- Joined

- Dec 31, 2013

- Messages

- 327

If you make or repair stuff, it doesn't take long to amass quite a collection of small parts and hardware. While it can be quite satisfying to dig through your stash and find that needed item to finish a project, it can also be twice as discouraging to know you have it and can't find it. It sucks having to stop what you are doing and waste an hour going to the hardware store or wait days (or weeks) for a mail order to arrive.

I've tried various organizers, baby food jars and open bins and so far the best thing I've found is the portable parts storage case. This is a nice one from Harbor Freight, available in two different depths:

https://www.harborfreight.com/19-bin-portable-parts-storage-case-93928.html

Also Sortimo makes a "Cadillac" version shown here:

http://www.sortimo-shop.us/product-p/51011476.htm

I like these cases because they are portable, so you can take the whole kit to the job. The bins are removable, so you can customize a case for a specific task, like using a bunch of little bins for fuses. If you have a 3D printer it's also easy to make you own custom bins. The lid and latches keep the parts inside the bins and the bugs and dirt out.

While I've never seen one in person, I've heard good things about the Sortimo case and it certainly looks very nice. Unfortunately, they are around $60 while the HF version shown above can be had for $6. I went with the HF version and haven't had any real issues.

After awhile I had 8 or so cases, and while they stack nice, invariable the one you want is at the bottom of the stack. I also wanted to reclaim the precious shelf space consumed by the storage cases. What I needed was a separate, dedicated shelving unit to store the cases. I had a spot for one, but since the shop is at 125% capacity the shelf needed to roll on casters so it could move easily if necessary. It also needed to be fairly easy to build, since I'm not that great a fabricator and don't even have a dedicated welding area. So, after a bit of time at the scratch pad, a simple cart was devised that could be made from 1" square tubing and angle iron.

Starting on the base, using a little Everlast 120V MIG with fluxcore wire and a HF TV Tray welding table.

The little 4x6 bandsaw was quite busy that day cutting tubing and angle iron as I bought longer raw stock than I normally obtain to save a little money. For the bandsaw cutting stop, I had to turn down a longer bar because it was metric. The whole cutting operation went quite well, as while one piece was cutting I was deburring another at the 1" Kalamazoo sander.

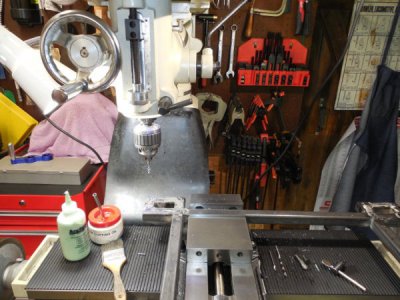

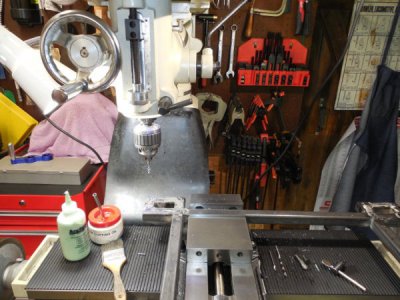

The casters were place outside of the main frame for maximum stability. The last thing you want is a unstable tower of storage cases prone to tipping over. Here I am drilling & power tapping 1/4-20 holes to mount the casters.

Tacking on some more pieces and seeing how things are working out. There was some on-the-fly design changes as sometimes my chicken-CAD drawings don't work out completely.

The completed cart, front view. There are 4 double-depth cases at the bottom and 13 regular cases.

Side View.

Top view. Only the sides of the cases sit on the angle iron but they seem to be sturdy enough that I don't think they will sag. A flat bar runs down the back of the cart to function as a stop. Once the cart was parked at it's usual location, I realized I could squeeze in one more case so I added some flat bar for a shelf on the top.

Bottom view. The casters are from Home Depot and they are very nice because they lock the wheel AND rotation. For the double-depth cases, I ran some flat bar horizontally across the bottom for sag support because these cases can be a great deal heavier.

And that was my big fabrication project for the summer. It's still very much a work in progress as I need to get the label maker out to mark cases and sort more parts. Sometimes it's challenging to group various parts in one case in a logical manner. Right now, I even have a few empty cases but I'm sure that won't last long.

I've tried various organizers, baby food jars and open bins and so far the best thing I've found is the portable parts storage case. This is a nice one from Harbor Freight, available in two different depths:

https://www.harborfreight.com/19-bin-portable-parts-storage-case-93928.html

Also Sortimo makes a "Cadillac" version shown here:

http://www.sortimo-shop.us/product-p/51011476.htm

I like these cases because they are portable, so you can take the whole kit to the job. The bins are removable, so you can customize a case for a specific task, like using a bunch of little bins for fuses. If you have a 3D printer it's also easy to make you own custom bins. The lid and latches keep the parts inside the bins and the bugs and dirt out.

While I've never seen one in person, I've heard good things about the Sortimo case and it certainly looks very nice. Unfortunately, they are around $60 while the HF version shown above can be had for $6. I went with the HF version and haven't had any real issues.

After awhile I had 8 or so cases, and while they stack nice, invariable the one you want is at the bottom of the stack. I also wanted to reclaim the precious shelf space consumed by the storage cases. What I needed was a separate, dedicated shelving unit to store the cases. I had a spot for one, but since the shop is at 125% capacity the shelf needed to roll on casters so it could move easily if necessary. It also needed to be fairly easy to build, since I'm not that great a fabricator and don't even have a dedicated welding area. So, after a bit of time at the scratch pad, a simple cart was devised that could be made from 1" square tubing and angle iron.

Starting on the base, using a little Everlast 120V MIG with fluxcore wire and a HF TV Tray welding table.

The little 4x6 bandsaw was quite busy that day cutting tubing and angle iron as I bought longer raw stock than I normally obtain to save a little money. For the bandsaw cutting stop, I had to turn down a longer bar because it was metric. The whole cutting operation went quite well, as while one piece was cutting I was deburring another at the 1" Kalamazoo sander.

The casters were place outside of the main frame for maximum stability. The last thing you want is a unstable tower of storage cases prone to tipping over. Here I am drilling & power tapping 1/4-20 holes to mount the casters.

Tacking on some more pieces and seeing how things are working out. There was some on-the-fly design changes as sometimes my chicken-CAD drawings don't work out completely.

The completed cart, front view. There are 4 double-depth cases at the bottom and 13 regular cases.

Side View.

Top view. Only the sides of the cases sit on the angle iron but they seem to be sturdy enough that I don't think they will sag. A flat bar runs down the back of the cart to function as a stop. Once the cart was parked at it's usual location, I realized I could squeeze in one more case so I added some flat bar for a shelf on the top.

Bottom view. The casters are from Home Depot and they are very nice because they lock the wheel AND rotation. For the double-depth cases, I ran some flat bar horizontally across the bottom for sag support because these cases can be a great deal heavier.

And that was my big fabrication project for the summer. It's still very much a work in progress as I need to get the label maker out to mark cases and sort more parts. Sometimes it's challenging to group various parts in one case in a logical manner. Right now, I even have a few empty cases but I'm sure that won't last long.