Trying to gauge folks opinions of these two mills. Just a hobbyist...never have had a mill before. Don't intend to be doing production. Eventually would like to CNC whatever one I do get, but realistically with the purchase of one of these that will be 1-2 years down the road. Would like to use whichever mill in manual mode for a while to 'get the hang' of it. Thoughts?

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

PM30 or PM-932?

- Thread starter dlinva

- Start date

- Joined

- May 19, 2014

- Messages

- 70

I chose the 932 primarily for weight/stiffness, 530 lbs. vs. 850 lbs. Good luck!

I was in a similar situation and chose the PM932. I didn't get the power downfeed and can't say that it has bothered me not to have it. I have been happy with it for anything I have needed to do with it. The only thin Ig did was build a base to raise it up. The working height for me was too low as it came. I can take a pic of the base I had built if you decide to go that route.

I also added the DRO after I got it. Easier to get it installed to start, but wasn't terribly hard either.

I also added the DRO after I got it. Easier to get it installed to start, but wasn't terribly hard either.

Weight/stiffness is a big deal. My issue is that my shop is in my walkout basement. Have to come in through a normal width man door from the outside and then through another man door into the shop area. Thinking that I could use an engine hoist in the basement but that some disassembly will be required immediately outside the basement. Would like to see your base if you wouldn't mind sharing. I have also been thinking about raising whichever mill I get up some. I am 6' and really don't like to spend a lot of time stooped over. Any issues with the 932 that you have experienced? Any regrets? Thanks!

- Joined

- Nov 28, 2020

- Messages

- 93

I just got a PM-30MV, and with the 'welded sheet metal' stand offered by PM, it was too low. I'm 6' 1". I ended up building a 5" platform to raise it up, and that helps, but it could even be a few inches higher for my liking. .

Its a heavy machine, even moving it around with a 2-ton engine hoist. I imagine a PM-932 at twice the weight could be a challenge to get through two small doors. I would assume some disassembly will be required, unless you can get the engine hoist to roll through the door while lifting the mill. Mine is in my garage with lots of room to move around with the hoist.

Its a heavy machine, even moving it around with a 2-ton engine hoist. I imagine a PM-932 at twice the weight could be a challenge to get through two small doors. I would assume some disassembly will be required, unless you can get the engine hoist to roll through the door while lifting the mill. Mine is in my garage with lots of room to move around with the hoist.

- Joined

- May 19, 2014

- Messages

- 70

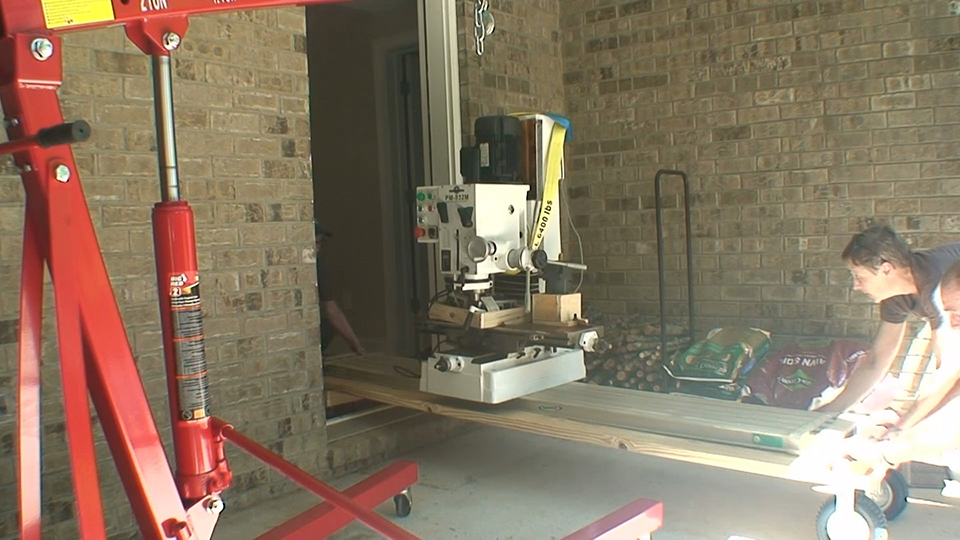

THE MOVE

(1) Pull mill in enough to strap around head.

(2) Hoist into truck move to back of house

(3) 2Ton lift won’t go or reach through door. Built slide.

(4) Roll into room.

(5) Remove mill from slide.

I have a G0704 Grizzly mill which was my first. I could actually see it flex some when milling. That’s why I wanted a heavier mill. Additionally the extra 3” on the Z-axis of the PM932 over the PM30 comes in very handy when using a boring bar and/or tilt table. I considered the PM40 but it would not fit through my door without disassembly. No regrets on the PM932.

As far as working height, I’m 5’3” no problem here…

(1) Pull mill in enough to strap around head.

(2) Hoist into truck move to back of house

(3) 2Ton lift won’t go or reach through door. Built slide.

(4) Roll into room.

(5) Remove mill from slide.

I have a G0704 Grizzly mill which was my first. I could actually see it flex some when milling. That’s why I wanted a heavier mill. Additionally the extra 3” on the Z-axis of the PM932 over the PM30 comes in very handy when using a boring bar and/or tilt table. I considered the PM40 but it would not fit through my door without disassembly. No regrets on the PM932.

As far as working height, I’m 5’3” no problem here…

Here is mine with the base. The base is made out of 4x4x.25" square tube. I drilled a hole in the bottom and turned some round stock to have a head on it, tapped it, and welded them on for the levelers. I think I drilled through completely and used bolts to fasten the base to the stand. The dimensions of the stand is shown in the last pic. It makes it much more stable and easy to level.

- Joined

- Jan 26, 2021

- Messages

- 345

That base looks nice. Just like it grew there.