- Joined

- Feb 19, 2014

- Messages

- 112

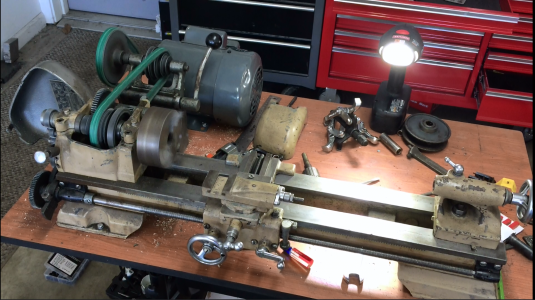

Hey all, I have an old craftsman 101 6" lathe that a buddy of mine generously gifted to me when he got his bigger south bend. It was out of commission for a while because of a few little hiccups and motor problems. I got it running the other day and to my dismay I found that the lead screw power drive (I think thats what you call it im a total lathe noob) doesnt work all the way. The carriage/apron? The part with the cross slide doesnt continue all the way on the lead screw. The threads of the lead screw all galled up in a few spots but not where it stops. Would a new lead screw solve this problem? Also I want to get a new quick change tool post for it, it has a lantern style post right now. From what Ive found as options for tool posts online are very vague. Can anyone point me in the right direction for a quick change tool post for a lathe like this? Thank you in advance.