- Joined

- Jul 31, 2020

- Messages

- 765

I have finally got around to figuring out how I am going to mount a DRO to my PM-728vt. This has meant a lot of crawling around the mill. I have been pretty pleased with what I have seen, once I started looking at the fabrication of the Mill in detail.

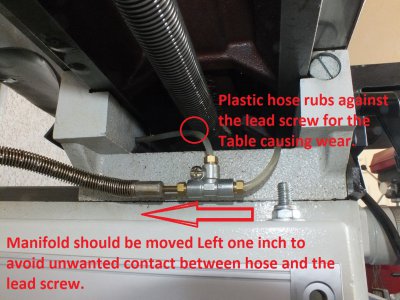

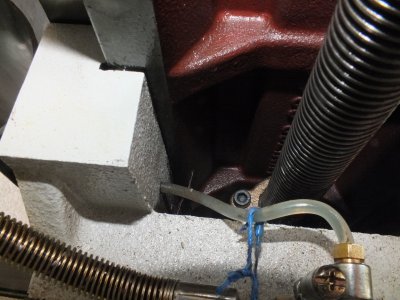

There has been one thing observed which is problematic. On the left hand side of the mill (under the table), a one-shot plastic oiler line bears against the lead screw which moves the X-Axis of the table. I ran my finger over the plastic oil tube, and discovered it was already getting a "flat spot" from the rubbing against the rotating lead screw. The table has been traversed a lot lately, to figure out DRO sensor placement, but still, the Mill only has a couple hours of use on the clock. (Mostly traversing back and forth to figure out DRO bracket placement.)

With a flat-spot already worn after such use, it points to eventual wear-through on this line with extended use, and will result in a lot of oil being dumped when the one-shot system is used. This could also result in precision surfaces not being properly lubricated (if the person is not alarmed by the increased pool of oil showing up in the tray). The one-shot system has a reputation for being "leaky", so I could see someone missing the early signs of a line failure.

As former Military, there was a common saying: "Don't come to me with a problem, unless you have the solution in your hip pocket". So let me propose a simple production fix. Move the oil manifold one inch to the left. This will keep the plastic hose from rubbing against the lead screw.

For the moment, I have an ugly fix for it. It will be replaced with something better after the DRO install is complete.

See pictures below.

There has been one thing observed which is problematic. On the left hand side of the mill (under the table), a one-shot plastic oiler line bears against the lead screw which moves the X-Axis of the table. I ran my finger over the plastic oil tube, and discovered it was already getting a "flat spot" from the rubbing against the rotating lead screw. The table has been traversed a lot lately, to figure out DRO sensor placement, but still, the Mill only has a couple hours of use on the clock. (Mostly traversing back and forth to figure out DRO bracket placement.)

With a flat-spot already worn after such use, it points to eventual wear-through on this line with extended use, and will result in a lot of oil being dumped when the one-shot system is used. This could also result in precision surfaces not being properly lubricated (if the person is not alarmed by the increased pool of oil showing up in the tray). The one-shot system has a reputation for being "leaky", so I could see someone missing the early signs of a line failure.

As former Military, there was a common saying: "Don't come to me with a problem, unless you have the solution in your hip pocket". So let me propose a simple production fix. Move the oil manifold one inch to the left. This will keep the plastic hose from rubbing against the lead screw.

For the moment, I have an ugly fix for it. It will be replaced with something better after the DRO install is complete.

See pictures below.

Attachments

Last edited: