- Joined

- Mar 12, 2021

- Messages

- 63

Hello,

Being relatively new to working with machine tools I went looking for good info on lubricants, how/where/how often and application methods. Basically I wanted a cheat sheet so I can be sure to keep my new machine happy and running well for as long as possible. I have no problems with regular maintenance just like to have it documented.

Call me crazy but I at least thought it would be useful, and perhaps good reference for others. I will intend to keep this top post updated as some of the blanks or questions I have get filled in and add in some pictures of the given areas oilers etc.

RF 45/PM 932 series of mills. For reference the PM932V is what started this list but should apply to most all of the square column bench top type of mills of the RF45 clone family of products. Also Mobile oils referenced specifically as that is what I found conversion charts for/easy to get in manageable qty's

Location: X,Y axis ball oilers (near handles)

Lubricant: ISO 32 Oil (Mobile DTE24)

QTY: few drops/short squeeze

Frequency: every day before use.

Application Method: Oil can/squeeze bottle

Purpose: Lubricates leadscrew bearings (on x axis left side no bearings its just a bushing surface)

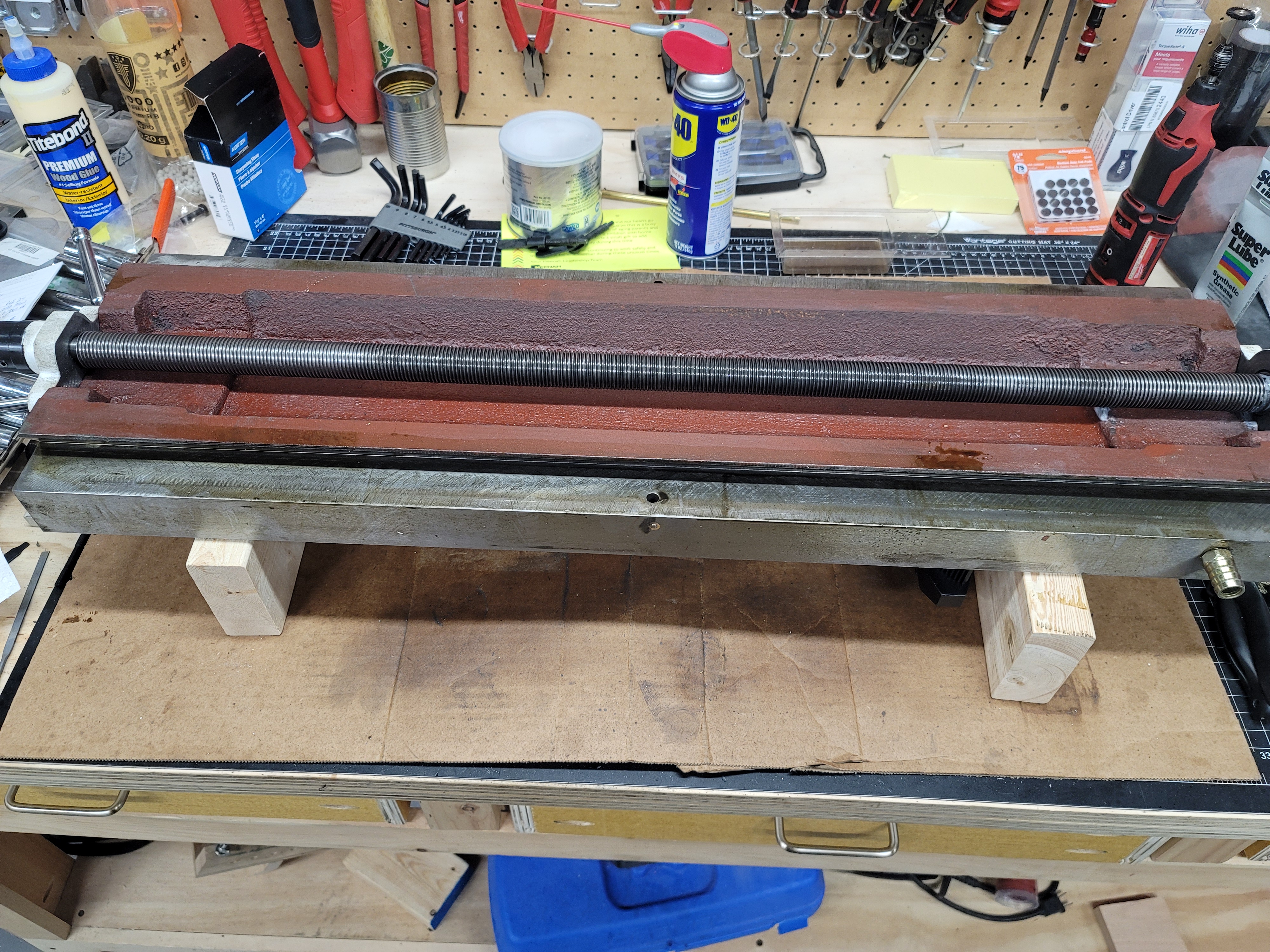

Location: X,Y Axis leadscrews

The large X axis leadscrew runs the length of the table can oil it via can or squeeze bottle run to one side oil and run to the other.

Y axis leadscrew only visible if you remove the rear bellow covers and move table forward apply oil and run table in and out.

Lubricant: ISO 32 Oil (Mobile DTE24)

QTY: few drops/short squeeze

Frequency: ???? weekly/monthly if you get jitters in DRO readout its time to oil them

Application Method: Oil can/squeeze bottle

Purpose: Lubricates leadscrews/ leadscrew "nut"

Location: Z Lead Screws

Lubricant: ISO 68 Oil (Mobile DTE26)

QTY: few drops/short squeeze

Frequency: ????

Application Method: Oil can/squeeze bottle

Purpose: Lubricates leadscrew bearings? (is it just the leadscrew bearings or is it supposed to work its way to lead screws as well?)

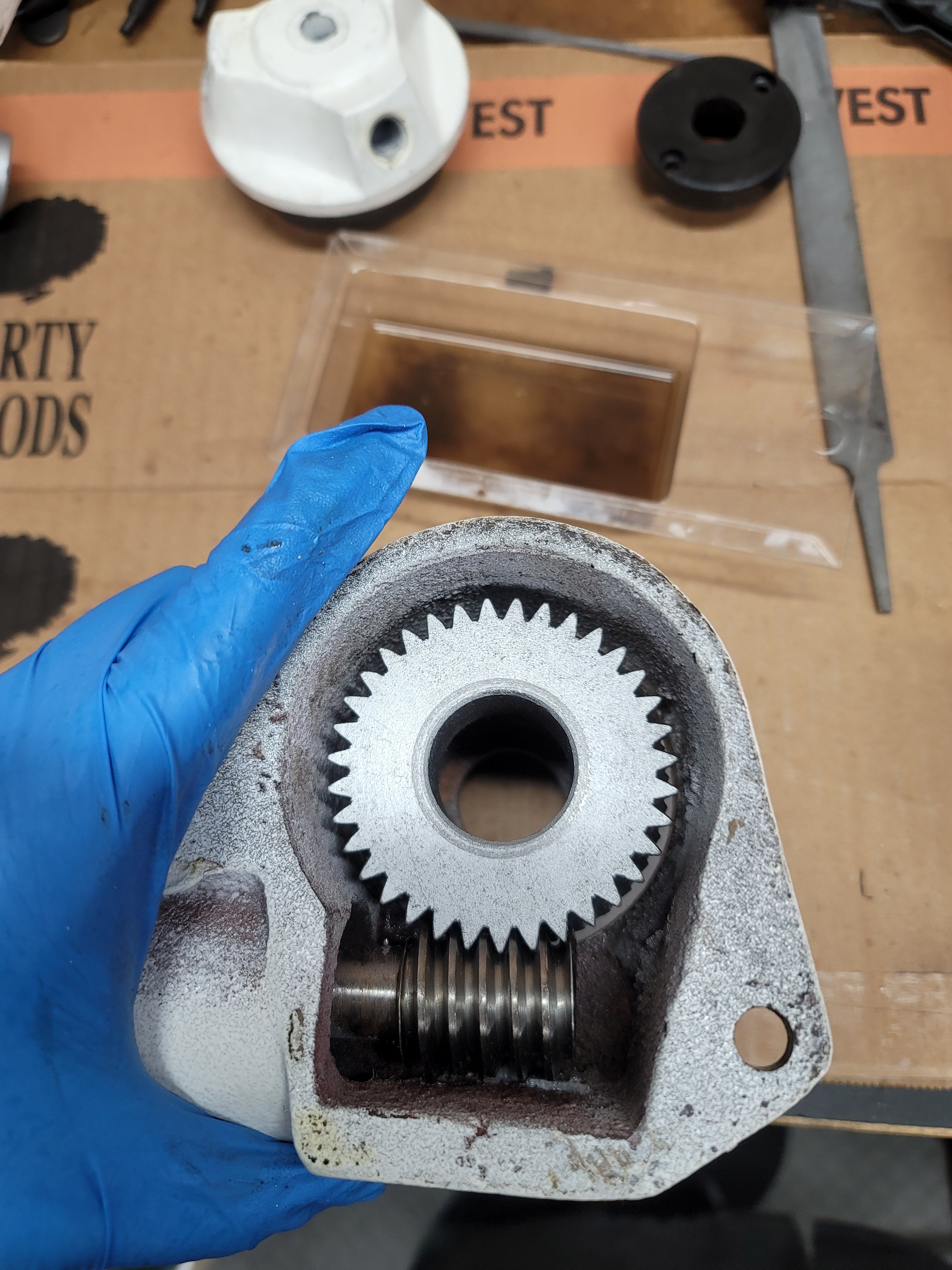

Location: Z axis "transfer gears" (gears than translate horizontal to vertical rotation)

Can access by removing bellows on the z axis or from the rear panel (on the 932V no rear panel but the large control box instead)

Lubricant: NLGL 2 grease (Super Lube NLGL 2 multi purpose synthetic grease with Syncolon), or Oil ISO 68 Oil (Mobile DTE26)

QTY: few drops/short

Frequency: ???? maybe annually if that

Application Method: grease gun, putty knife, fingers whatever works

Purpose: Lubricates the gears for the z axis handle, (still a thing even with z axis power feed the leadscrew will turn the handle shaft so its still a part interacting even if under much less loading)

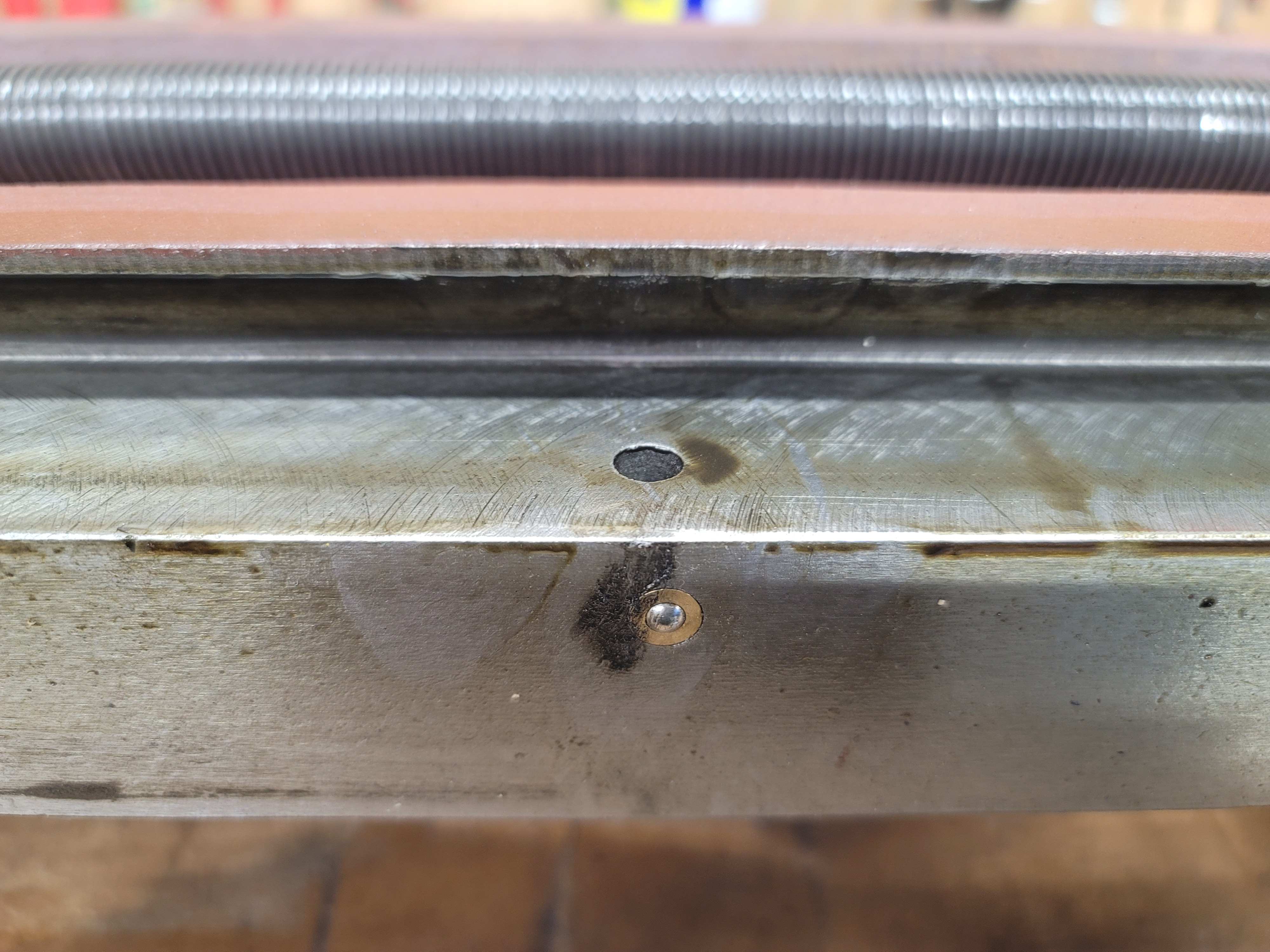

Location: X,Y,Z Ways (machines with a built in one shot oiler use that instead)

X axis has ball oilers on the 932, but just a large hole that feeds into the ways Y and Z still are manual application

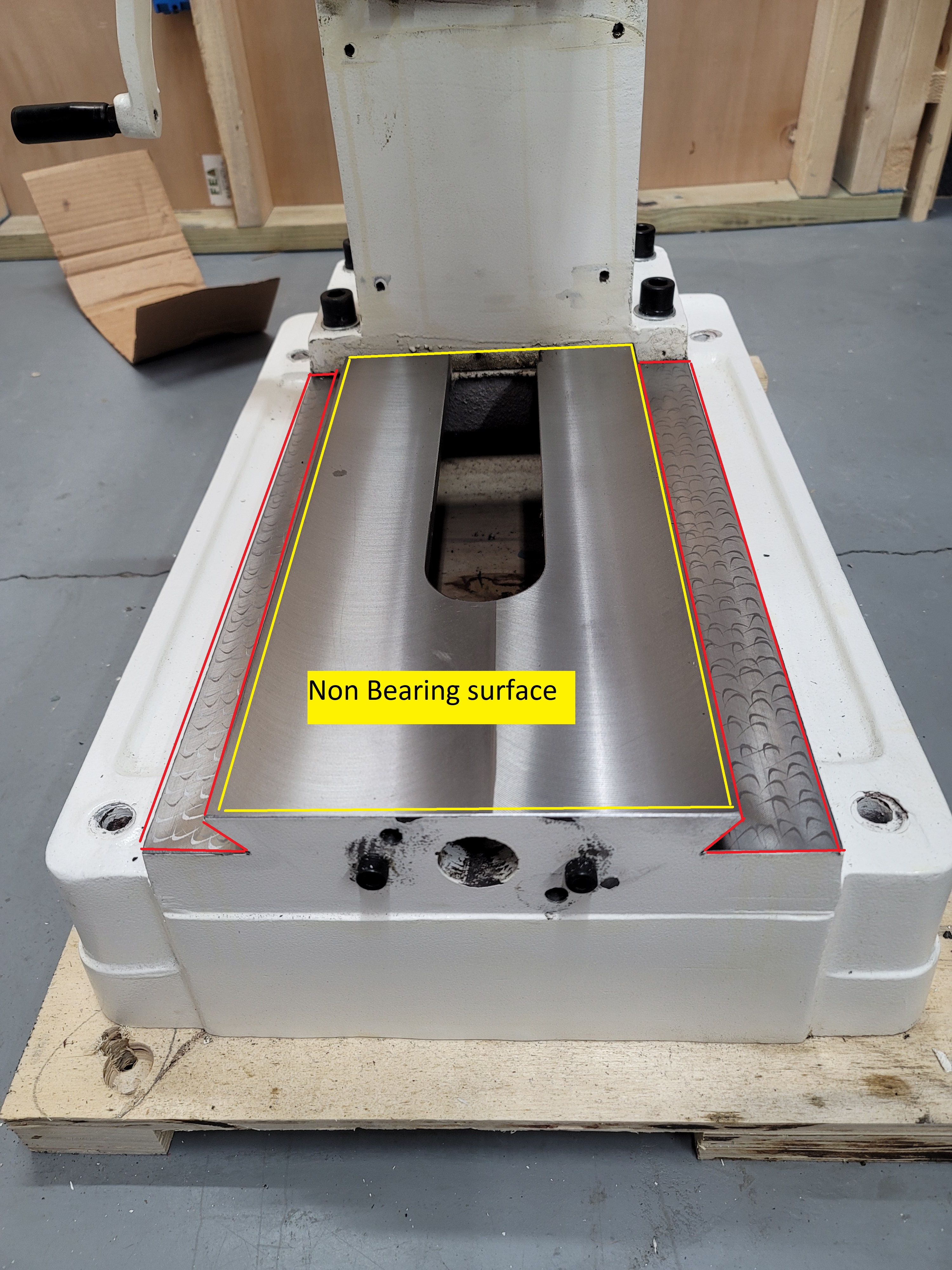

For the 932 red outlines the surfaces that come in contact with the saddle these are what we cant to keep lubricated, Z axis is the same story just vertical the large flat top of the dovetail just needs to be oiled to prevent rust.

Lubricant: ISO 68 Oil (Mobile Vactra 2, Mobil Vacuoline 1409 is the original Vactra 2 formula that has tackifiers, Z can use a heavier oil to stick to the vert surface if desired/available)

QTY: thin coat to the ways

Frequency: check/apply every day before use as needed.

Application Method: Brush/fingers for vertical surfaces? hit dovetail sloped surfaces /gib and bearing faces, run table in/out left right make sure all areas covered

Purpose: Lubricates ways for smooth operation and to avoid stiction between two flat metal surfaces will help prevent stuttering and ensure even smooth table movement.

Location: gearbox (for geared heads only)

Lubricant: ISO 68 Oil (Mobile DTE26), SAE 80W90 auto gear oil

QTY: ~3QT

Frequency: Annually (should consider a change after a break in period if new)

Application Method: Oil change, drain from bottom fill from top see manual)

Purpose: keeps the gears lubricated and cool so that the motor can turn the spindle smoothly/efficiently

Location: PDF Mech Box (for PDF Models only) (pic borrowed from this thread https://www.hobby-machinist.com/threads/lubrication-questions-for-pm45-pdf.15267/)

Lubricant: "Heavy Oil" assuming that would refer to a ISO 68 Oil (Mobile DTE26) but maybe heavier

QTY: couple drops

Frequency: every time you use it

Application Method: Oil can/squeeze bottle

Purpose: keeps the gears lubricated and cool so that the motor can turn the spindle smoothly/efficiently

Location: Quill feed (for NON-PDF Models only)

remove the tension knob that engages the fine downfeed, then remove key and pulling two socket head cap screws will let you remove the fine downfeed unit, sealed bearings on the worm gear shaft but wormgear can be regreased with NLGL2 grease

Lubricant: NLGL 2 grease (Super Lube NLGL 2 multi purpose synthetic grease with Syncolon)

QTY: decent slather on the gears

Frequency: Maybe initially

Application Method: grease gun/fingers/whatever you want to use

Purpose: keeps the gears lubricated for smooth quill feed only used for the fine adjustment feed

Few other generic questions to be filled in so they can be updated above

Spindle area? I know i read a drop or two of ISO 32 Oil (Mobile DTE24) along the drawbar. Spindle I think given the lack of oilers is a packed grease situation?

I noticed all the leadscrew "nuts" if that is the right terms come from the factory slathered in a grease, from all that I read leadscrews should be oiled so I assume clean and only use oil on the leadscrew and that will work its way to the interface to the nut.

"Bare metal surfaces" various spots think like the top of the head, the table a few odd spots the tops of the dovetails that are not bearing surfaces. basically I assume a thin oil coat to prevent rust, anything particular? i.e. like a mineral oil or a lighter side of oils?

I think that covers about everything that one would lubricate, like I said once I have a few answers I will work on filling in or brushing up this post. For me Ill probably just make a little spreadsheet cheat sheet and color code my lubricants. Just to keep everything nice and organized/orderly in the shop.

I have no doubt that most of this will become second nature but coming into it fresh with a mill most of the way apart I thought it was a good exercise and maybe be good info for someone else so they don't have to thumb thru a few threads on the subject.

cheers!

EDIT added some pictures and more notes

Being relatively new to working with machine tools I went looking for good info on lubricants, how/where/how often and application methods. Basically I wanted a cheat sheet so I can be sure to keep my new machine happy and running well for as long as possible. I have no problems with regular maintenance just like to have it documented.

Call me crazy but I at least thought it would be useful, and perhaps good reference for others. I will intend to keep this top post updated as some of the blanks or questions I have get filled in and add in some pictures of the given areas oilers etc.

RF 45/PM 932 series of mills. For reference the PM932V is what started this list but should apply to most all of the square column bench top type of mills of the RF45 clone family of products. Also Mobile oils referenced specifically as that is what I found conversion charts for/easy to get in manageable qty's

Location: X,Y axis ball oilers (near handles)

Lubricant: ISO 32 Oil (Mobile DTE24)

QTY: few drops/short squeeze

Frequency: every day before use.

Application Method: Oil can/squeeze bottle

Purpose: Lubricates leadscrew bearings (on x axis left side no bearings its just a bushing surface)

Location: X,Y Axis leadscrews

The large X axis leadscrew runs the length of the table can oil it via can or squeeze bottle run to one side oil and run to the other.

Y axis leadscrew only visible if you remove the rear bellow covers and move table forward apply oil and run table in and out.

Lubricant: ISO 32 Oil (Mobile DTE24)

QTY: few drops/short squeeze

Frequency: ???? weekly/monthly if you get jitters in DRO readout its time to oil them

Application Method: Oil can/squeeze bottle

Purpose: Lubricates leadscrews/ leadscrew "nut"

Location: Z Lead Screws

Lubricant: ISO 68 Oil (Mobile DTE26)

QTY: few drops/short squeeze

Frequency: ????

Application Method: Oil can/squeeze bottle

Purpose: Lubricates leadscrew bearings? (is it just the leadscrew bearings or is it supposed to work its way to lead screws as well?)

Location: Z axis "transfer gears" (gears than translate horizontal to vertical rotation)

Can access by removing bellows on the z axis or from the rear panel (on the 932V no rear panel but the large control box instead)

Lubricant: NLGL 2 grease (Super Lube NLGL 2 multi purpose synthetic grease with Syncolon), or Oil ISO 68 Oil (Mobile DTE26)

QTY: few drops/short

Frequency: ???? maybe annually if that

Application Method: grease gun, putty knife, fingers whatever works

Purpose: Lubricates the gears for the z axis handle, (still a thing even with z axis power feed the leadscrew will turn the handle shaft so its still a part interacting even if under much less loading)

Location: X,Y,Z Ways (machines with a built in one shot oiler use that instead)

X axis has ball oilers on the 932, but just a large hole that feeds into the ways Y and Z still are manual application

For the 932 red outlines the surfaces that come in contact with the saddle these are what we cant to keep lubricated, Z axis is the same story just vertical the large flat top of the dovetail just needs to be oiled to prevent rust.

Lubricant: ISO 68 Oil (

QTY: thin coat to the ways

Frequency: check/apply every day before use as needed.

Application Method: Brush/fingers for vertical surfaces? hit dovetail sloped surfaces /gib and bearing faces, run table in/out left right make sure all areas covered

Purpose: Lubricates ways for smooth operation and to avoid stiction between two flat metal surfaces will help prevent stuttering and ensure even smooth table movement.

Location: gearbox (for geared heads only)

Lubricant: ISO 68 Oil (Mobile DTE26), SAE 80W90 auto gear oil

QTY: ~3QT

Frequency: Annually (should consider a change after a break in period if new)

Application Method: Oil change, drain from bottom fill from top see manual)

Purpose: keeps the gears lubricated and cool so that the motor can turn the spindle smoothly/efficiently

Location: PDF Mech Box (for PDF Models only) (pic borrowed from this thread https://www.hobby-machinist.com/threads/lubrication-questions-for-pm45-pdf.15267/)

Lubricant: "Heavy Oil" assuming that would refer to a ISO 68 Oil (Mobile DTE26) but maybe heavier

QTY: couple drops

Frequency: every time you use it

Application Method: Oil can/squeeze bottle

Purpose: keeps the gears lubricated and cool so that the motor can turn the spindle smoothly/efficiently

Location: Quill feed (for NON-PDF Models only)

remove the tension knob that engages the fine downfeed, then remove key and pulling two socket head cap screws will let you remove the fine downfeed unit, sealed bearings on the worm gear shaft but wormgear can be regreased with NLGL2 grease

Lubricant: NLGL 2 grease (Super Lube NLGL 2 multi purpose synthetic grease with Syncolon)

QTY: decent slather on the gears

Frequency: Maybe initially

Application Method: grease gun/fingers/whatever you want to use

Purpose: keeps the gears lubricated for smooth quill feed only used for the fine adjustment feed

Few other generic questions to be filled in so they can be updated above

Spindle area? I know i read a drop or two of ISO 32 Oil (Mobile DTE24) along the drawbar. Spindle I think given the lack of oilers is a packed grease situation?

I noticed all the leadscrew "nuts" if that is the right terms come from the factory slathered in a grease, from all that I read leadscrews should be oiled so I assume clean and only use oil on the leadscrew and that will work its way to the interface to the nut.

"Bare metal surfaces" various spots think like the top of the head, the table a few odd spots the tops of the dovetails that are not bearing surfaces. basically I assume a thin oil coat to prevent rust, anything particular? i.e. like a mineral oil or a lighter side of oils?

I think that covers about everything that one would lubricate, like I said once I have a few answers I will work on filling in or brushing up this post. For me Ill probably just make a little spreadsheet cheat sheet and color code my lubricants. Just to keep everything nice and organized/orderly in the shop.

I have no doubt that most of this will become second nature but coming into it fresh with a mill most of the way apart I thought it was a good exercise and maybe be good info for someone else so they don't have to thumb thru a few threads on the subject.

cheers!

EDIT added some pictures and more notes

Last edited: