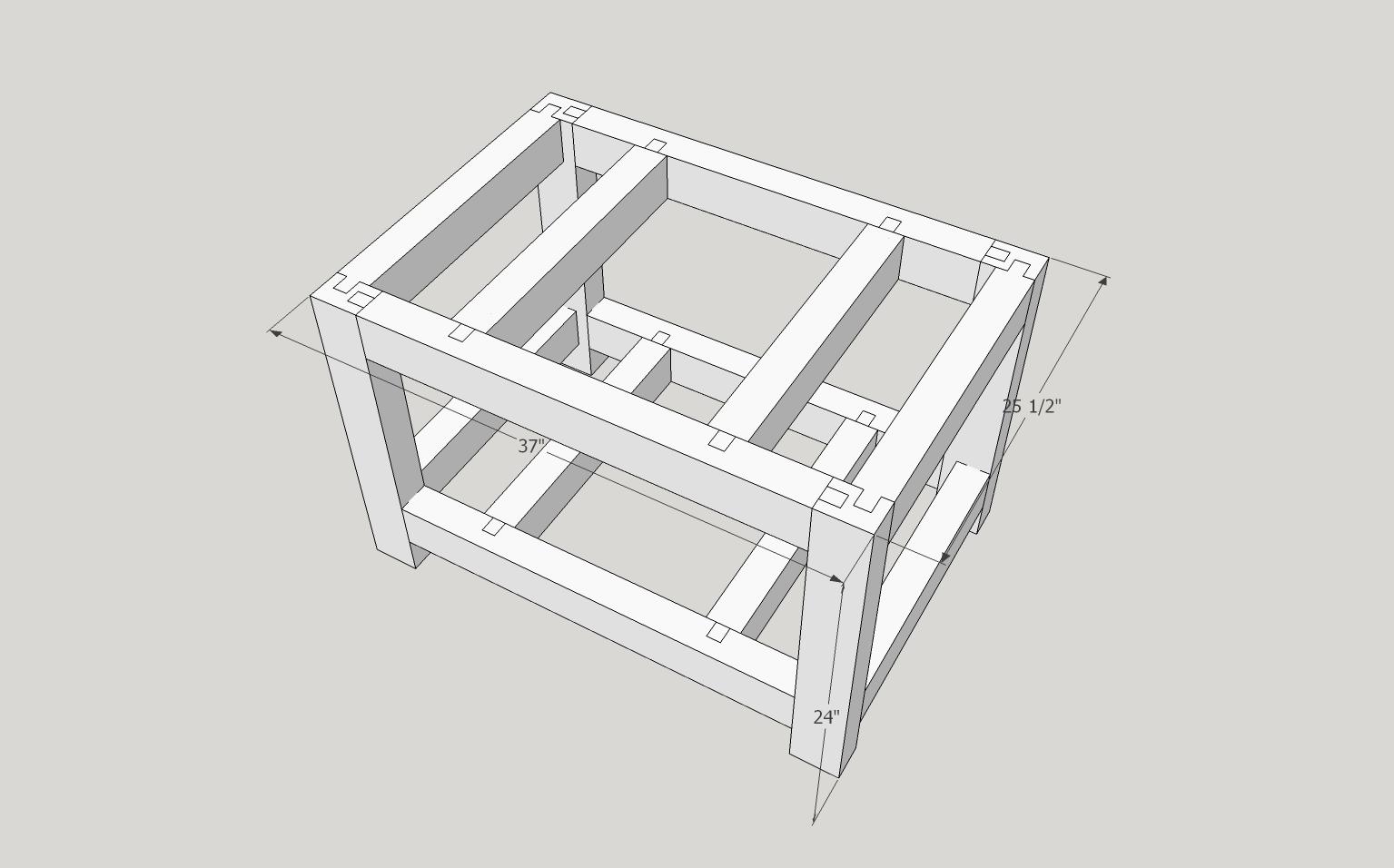

Hi. I took delivery of the PM-833T last week. I did not buy the PM stand because I plan to build my own using rectangular steel tubing, but don't have time right now to learn how to weld. I am going to build a stand using 2x4 lumber that I already have. A rough sketch is attached. It shows 24-inch height, but I have enough stock for 33-inch height. Top is double 3/4-inch plywood with hardboard laminated, so adding 1 3/4 inches to overall height. I can't decide on the height of the stand. I am 5'9" average. I am thinking a comfortable working height would be where I don't have to bend down to reach the part being milled.

What height is your stand for this mill? What is the height from the base of the mill to the jaw of a Kurt DX6 vise (mine is being shipped)?

What height is your stand for this mill? What is the height from the base of the mill to the jaw of a Kurt DX6 vise (mine is being shipped)?