- Joined

- Jan 25, 2022

- Messages

- 110

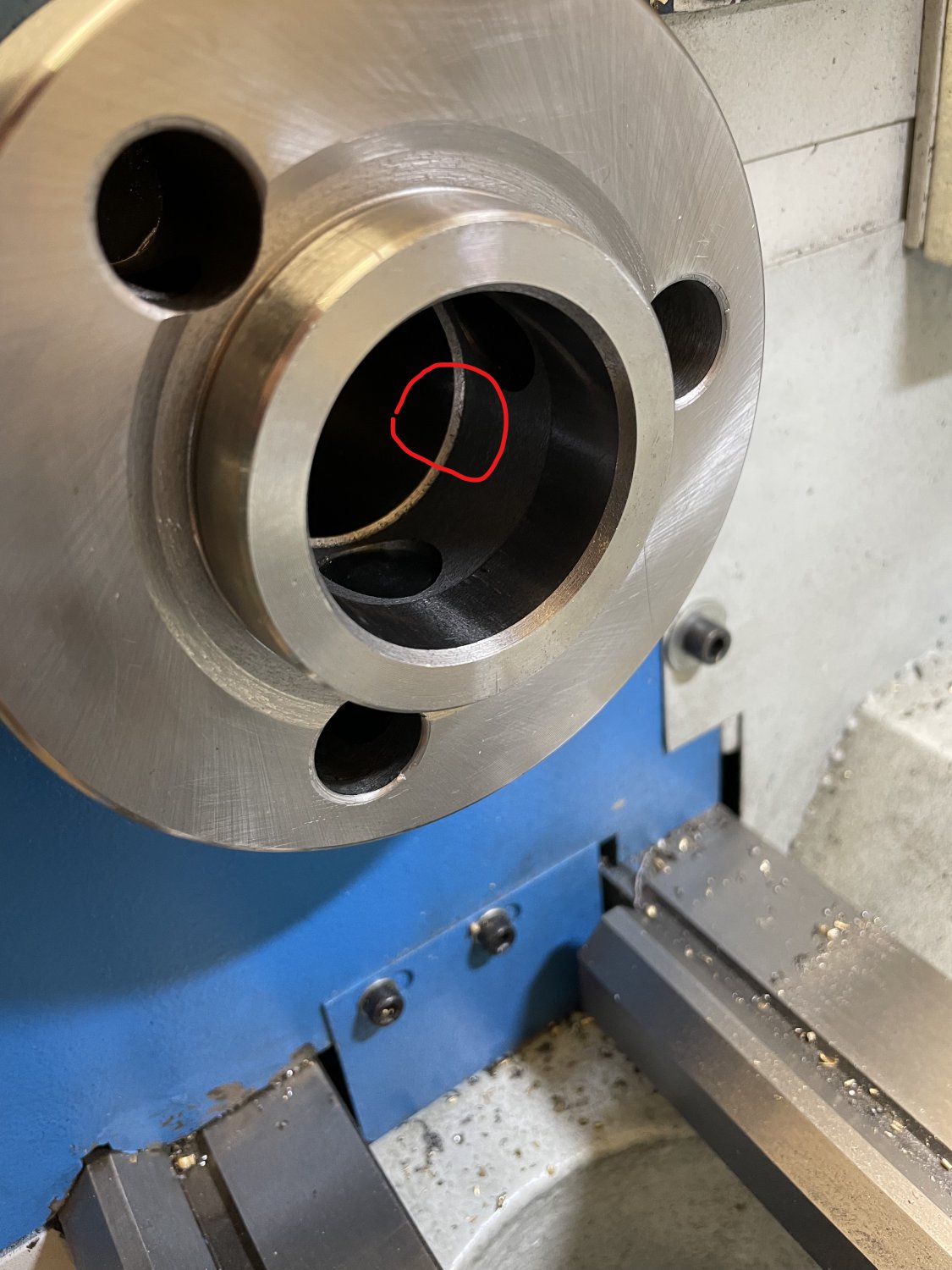

Was trying to align the tailstock spindle. Had an MT3 dead center, so I inserted an MT5/MT3 adapter in the headstock spindle, but it wouldn't seat onto the spindle taper.

I found that the adapter was bearing on a ledge further in, limiting how far in the adapter could move.

I was able to machine off that ledge, matching the MT5 spindle taper, so the adapter now seats properly. It was a challenge, as that was the limit of my 1/2" boring bar extension. Lots of chatter, and not great finish. But it worked.

Not sure what is wrong here. Spindle taper too wide, that ledge not machined? I am sure that a MT5 dead center would have a similar problem -- if not worse, as they are longer than the adapter.

Anyone seen this problem?

Thanks

I found that the adapter was bearing on a ledge further in, limiting how far in the adapter could move.

I was able to machine off that ledge, matching the MT5 spindle taper, so the adapter now seats properly. It was a challenge, as that was the limit of my 1/2" boring bar extension. Lots of chatter, and not great finish. But it worked.

Not sure what is wrong here. Spindle taper too wide, that ledge not machined? I am sure that a MT5 dead center would have a similar problem -- if not worse, as they are longer than the adapter.

Anyone seen this problem?

Thanks