- Joined

- May 27, 2016

- Messages

- 3,469

Hobby Machine sized small mills that we have space for, and can reasonably save up for, and has some potential for some upgrades like CNC. I really wanted to go the route of those folk who have successfully fitted CNC conversions. We know all this kit comes from China. Several brands, but let us not say "alike", because they are more than that! . One gets small variations, but alike enough to say "more than clones". What I see is stuff so alike, it does kinda look like the Cosmoline was probably applied to all of them by the same urchin in China! Right down to the symbols on the plastic push-buttons!

In UK, options for buying Precision Mattews were always limited. There are real problems if wanting to import. At the time I ordered, UK was in the last stages of being in the EU, though that arrangement was shortly to crash out! I opted to go with the Cormak from Poland, though only a day or two into encountering the Brexit mess!. Cormak do precision CNC stuff in Europe.

OK, I admit I may have overdone this to the point of boredom, for which I apologize. I could have used a one-liner like "In that size, they all come from China and are pretty much similar", but this whole scene has got my hopes up. They are not just "similar". They have so much common DNA that I think it probable that the main metal chunks all saw the same cutters in the same manufacturing facility. It is possible that some, say made with Precision Matthews, or Cormak logos, might have been finished to a better specification, (for more money). There are some variations in the motors. Some are described as 750W, others as 1kW, some as 1HP. Some might have a inches tape riveted on. There might be plastic gears in there.

Notice the common giveaway. The type number will be some combination with a "25" in it, and if there is a "V" or a "M" or both in any combination, and when they look alike, it kind of makes it a certainty! In the important features, these are maybe more than just "clones". They might be simply the very same steel, smelling of the very same oil from the very same drum!

Hopes for CNC Conversion Kits Compatibility?

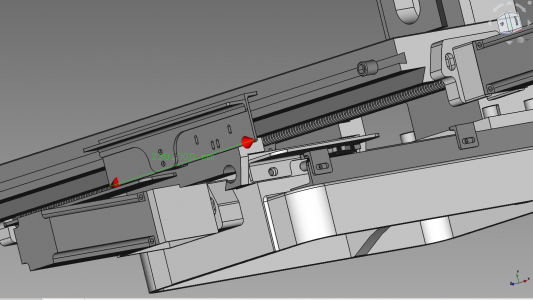

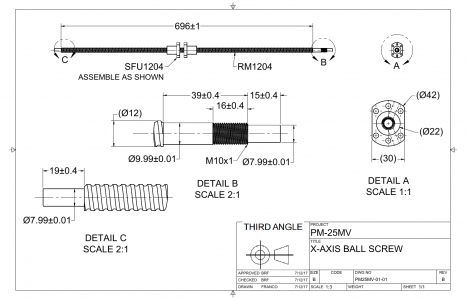

The whole reason I have hopes is that I now think it possible all those CNC conversion project videos for PM-25, Grizzly, and others, the plans, the various ballscrew + bearings and motors conversion kits from vendors, might, down at the place they get bolted on, be nicely compatible. Sadly, unless there is a UK outlet for the kits, or they can be found on eBay, I might still be looking at an import headache, or I make the machine manufacture it's own conversion kit to my own preference.

There are slight differences, but here's why I think these all came from the same square mile..

Cormak HK-25L (Metric from Poland). I opted for the one with the X-drive motor. It's Polish, from an outfit with a good rep.

--------------------------

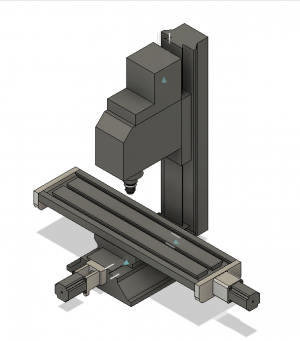

Looking familiar? So how about Precision Matthews PM-25MV

You can get it with optional stand, X-motor drive, Imperial units, other voltage options, etc.

---------------------------

Yes, we know that when we consider Grizzly G0704, it is also described as a "PM clone", though I am not sure which was there first. I have even seen a video doing a "compare" between them. The Grizzly was about $1350, compared to PM about $1600 to $1700. Maybe PM paid for a better build? This type is known to feature at least one plastic gear, which folk simply change out.

-----------------------------

From Germany, we can have Weiss-VM25. This one is so exactly like the Cormak, I think the only difference is one label!

The one shown is without the motorized X-drive option.

-------------------------------

Now that I am onto this game of "spot how identical we are", I may as well keep going, though I dare say those I find might not comprise even a minority list!

One can find the Titan TM25V. That one even has the identical start/stop switches and electrical panel layout as PM-25MV, and is, I think 110 Volts type

---------------------------------

We can discover the RCOG-25V. Same as, same as..

--------------------------------

OK Graham- that's enough already!

In UK, options for buying Precision Mattews were always limited. There are real problems if wanting to import. At the time I ordered, UK was in the last stages of being in the EU, though that arrangement was shortly to crash out! I opted to go with the Cormak from Poland, though only a day or two into encountering the Brexit mess!. Cormak do precision CNC stuff in Europe.

OK, I admit I may have overdone this to the point of boredom, for which I apologize. I could have used a one-liner like "In that size, they all come from China and are pretty much similar", but this whole scene has got my hopes up. They are not just "similar". They have so much common DNA that I think it probable that the main metal chunks all saw the same cutters in the same manufacturing facility. It is possible that some, say made with Precision Matthews, or Cormak logos, might have been finished to a better specification, (for more money). There are some variations in the motors. Some are described as 750W, others as 1kW, some as 1HP. Some might have a inches tape riveted on. There might be plastic gears in there.

Notice the common giveaway. The type number will be some combination with a "25" in it, and if there is a "V" or a "M" or both in any combination, and when they look alike, it kind of makes it a certainty! In the important features, these are maybe more than just "clones". They might be simply the very same steel, smelling of the very same oil from the very same drum!

Hopes for CNC Conversion Kits Compatibility?

The whole reason I have hopes is that I now think it possible all those CNC conversion project videos for PM-25, Grizzly, and others, the plans, the various ballscrew + bearings and motors conversion kits from vendors, might, down at the place they get bolted on, be nicely compatible. Sadly, unless there is a UK outlet for the kits, or they can be found on eBay, I might still be looking at an import headache, or I make the machine manufacture it's own conversion kit to my own preference.

There are slight differences, but here's why I think these all came from the same square mile..

Cormak HK-25L (Metric from Poland). I opted for the one with the X-drive motor. It's Polish, from an outfit with a good rep.

--------------------------

Looking familiar? So how about Precision Matthews PM-25MV

You can get it with optional stand, X-motor drive, Imperial units, other voltage options, etc.

---------------------------

Yes, we know that when we consider Grizzly G0704, it is also described as a "PM clone", though I am not sure which was there first. I have even seen a video doing a "compare" between them. The Grizzly was about $1350, compared to PM about $1600 to $1700. Maybe PM paid for a better build? This type is known to feature at least one plastic gear, which folk simply change out.

-----------------------------

From Germany, we can have Weiss-VM25. This one is so exactly like the Cormak, I think the only difference is one label!

The one shown is without the motorized X-drive option.

-------------------------------

Now that I am onto this game of "spot how identical we are", I may as well keep going, though I dare say those I find might not comprise even a minority list!

One can find the Titan TM25V. That one even has the identical start/stop switches and electrical panel layout as PM-25MV, and is, I think 110 Volts type

---------------------------------

We can discover the RCOG-25V. Same as, same as..

--------------------------------

OK Graham- that's enough already!

Last edited: