-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Poor surface finish

- Thread starter Nutfarmer

- Start date

- Joined

- Oct 11, 2016

- Messages

- 3,866

The guy who taught me surface grinding used a 45 year old point that was flat. the plateau was bigger than .125 around. It still dressed the wheels properly. Mind you he had 60 years of grinding experience, and he wasn't open about every trick he used.....

New diamonds are pretty cheap, so get a new one and see.

New diamonds are pretty cheap, so get a new one and see.

- Joined

- Jun 7, 2019

- Messages

- 360

0.200” step over is a lot for dry grinding softer steel. I finish with a 0.01” step over. Sounds like a new diamond is in order too. Listen to the wheel while grinding, the sound can tell you about the dressing. experiment with speed too.

Recently added flood coolant to my grinder, what a huge improvement. If the machine can handle it it’s a great, if flood coolant isn’t an option, try a mister. See if you can find a copy of Norton’s grinding booklet. Great info. just my 2Cents

Recently added flood coolant to my grinder, what a huge improvement. If the machine can handle it it’s a great, if flood coolant isn’t an option, try a mister. See if you can find a copy of Norton’s grinding booklet. Great info. just my 2Cents

- Joined

- Jun 7, 2019

- Messages

- 360

There’s a copy listed on Amazon.

A Handbook on Tool Room Grinding Paperback – January 1, 1957

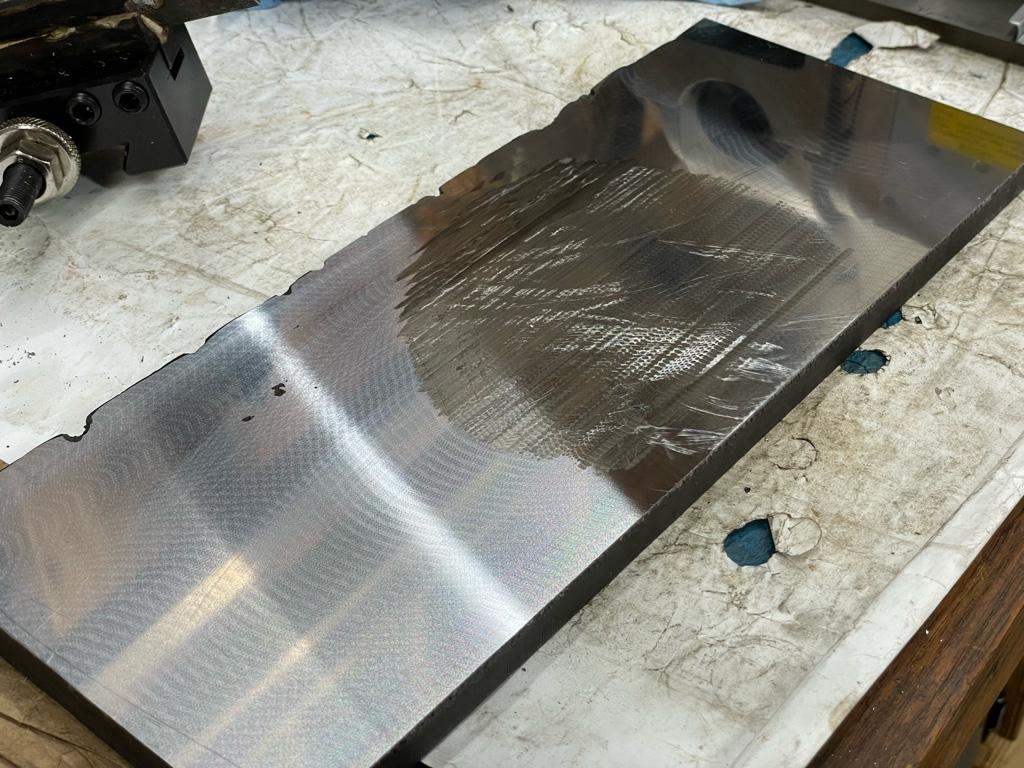

To me it looks like a dressing problem. It looks very similar to when I touched a 46I wheel with a hand dressing stone, then ground a piece of mild steel. It burned the surface and gave a horrible finish. I found it interesting to see the wheel progress worse and worse as it traversed:

That operation used spray coolant, and it wasn’t spraying very well.

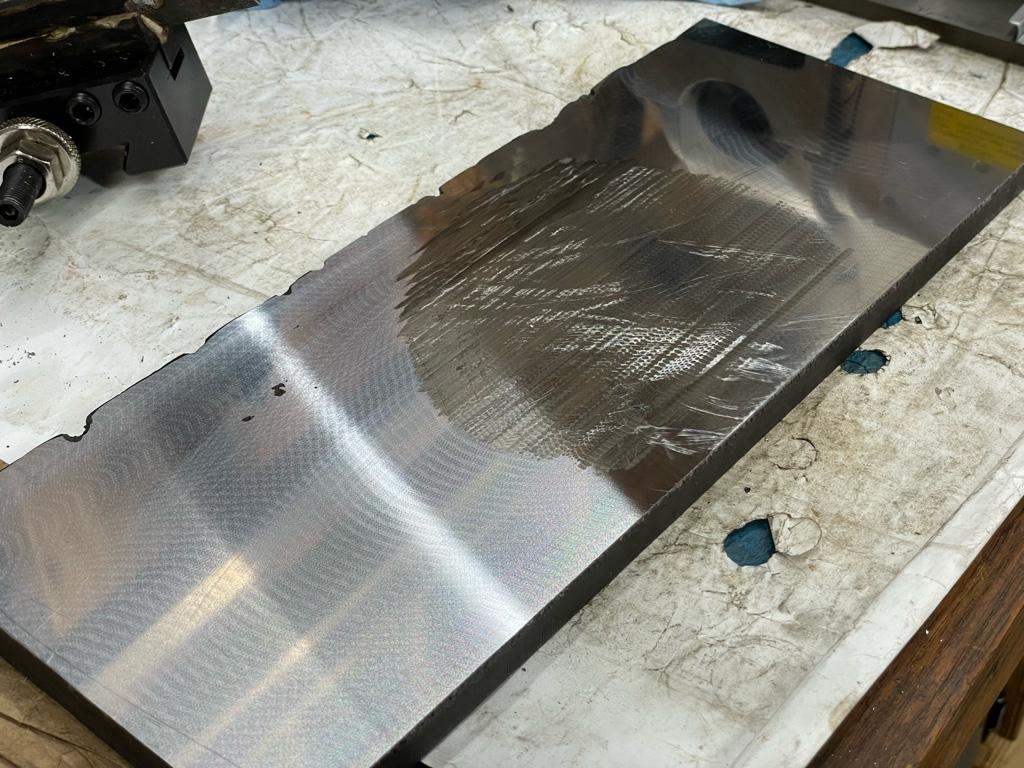

I later partially redid it with a properly dressed 46H wheel. The plate isn’t very flat and showed some patterning but the surface is quite smooth and nothing like the first try.

I also used spray coolant for this one, though it was spraying better.

I have tons to learn but thought you might find it interesting to see the surface left by my poorly dressed wheel. This is the hand dresser I used (I believe it may be appropriate for opening a resin-bonded diamond wheel): https://www.mcmaster.com/4520A2

That operation used spray coolant, and it wasn’t spraying very well.

I later partially redid it with a properly dressed 46H wheel. The plate isn’t very flat and showed some patterning but the surface is quite smooth and nothing like the first try.

I also used spray coolant for this one, though it was spraying better.

I have tons to learn but thought you might find it interesting to see the surface left by my poorly dressed wheel. This is the hand dresser I used (I believe it may be appropriate for opening a resin-bonded diamond wheel): https://www.mcmaster.com/4520A2

- Joined

- Jun 7, 2019

- Messages

- 360

When the wheel isn’t cutting well its generating a lot of heat. Could be dressing, but …. You can see where the center swelled the first time and cooled leaving a dip the second time. That looks like a big piece for dry grinding. Try very light cuts at a fast traverse speed, small step over. It has to stay cool to the touch or it won’t be flat when it cools.

You can see where the center swelled the first time and cooled leaving a dip the second time. That looks like a big piece for dry grinding.

My piece wasn’t dry, it was with spray coolant both times and was not hot. The first session was with very small stepover but pretty big downfeed (like .002-.003”). I have ground other, thinner pieces without a problem. The first session here with the hand dresser stick is the only time I have seen anything like that result.

When you say hand dressing the wheel do you mean holding a dresser in your hand and dressing the wheel? If so you’d get a terrible dressing on the wheel. Diamond point needs to be stationary.

I also see your diamond is standing straight up which would wear the diamond to a flat. I think a better design is angling the diamond 15-20*. I always spin my diamond so it’s cutting on the facets of the diamond. Which helps with longevity of diamond.

Try finish passes in the tenths not thousandths.

I also see your diamond is standing straight up which would wear the diamond to a flat. I think a better design is angling the diamond 15-20*. I always spin my diamond so it’s cutting on the facets of the diamond. Which helps with longevity of diamond.

Try finish passes in the tenths not thousandths.