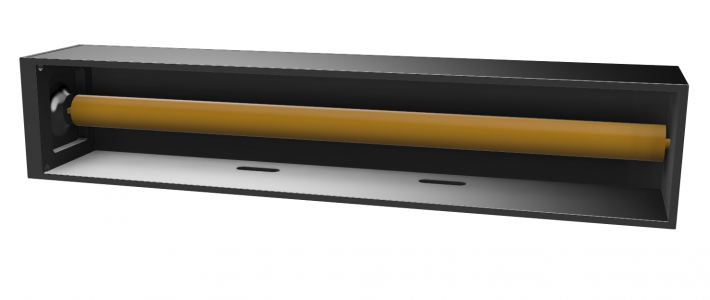

Finally fixed the floppy Z axis way cover. I was going to just purchase bellows from McMaster like others have done but decided to go another route. I picked up a $11 roll up blind off amazon cut it down and riveted the rubber to it. I then 3d printed a holder and clamp for the bottom and y axis. Works great.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

PM728 $11 Way cover fix

- Thread starter GB21

- Start date

- Joined

- Jan 26, 2021

- Messages

- 344

That certainly works!

This is the roller blind I used https://www.amazon.com/dp/B0716TQLQN?psc=1&ref=ppx_yo2_dt_b_product_details

I am sure just about any of them will work. Just pop off the "stop pawls" and cut the tube to length. The hardest part is figuring out how to mount the spring tube. I might make a aluminum case to replace the printed plastic but its working well for now.

I am sure just about any of them will work. Just pop off the "stop pawls" and cut the tube to length. The hardest part is figuring out how to mount the spring tube. I might make a aluminum case to replace the printed plastic but its working well for now.

Attachments

I hate trying to clean the debris and oil out the folds in mine. I have a 940M.

I like your approach as long as the spring roller is not in the way. It should fit as it is probably smaller than the normal folds. I have a couple of very old blinds where the original paper is gone. I was thinking about replacing the paper with Teflon sheet rather than rubber. They sell thin teflon that is used for thermal transfer or to line an oven or bake sheet liners to catch the grease, oils or preventing sticking. It would clean easily and be resistant to oils. It is also high temperature. It comes in various lengths but is probably made in very long rolls. Here is a 24" version. https://www.amazon.com/Stick-Teflon...Y,B092M4T5LW,B08T7ZPW8L,B07F8TZZ4N,B074S8SNZN

It would be nice to find a little thicker version. It exists as I have some old "pure" Teflon sheets, but it is too small for this application and I no longer know where it came from. It is tough, slick stuff.

I agree with your move to replace the polyester/vinyl that comes with the shade. Probably does not hold up to oils very long and might break due to debris hitting it.

I suppose one could also use a very thin, fine stainless screen.... think filter paper. I have a nice piece of it,that was in the house when I purchased it, but I have no idea where it came from originally!

Your approach might also work to keep my lathe ways clean!

Dave

I like your approach as long as the spring roller is not in the way. It should fit as it is probably smaller than the normal folds. I have a couple of very old blinds where the original paper is gone. I was thinking about replacing the paper with Teflon sheet rather than rubber. They sell thin teflon that is used for thermal transfer or to line an oven or bake sheet liners to catch the grease, oils or preventing sticking. It would clean easily and be resistant to oils. It is also high temperature. It comes in various lengths but is probably made in very long rolls. Here is a 24" version. https://www.amazon.com/Stick-Teflon...Y,B092M4T5LW,B08T7ZPW8L,B07F8TZZ4N,B074S8SNZN

It would be nice to find a little thicker version. It exists as I have some old "pure" Teflon sheets, but it is too small for this application and I no longer know where it came from. It is tough, slick stuff.

I agree with your move to replace the polyester/vinyl that comes with the shade. Probably does not hold up to oils very long and might break due to debris hitting it.

I suppose one could also use a very thin, fine stainless screen.... think filter paper. I have a nice piece of it,that was in the house when I purchased it, but I have no idea where it came from originally!

Your approach might also work to keep my lathe ways clean!

Dave

I thought the bellows on the 940 looked decent. Below is a video of what I was dealing with. Sticking my arm behind the spindle almost every tool change. When moving the x axis it would also scoop the chips onto the ways and ballscrew.

That is the first time I have ever seen that teflon sheet. I think its a great idea it would keep the weight down and more importantly decrease the size of the roll. With the rubber rolled up the box needs to be about 2" for it to fit. As far as being out of the way It is still above the spindle so I have plenty of clearance.

That is the first time I have ever seen that teflon sheet. I think its a great idea it would keep the weight down and more importantly decrease the size of the roll. With the rubber rolled up the box needs to be about 2" for it to fit. As far as being out of the way It is still above the spindle so I have plenty of clearance.

Wow, both attachment images are pretty ugly and a similar problem... in the way!

Yes, the 940 has bellows that so far have held up ok. No holes... However, the end clamping mechanism is pretty wimpy. I just get tired of trying to clean out the folds....especially the oil. Occasionally I need to cut a non-metal material (plastic, wood, etc) and when these fine debris get in the oil they stick and built up.

Yes, the 940 has bellows that so far have held up ok. No holes... However, the end clamping mechanism is pretty wimpy. I just get tired of trying to clean out the folds....especially the oil. Occasionally I need to cut a non-metal material (plastic, wood, etc) and when these fine debris get in the oil they stick and built up.