- Joined

- Feb 17, 2013

- Messages

- 4,407

Searching for a good way to peel the paper from some polycarbonate sheet (brand names like Lexan, Hyzod, Makrolon, Lupilon, Calibre, etc.), I ran across several posts (on other forums) that claimed that polycarbonate would be attacked/weakened/ruined by oils. Among the discussions was a caution about making machine guards of polycarbonate.

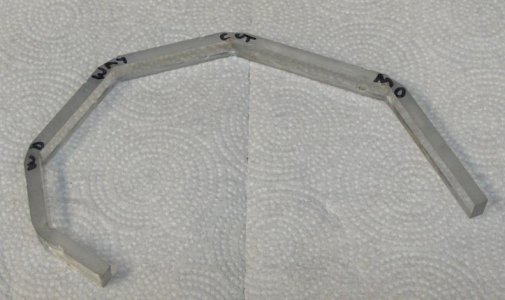

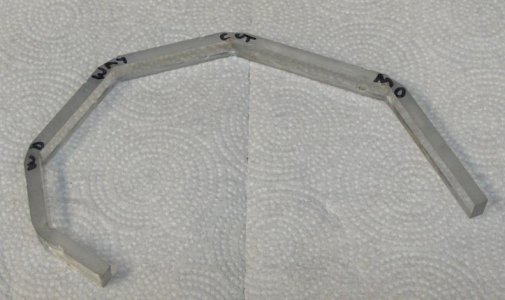

I decided to do a quick-and-dirty test. Took a 1/4" x ~3/8" strip of the material and applied dabs of WD-40, way oil, black (sulfur) cutting oil, and drug store mineral oil to various places along one side. Waited 24 hours. Then I cleaned the oil off and tried bending/breaking each of the oiled places. To do this, I held the strip in my vise and used a 7/16" box end wrench to give each point a ~45 degree kink. The oiled areas were on the outside of the bend, so they got get tensile stress. I also tested an un-oiled section of the bar.

Results - Each of the bends produced a flattened, stretched area on the outside (oiled face) of the bend, but there were no signs of any kind of failure at any of them. All the bends (oiled or not) seemed to take about the same amount of force.

Initial conclusion - oils don't seem to affect polycarbonate. I realize that 24 hours would not be long enough for oil to diffuse deeply into the plastic, but I would have expected some kind of change to show up in the bend test.

Does anybody have further information or direct experience?

I decided to do a quick-and-dirty test. Took a 1/4" x ~3/8" strip of the material and applied dabs of WD-40, way oil, black (sulfur) cutting oil, and drug store mineral oil to various places along one side. Waited 24 hours. Then I cleaned the oil off and tried bending/breaking each of the oiled places. To do this, I held the strip in my vise and used a 7/16" box end wrench to give each point a ~45 degree kink. The oiled areas were on the outside of the bend, so they got get tensile stress. I also tested an un-oiled section of the bar.

Results - Each of the bends produced a flattened, stretched area on the outside (oiled face) of the bend, but there were no signs of any kind of failure at any of them. All the bends (oiled or not) seemed to take about the same amount of force.

Initial conclusion - oils don't seem to affect polycarbonate. I realize that 24 hours would not be long enough for oil to diffuse deeply into the plastic, but I would have expected some kind of change to show up in the bend test.

Does anybody have further information or direct experience?