-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

POTD- PROJECT OF THE DAY: What Did You Make In Your Shop Today?

- Thread starter wachuko

- Start date

- Joined

- Dec 20, 2021

- Messages

- 897

Headlights are polycarbonate now, IIRC. I don't think that acetone on polycarbonate is good.As a product available in the EU, acetone makes the most sense. It seems like a safe enough way to do it considering the hazards using hot acetone entails. I'd certainly give it a shot. Frosty headlights on your baby can be a real tear jerker.

Edit. Some references are acetone. Hmmm. Usually that's bad with polycarbonate. I'm starting to smell snakeoil salesman stuff here...

Anyone have an MSDS for the stuff?

Last edited:

- Joined

- Apr 23, 2018

- Messages

- 6,610

These plastics are softened by acetone:Headlights are polycarbonate now, IIRC. I don't think that acetone on polycarbonate is good.

It must be something that's in a volatile solvent, and leaves the hot bottle with the solvent. And stays behind after the solvent 'goes away'. But guessing that acetone might not be it because acetone on polycarbonate is bad.

Edit. Some references are acetone. Hmmm. Usually that's bad with polycarbonate. I'm starting to smell snakeoil salesman stuff here...

Anyone have an MSDS for the stuff?

- PVDF

- Polycarbonate

- Polysulfone

- Cast Acrylic

- PVC

- CPVC

- Joined

- Nov 23, 2014

- Messages

- 2,611

POTD was a clean up job on my Clausing 5418 lathe. I wrapped up the first run of reproduction Erector set part number 'B2' wooden-handled screwdrivers which made quite a mess.

I started by vacuuming up the major debris, wiped everything down with a rag, then a second vacuuming followed by a second wipe-down. On the plus side, I found some tools in the chip pan that had disappeared.

Thanks for looking, Bruce

I started by vacuuming up the major debris, wiped everything down with a rag, then a second vacuuming followed by a second wipe-down. On the plus side, I found some tools in the chip pan that had disappeared.

Thanks for looking, Bruce

Last edited:

- Joined

- Oct 5, 2010

- Messages

- 1,044

I would be very careful using Acetone on plastic or any surfaces. Over the years I have totally ruined numerous plastic items by just exposing them to drops of acetone. It is pretty reactive stuff. Test carefully prior to using. Reaction times vary greatly.As a product available in the EU, acetone makes the most sense. It seems like a safe enough way to do it considering the hazards using hot acetone entails. I'd certainly give it a shot. Frosty headlights on your baby can be a real tear jerker.

Last edited:

- Joined

- Nov 25, 2015

- Messages

- 8,415

so you are not putting it on with a brush, you are using the vapor to re-melt the surface of the polycarbonate and smooth it over.Headlights are polycarbonate now, IIRC. I don't think that acetone on polycarbonate is good.

It must be something that's in a volatile solvent, and leaves the hot bottle with the solvent. And stays behind after the solvent 'goes away'. But guessing that acetone might not be it because acetone on polycarbonate is bad.

Edit. Some references are acetone. Hmmm. Usually that's bad with polycarbonate. I'm starting to smell snakeoil salesman stuff here...

Anyone have an MSDS for the stuff?

You can use a propane torch on acrylic to make the edge like glass. So it makes sense that the acetone heated vapor will do the same.

- Joined

- Dec 20, 2021

- Messages

- 897

From what I've read, acetone doesn't melt polycarbonate.so you are not putting it on with a brush, you are using the vapor to re-melt the surface of the polycarbonate and smooth it over.

It does damage it by entering the surface when exposed, and leaving pores when it dries off. But maybe the acetone is exposed for such a short period of time it doesn't matter.

I'm wondering if this is more like spray paint, where the solvents allow the paint to be carried to the target, then evaporate.

Ads for this stuff refer to it as a polymer. Not sure what else they're doing.

Half wondering if it's cyanoacrylate in acetone or something simple like that. (Super glue was first developed as an optical lense material, IIRC.).

Don't know. It's an interesting process. Not sure I'd want to be exposed to it until I know what's in it, tho...

- Joined

- Apr 23, 2018

- Messages

- 6,610

I don't think there's any polymer, unless you consider the fact that acetone is a building block for plastic components methyl methacrylate and bisphenol A, both of which are in polycarbonate.

This stuff is as chinese as Mu Shu, so there's no SDS or safety info.

The best I could come up with is a mixture for a spray clarifier minus the propellants:

Acetone, butyl acetate, and methyl isobutyl ketone solvents with a propylene glycol methyl ether acetate or something similar with a lower BP as a surfactant.

I found mixed results with pure acetone on the web, it seems to me that surface prep and wet sanding the factory coatings is the key. Lots of confounding info with very little facts to support it out there. No SDS of course, it's a consumer commodity.

This stuff is as chinese as Mu Shu, so there's no SDS or safety info.

The best I could come up with is a mixture for a spray clarifier minus the propellants:

Acetone, butyl acetate, and methyl isobutyl ketone solvents with a propylene glycol methyl ether acetate or something similar with a lower BP as a surfactant.

I found mixed results with pure acetone on the web, it seems to me that surface prep and wet sanding the factory coatings is the key. Lots of confounding info with very little facts to support it out there. No SDS of course, it's a consumer commodity.

- Joined

- Sep 3, 2023

- Messages

- 238

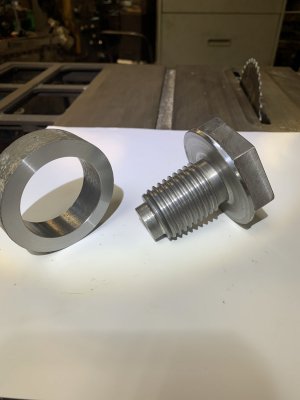

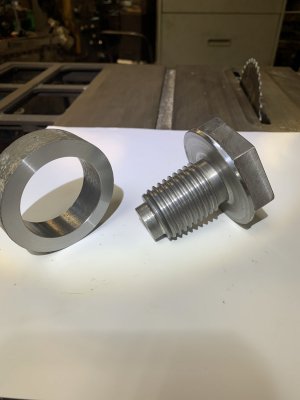

Made a replacement bolt for a beam gantry granite saw. Old one was sloppy in motor arbor from years of use, and head was rusting away.

I made the threads oversized pitch diameter to make up for wear in the motor arbor. Got it to fit on second test fit. Threads are 36mm x 4mm pitch, left handed. Also trued up Blade spacer, and added a oring groove to help act as a lock washer. The operator has had the bolt coming loose lately when starting up.

Sent from my iPhone using Tapatalk

I made the threads oversized pitch diameter to make up for wear in the motor arbor. Got it to fit on second test fit. Threads are 36mm x 4mm pitch, left handed. Also trued up Blade spacer, and added a oring groove to help act as a lock washer. The operator has had the bolt coming loose lately when starting up.

Sent from my iPhone using Tapatalk

- Joined

- Sep 10, 2022

- Messages

- 949

It is finally nice and cool out. So I had a choice today. Trim an oak tree over my garage. Or mount my vise and arbor press to my rolling bench.

Guess what I chose

Vise is done. Next up is the little press.

Cutting oil is my blood.

Guess what I chose

Vise is done. Next up is the little press.

Cutting oil is my blood.