- Joined

- Dec 28, 2018

- Messages

- 64

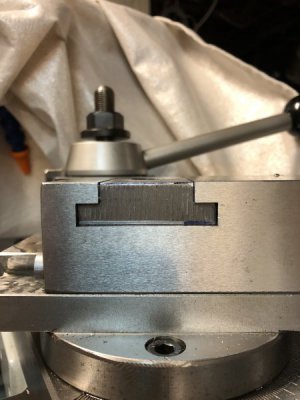

I had bought a Aloris Quick change post before I ordered my lathe so I had to make my Cross slide T-nut out of the blank that came with it...

BTW if you order a lathe from Matt (PM) and you happen to buy the Aloris from they you get a pre-made T-bolt for it so you don’t have to make your own... hindsite is 20/20...

Anyway - I work a couple of jobs so setting up my lathe and mill has taken a lot longer for me than most you guys... Mill is done, leveled and cranking out stuff.

The lathe - I have the VFD up and running, and am doing the spider this week, and will do the anchors very soon.

A few pictures of the T-Nut I made out of the Aloris blank just for fun..

I used a HSS 3/8” end mill to cut down the side, and the T slot or step in the sides, then I used a HSS fly cutter to take a little off the top, I should have shown the finishing top fly cut, the one in the picture is the last fitting check so it looks rough..

BTW if you order a lathe from Matt (PM) and you happen to buy the Aloris from they you get a pre-made T-bolt for it so you don’t have to make your own... hindsite is 20/20...

Anyway - I work a couple of jobs so setting up my lathe and mill has taken a lot longer for me than most you guys... Mill is done, leveled and cranking out stuff.

The lathe - I have the VFD up and running, and am doing the spider this week, and will do the anchors very soon.

A few pictures of the T-Nut I made out of the Aloris blank just for fun..

I used a HSS 3/8” end mill to cut down the side, and the T slot or step in the sides, then I used a HSS fly cutter to take a little off the top, I should have shown the finishing top fly cut, the one in the picture is the last fitting check so it looks rough..