- Joined

- Mar 20, 2014

- Messages

- 418

I know a lot of you have already made power feeds for your mill, but this may be of some use / help / interest.

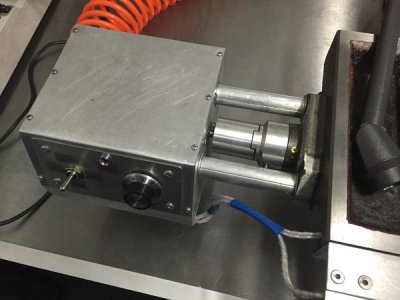

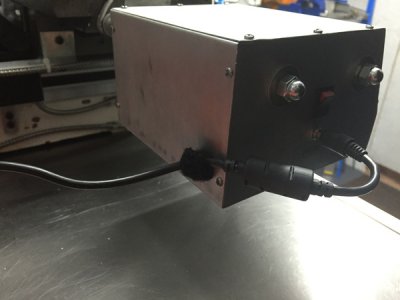

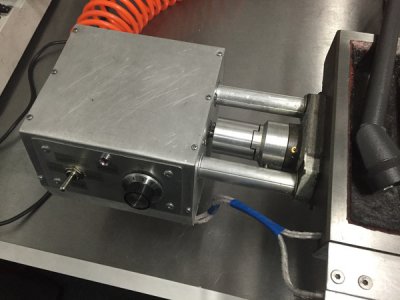

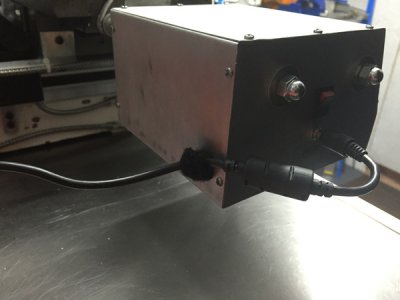

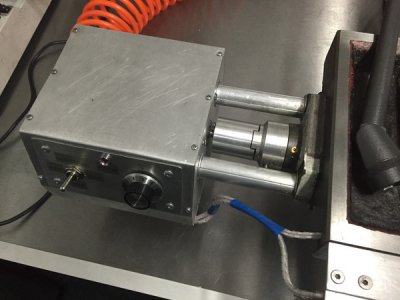

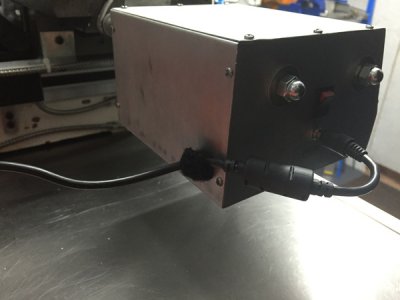

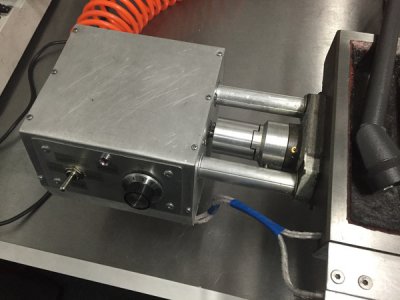

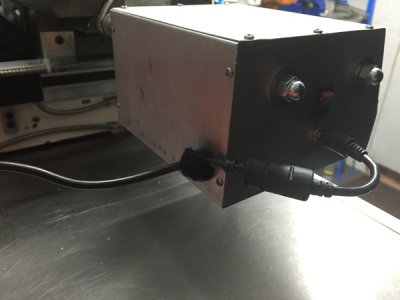

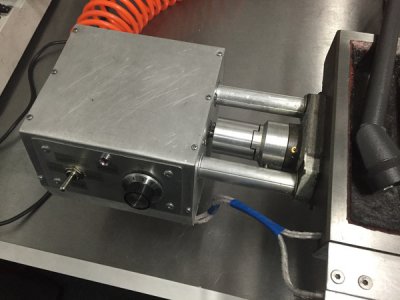

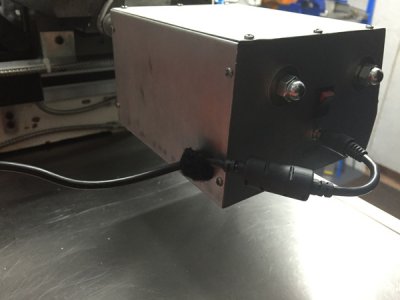

I built my power feed using a 24V 3Amp 150rpm geared motor , an off the shelf PWM speed controller, a 24v PSU and a couple of switches.

The speed controller was one of these:

https://www.kemo-electronic.de/en/T...M171-PWM-Power-control-9-28-V-DC-max-10-A.php

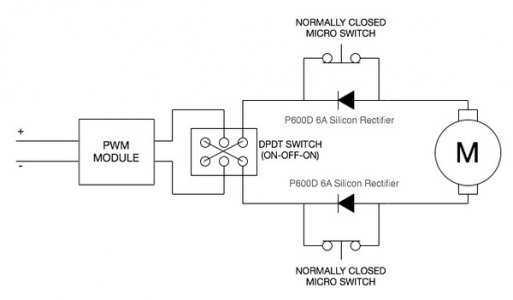

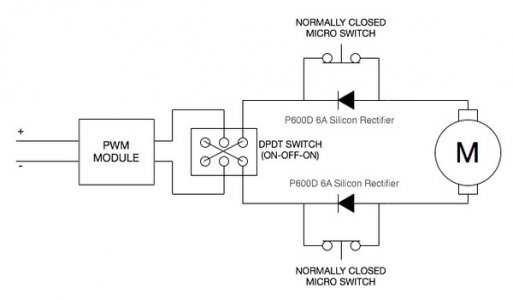

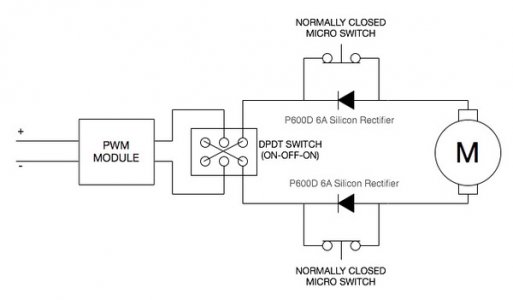

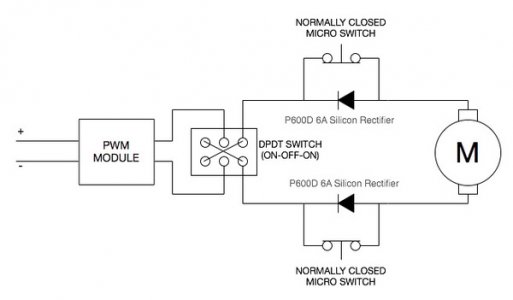

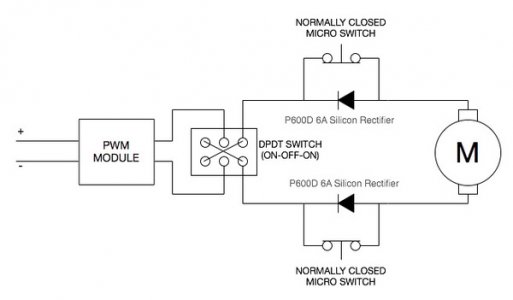

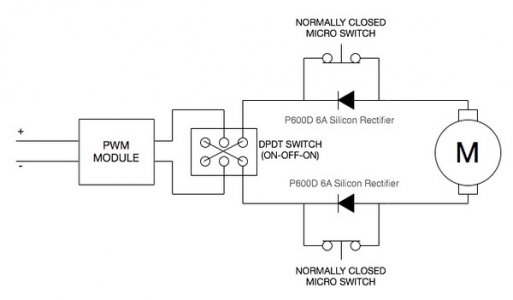

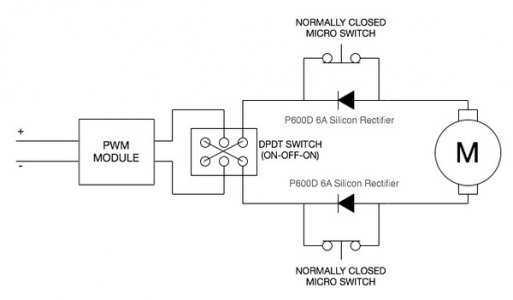

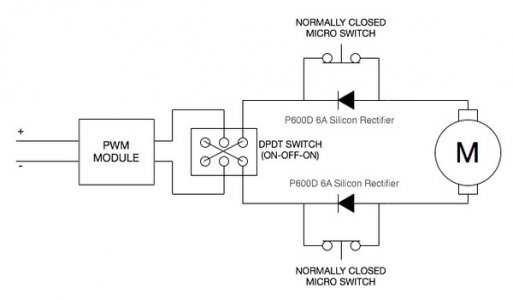

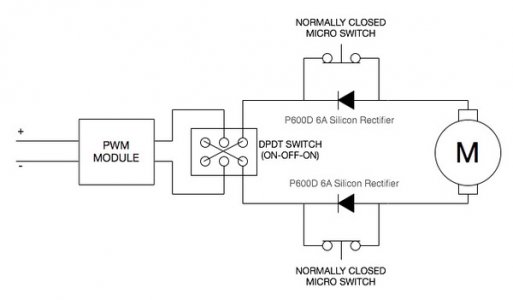

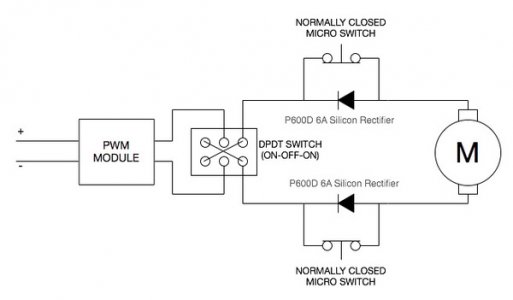

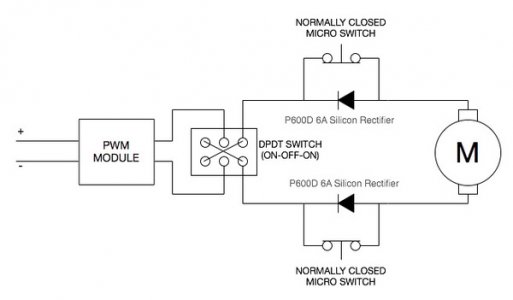

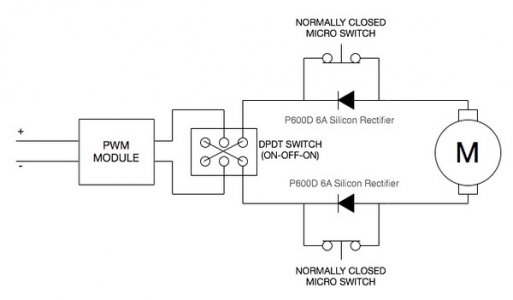

Which came with supplied with the correct potentiometer for the speed control. It was all wired as per this circuit:

This gives you directional control, and limit switches to cut the motor when you hit a stop, but due to the diodes / rectifiers, you'll still be able to change directions and have the motor move the table (or whatever) away from the tripped limit switch.

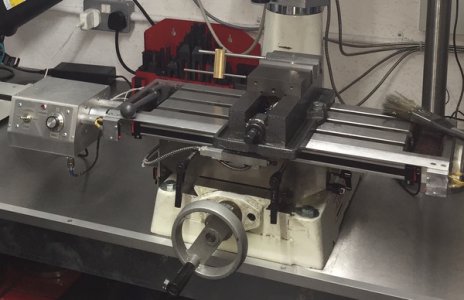

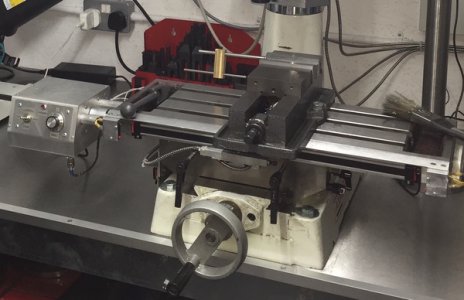

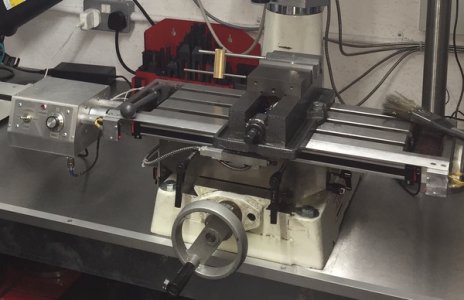

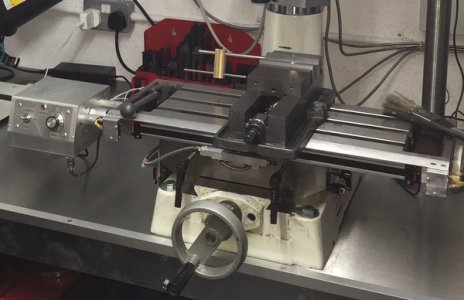

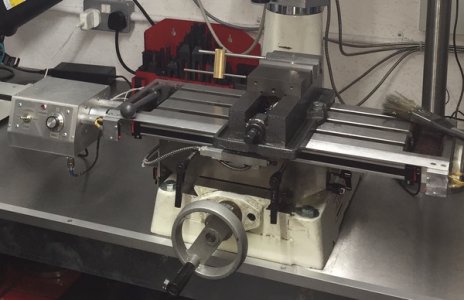

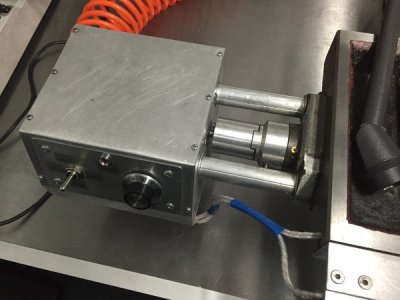

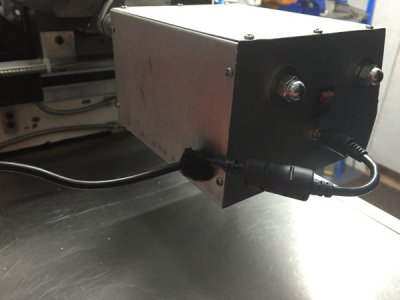

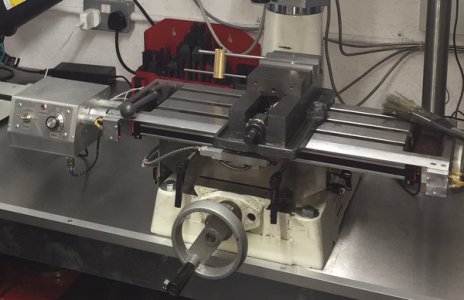

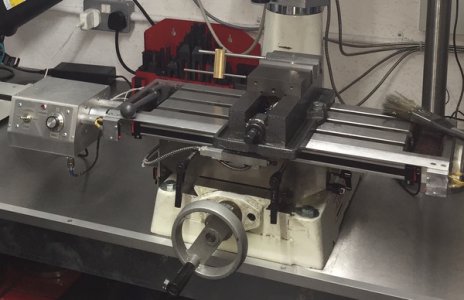

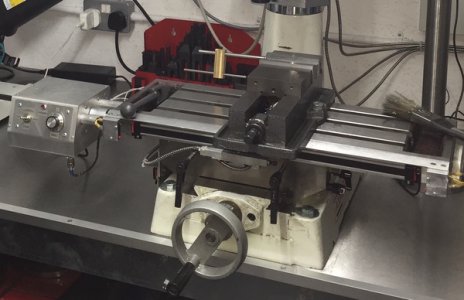

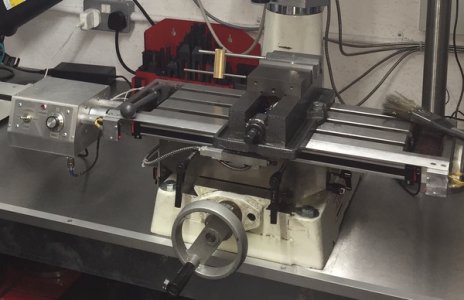

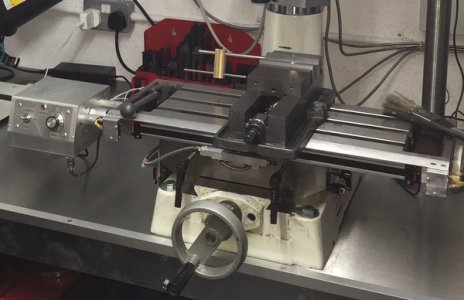

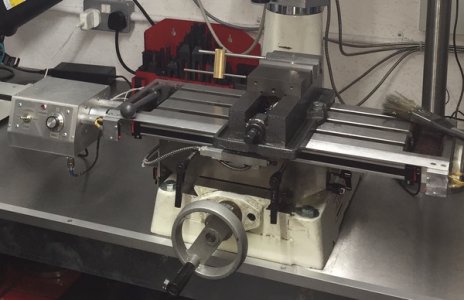

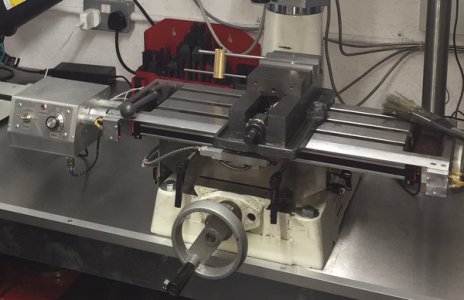

All of it was housed in a shop built enclosure, along with the normal sliding coupling to engage the castle-ated fitting on the lead screw, and the limit switches are mounted to the front of the table.

The table will travel until it contacts the bar that's under the vice in the pic, when it will trip and stop the motion. The position can be fine tuned by screwing in or out the cap head that is in each end of the bar.

It works well - I essentially used the same circuit for the powered head lift / lower, but instead of the PWM module the speed and direction is handled by trigger of the old drill that powers it.

Cheers

Jason

I built my power feed using a 24V 3Amp 150rpm geared motor , an off the shelf PWM speed controller, a 24v PSU and a couple of switches.

The speed controller was one of these:

https://www.kemo-electronic.de/en/T...M171-PWM-Power-control-9-28-V-DC-max-10-A.php

Which came with supplied with the correct potentiometer for the speed control. It was all wired as per this circuit:

This gives you directional control, and limit switches to cut the motor when you hit a stop, but due to the diodes / rectifiers, you'll still be able to change directions and have the motor move the table (or whatever) away from the tripped limit switch.

All of it was housed in a shop built enclosure, along with the normal sliding coupling to engage the castle-ated fitting on the lead screw, and the limit switches are mounted to the front of the table.

The table will travel until it contacts the bar that's under the vice in the pic, when it will trip and stop the motion. The position can be fine tuned by screwing in or out the cap head that is in each end of the bar.

It works well - I essentially used the same circuit for the powered head lift / lower, but instead of the PWM module the speed and direction is handled by trigger of the old drill that powers it.

Cheers

Jason