Probably don't want to weld to the van's sheet metal floor. Also skip the factory sheet metal cabinet/stand. Design a square tube steel stand that gets bolted through the floor to the van's frame in four places. Put the lathe against the wall behind the driver and provide for some access for those limited times it is needed, by unbolting something and swinging it out. Get creative.

Let me consider some of the advantages and disadvantages of putting the lathe directly behind the driver.

(1) I would definitely have 2 or 3 vertical chromoly columns to protect the driver from the lathe surging forward in the event of an accident. These columns would be directly behind the seat when it is moved all the way back. That is easier than adding protective columns for a lathe on the passenger’s side. The 2 collision scenarios are a high speed head on collision & me back ending someone at a high rate of speed, so the protective columns will have to be pretty large because those scenarios would be projecting the bed into my spine.

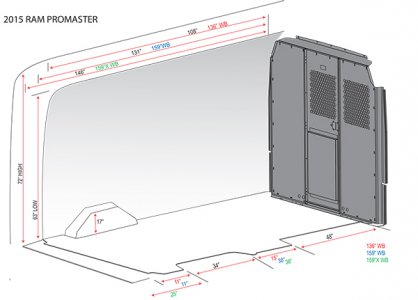

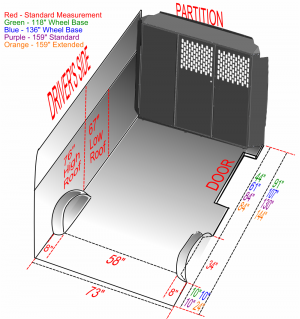

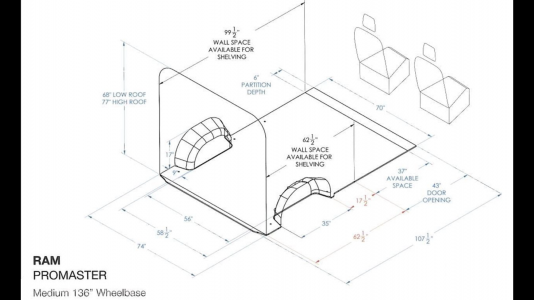

(2) I need to leave just enough room to get the tailstock in and out. Like I said, the chip tray can hang over the wheel well a little bit.

(3) Accessing the rear of the headstock for the occasional electrical repair would require unbolting the lathe (at the chip tray) & swinging it out for the service job.

(4) I need to leave the area above the driver’s wheel well clear for access to the change gears and long work pieces placed through the spindle. I will probably just leave a clear space all the way to the back; this van is not long, so that is only another 8 inches.

(5) With no passenger seat and no cargo partition, the rest of the floor plan is open country where the following items are needed:

(a) inverter and battery (or two),

(b) work table and chair.

(c) tool cabinet (like I said, I want this to swallow up the passenger’s side wheel well and rise to the ceiling).

(6) Since the lathe operator is facing the lathe with the passenger’s side sliding door behind him, the passenger’s side sliding door is the emergency exit. This is good because I need to block the rear doors with the work table and chair.

The battery (or two) can go behind the lathe (in my garage, I have a garbage can in that space now). I don’t know where I would mount the inverter.