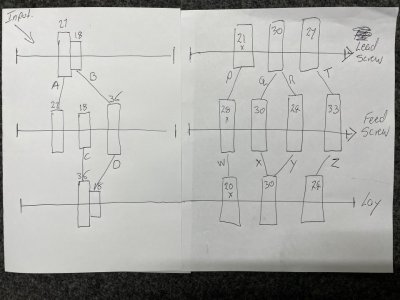

I’ve attached a few pics of the layout of the gears and I have confirmed 100% that it’s correct (the A-B C-D levers section is not shown on my sketch) However one thing has me stumped..

How can the top and bottom 30 tooth gears mesh with the center 30 tooth gear AND also the center 24 tooth gear?? IE XQ and YR.

The shaft centers are fixed and by all rights the 24 tooth center gear should be smaller dia and should not be able to mesh with the 30 tooth top and bottom gears.. Can someone explain how that works??

My first thought was some odd tooth profile that some how makes the 24 and 30 tooth center gears the same PD, but I just can’t see how that’s possible?

Has anyone ever had the covers off and have pictures of the feed box?

Thoughts??

Cheers

Lee

I am thinking about upgrading my lathe to a PM-1440GT. Here in Australia the PM brand is sold under a different name, but it's the same machine..

I am a Gunsmith and so a large part of what i do is cut threads. Mainly imperial/UN threads but occasionally metric as well.

As part of my research into the machine I have been looking at the lead screw gear ratios of of the PM-1440 and comparing to other machines to see what threads can be cut with minimal gear changes in the back cover. To that end i decided to create a spreadsheet that would calculate the ratio of every possible lever position.

I have found the gearbox details online that shows the layout of the gearbox with the correct number of teeth on each gear set etc and was able to create the spreadsheet that calculates the final ratios for each lever position..

After I was done, I also found some one else’s spreadsheet (On this forum

I’ve attached a few pics of the layout of the gears and I have confirmed 100% that it’s correct (the A-B C-D levers section is not shown on my sketch) However one thing has me stumped..

How can the top and bottom 30 tooth gears mesh with the center 30 tooth gear AND also the center 24 tooth gear?? IE XQ and YR.

The shaft centers are fixed and by all rights the 24 tooth center gear should be smaller dia and should not be able to mesh with the 30 tooth top and bottom gears.. Can someone explain how that works??

My first thought was some odd tooth profile that some how makes the 24 and 30 tooth center gears the same PD, but I just can’t see how that’s possible?

Has anyone ever had the covers off and have pictures of the feed box?

Thoughts??

Cheers

Lee