I've got an older, 25years, 20 ton press that may be a HF. It is much stouter than the ones they sell now.

DRO?? I've got them on both lathe & mill and really like them, especially on the mill. Required... NO! You can always add one latter and for less $.

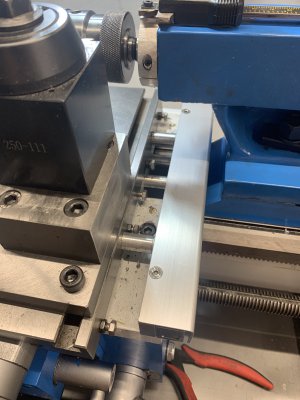

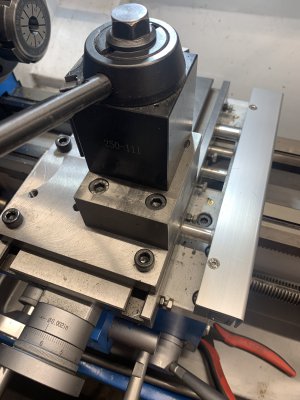

Inserted tooling is fine but the really good stuff is expensive. I have a set from PM that is OK, included a couple of boring bars. Most of the time I use HSS that I grind. It's not rocket science to grid an acceptable edge. You will want additional tool holders. One for every tool. Most of mine are from Shars when they put them on sale. I use my PM 5C collet chuck a lot. It's sort of a toss up on whether to get 5C or ER. I got the 5C because I've got other things that the collets fit.

Other things: tap & die sets (good ones, not from the hardware store) 115 piece set of quality drills, I also have a set of screw machine drills that I use more than the jobber drills. Set of 60 & 82 degree center drills. Lots of measuring devices, adjustable parallels, thread pitch, fishtail, angles, depth, height, micrometers, bore measuring, 6" scale, bench grinder, band saw, gage pins ... buy as you find a need.

MsMaster-Carr carries a lot of supplies

I'm older than dirt, retired, and mostly repair things. Make parts that are no longer available. I have a casting setup for aluminum, brass & zinc that allows me to make some parts that would be really difficult or impossible for me to machine from solid. I like the challenges, might even slow down an old mind going to hell.