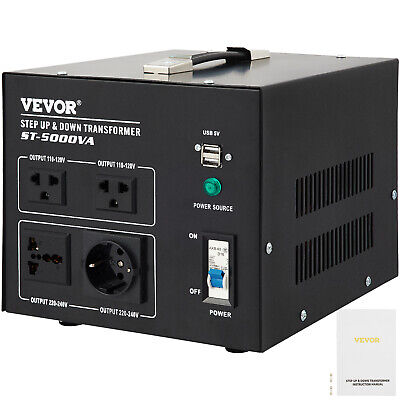

I have a 940V that I have been converting to CNC. Im on the final part which is the spindle and VFD. I have been going over the electronics in which

Im no electronics major trying to figure out how they are converting a 110V to 220 into the VFD? I have most of the factory electronics however they don't

have the wiring any more. I do remember the 110 enters the side switch and goes up to the top QM/Delixi DZ108-20. I'm trying to avoid running a 220volt

from the house into the garage to accomplish this. If anybody has any idea or help I'm all ears. Thank you.

Im no electronics major trying to figure out how they are converting a 110V to 220 into the VFD? I have most of the factory electronics however they don't

have the wiring any more. I do remember the 110 enters the side switch and goes up to the top QM/Delixi DZ108-20. I'm trying to avoid running a 220volt

from the house into the garage to accomplish this. If anybody has any idea or help I'm all ears. Thank you.